Constructing the Cheops Pyramid Through Multispiral Ramps

The Cheops Pyramid is the largest Egyptian pyramid and is therefore also known as the Great Pyramid.

The construction of the pyramid is not a mystery.

It is a masterpiece of organization, efficiency, and engineering logic.

This website invites you to explore a theory that finally makes sense —

not through speculation, but through deduction and mass logistics.

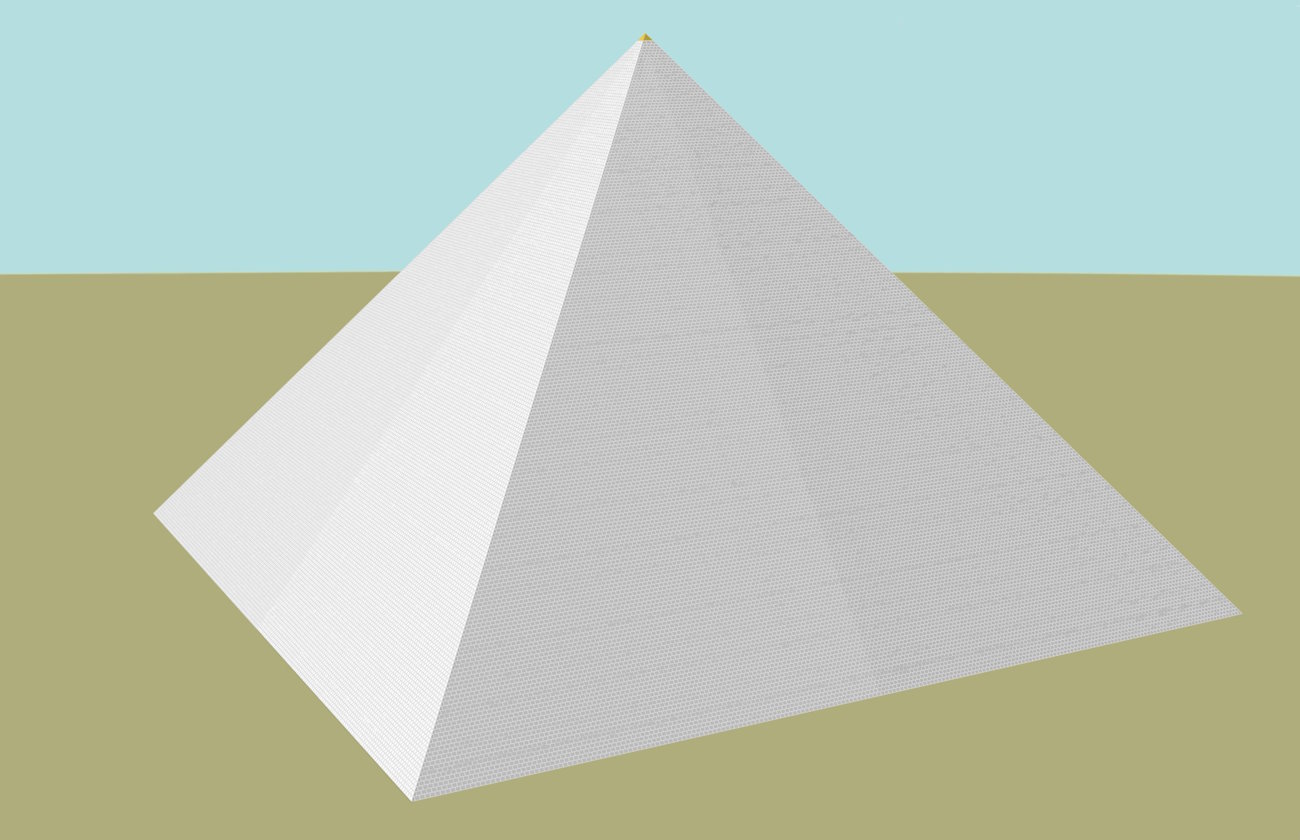

The image from Mozaik Education shows the Pyramids of Giza from 4500 years ago. There is also a 3D representation of this.

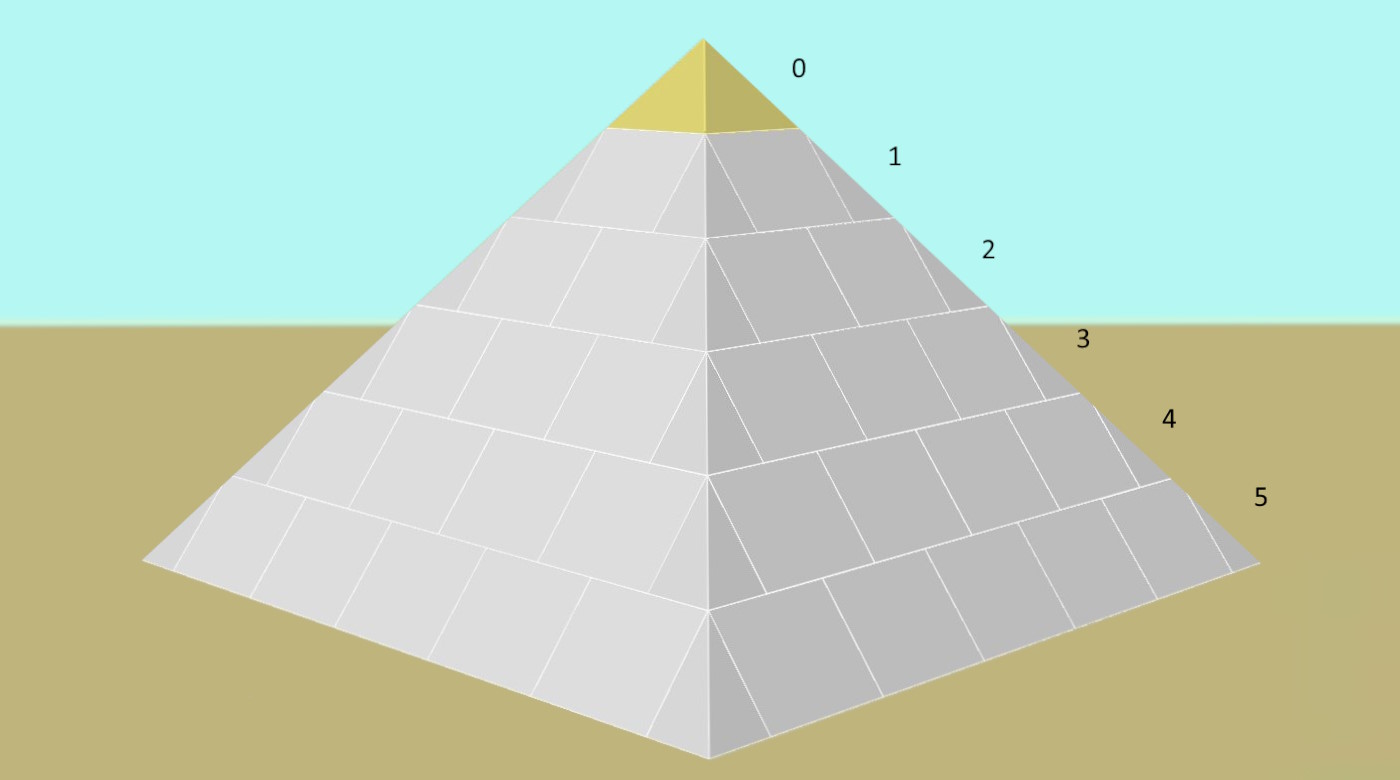

The casing out of white limestone made the pyramids appear like diamonds in the sunlight.

Overview

External Ramp

Internal Ramp

Theory of Multispiral Ramps

Uniform Pyramid

Ramp Construction

Multispiral Model

Towing Team

Construction Time

Workforce

Turning At Corners

North Entrance

Huge Blocks

Zigzag Lifting

Pyramidion

Outer Casing

Eight Sides

Magnitude

Real Pyramid

Stability

Measurements And Precision

North-South Direction

Circle Number

Pyramid Height

Strategy

Seven Historical Evidences

Summary

Seven Misfortunes

Archaeological Finds

Interviews with AIs

Publications

- Although the Great Pyramid is one of the most impressive structures of mankind, there are almost no documents or archaeological finds that indicate its construction technique.

- The pyramid builders belonged to a high guild, which probably kept their knowledge extremely to themselves. They made sure that all notes were destroyed.

- According to the two historians Herodotus and Diodorus, the construction time was only 20 years.

- How could the Egyptians in the Old Kingdom build this pyramid?

There are many theories about this. However, most of which are completely absurd and none of them can explain the construction completely and satisfactorily.

Therefore, this problem is considered as a mystery of mankind.

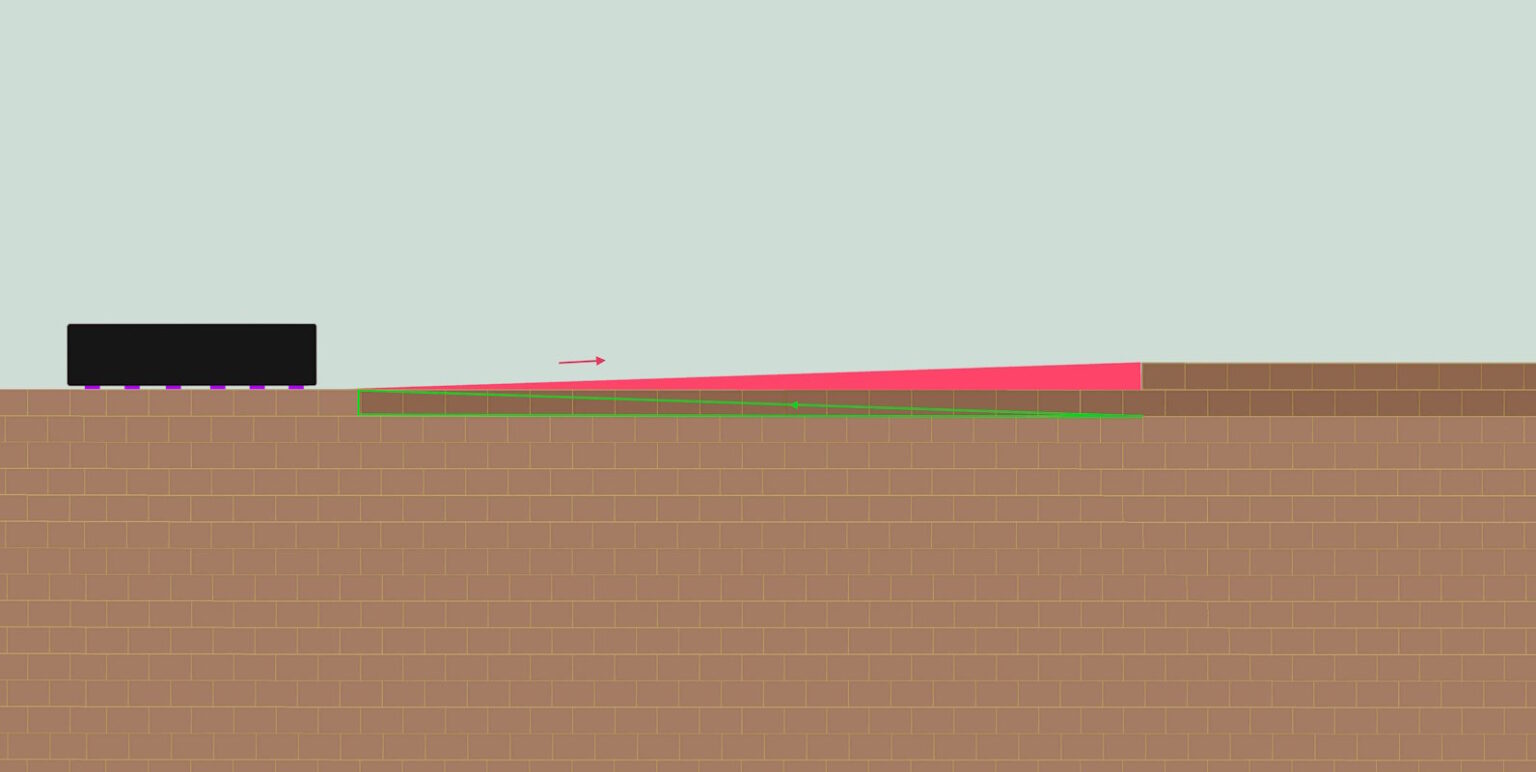

External Ramp

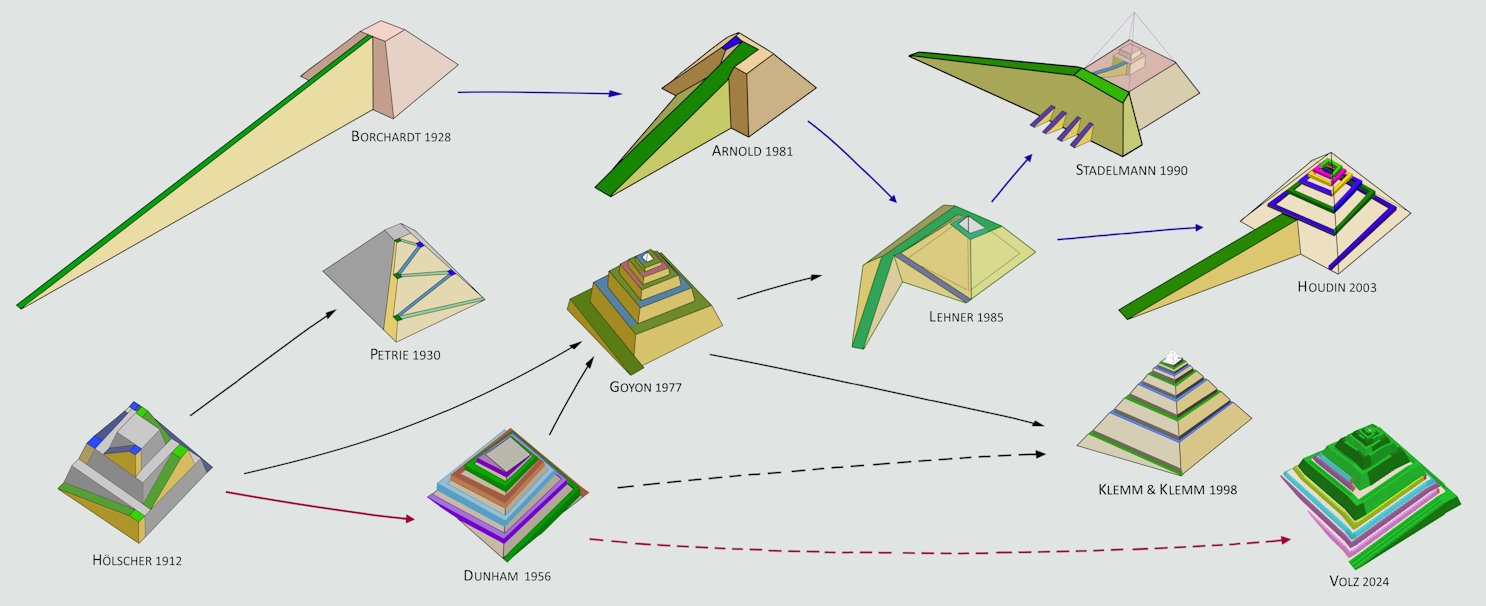

Using an external ramp seems to be the most immediate method. This ramp model was proposed by Ludwig Borchardt in 1928.

With an inclination angle of 6.6 degrees or 11.6 %, the ramp would have a length of 1.3 km and a volume of 160 % relative to the pyramid.

Since the two neighboring pyramids did not exist at that time, the ramp could have looked like demonstrated in the image. This is probably the only way to place an external ramp in this landscape.

- It would take more than 10 years to remove this ramp. Therefore, it is impossible to complete this monument within 20 years

- If this critical time limit would not exist, then the external ramp would have been considered as a possible solution to the problem for long.

Internal Ramp

In 2003, Jean-Pierre Houdin introduced his theory of the internal ramp, which uses two separate ramp systems.

This theory has generated great fascination wordwide through computer simulations. However, the crucial aspect, namely functionality, is never questioned.

1) A straight external ramp leads to 30 % of the height, what allows to install 65 % of the material.

2) The remaining material is installed using an internal ramp, which requires a second technique.

The internal ramp, which is 2.6 m wide, has only a single transport lane. Therefore, the construction of 35 % of the material would take at least 20 years. Thus, the total construction time of the pyramid would be at least 30 years. To achieve the unavoidable construction time of 20 years, there would have to be an average of more than 2.5 transportation lanes in the upper 70 % of the pyramid. See the Construction Time section.

3) In the upper 15 % of the pyramid, the inner ramp technique leads to a dead end (light green). Space within the pyramid becomes increasingly limited, and the tunnel project cannot continue. Therefore, the construction of the uppermost part of the pyramid and the setting up of the pyramidion must be accomplished using a third technique.

4) For the way back, a wooden frame (dark green) is installed, which represents a fourth technique. The wooden frame rests on the stones of the outer casing and is only supported by the bosses of these stones, what is a high risk of accidents.

5) For the smoothing process of the outer layer, an additional wooden frame must be attached around the pyramid, which must be moved from top to bottom according to the smoothing process.

A construction method using at least five different techniques contradicts completely the customs of the Old Kingdom, according to which the construction method was simple and uniform. Only in this way could thousands of workers be organized.

Overall, the theory of the internal ramp is ideal for a fantasy film, but from a scientific point of view, it is a deception based on computer simulation.

Therefore, other solutions must be found.

Theory of Multispiral Ramps

This section contains the essential informations on the Theory of Multispiral Ramps. Detailed information, including calculation tables, is provided below.

- The construction of the pyramid was the largest and most important project in the state.

- This required a clear and controllable technology, otherwise the project would never have been started.

- The pharaoh had to be alive when the pyramid was completed.

Therefore, the construction period was set at 20 years.

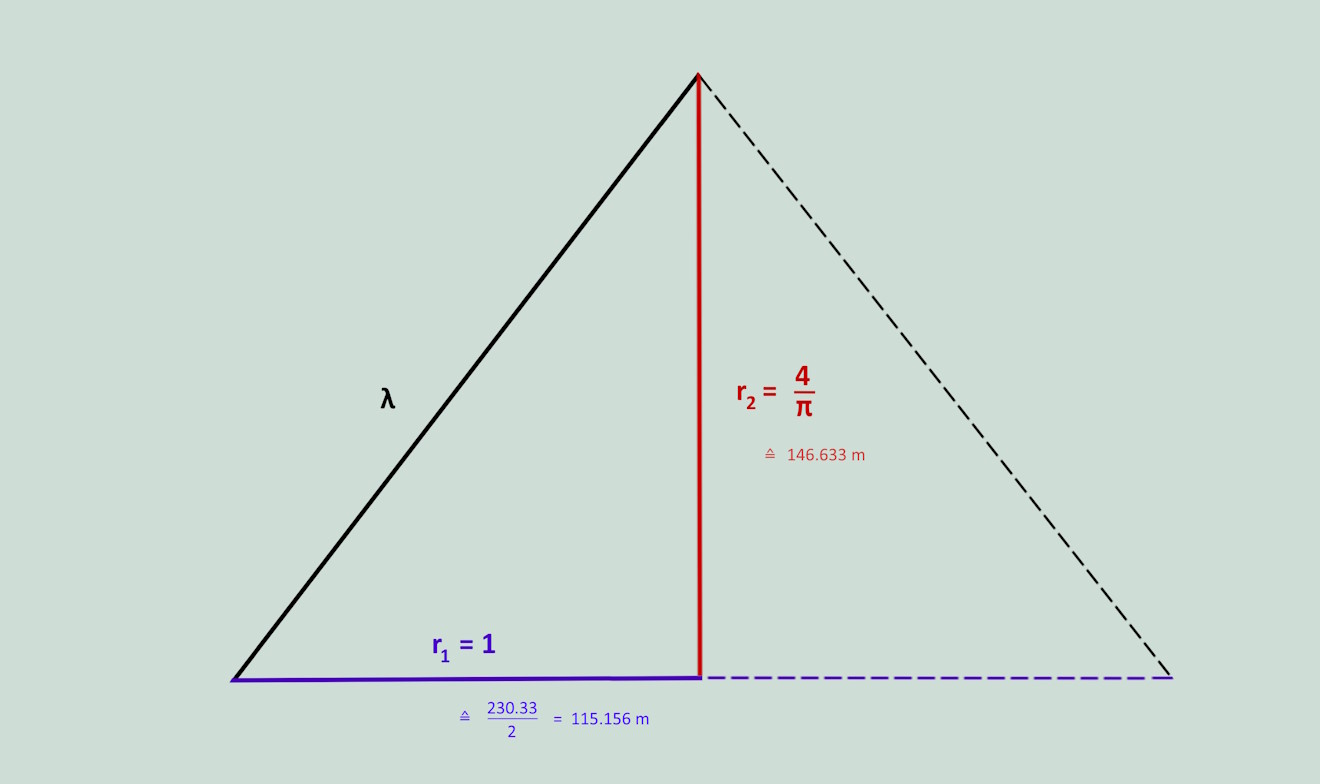

See the Strategy section. - The slope of the pyramid was determined for symbolic or political-religious reasons:

Slope = 4/π

See the Pyramid Height section. - Then the task was to build the largest possible pyramid in this format.

There were two limitations:

– Construction time of 20 years,

– Average number of workers of 12,000 under normal working conditions.

See the Workforce section. - This determined the height of the pyramid to be 146.59 m.

- Overall, this is an early optimization problem:

To create the largest possible pyramid under certain constraints.

This task could only be solved by the earliest mathematicians. - A precise construction plan and schedule had to be submitted, specifying which height would be reached at what time.

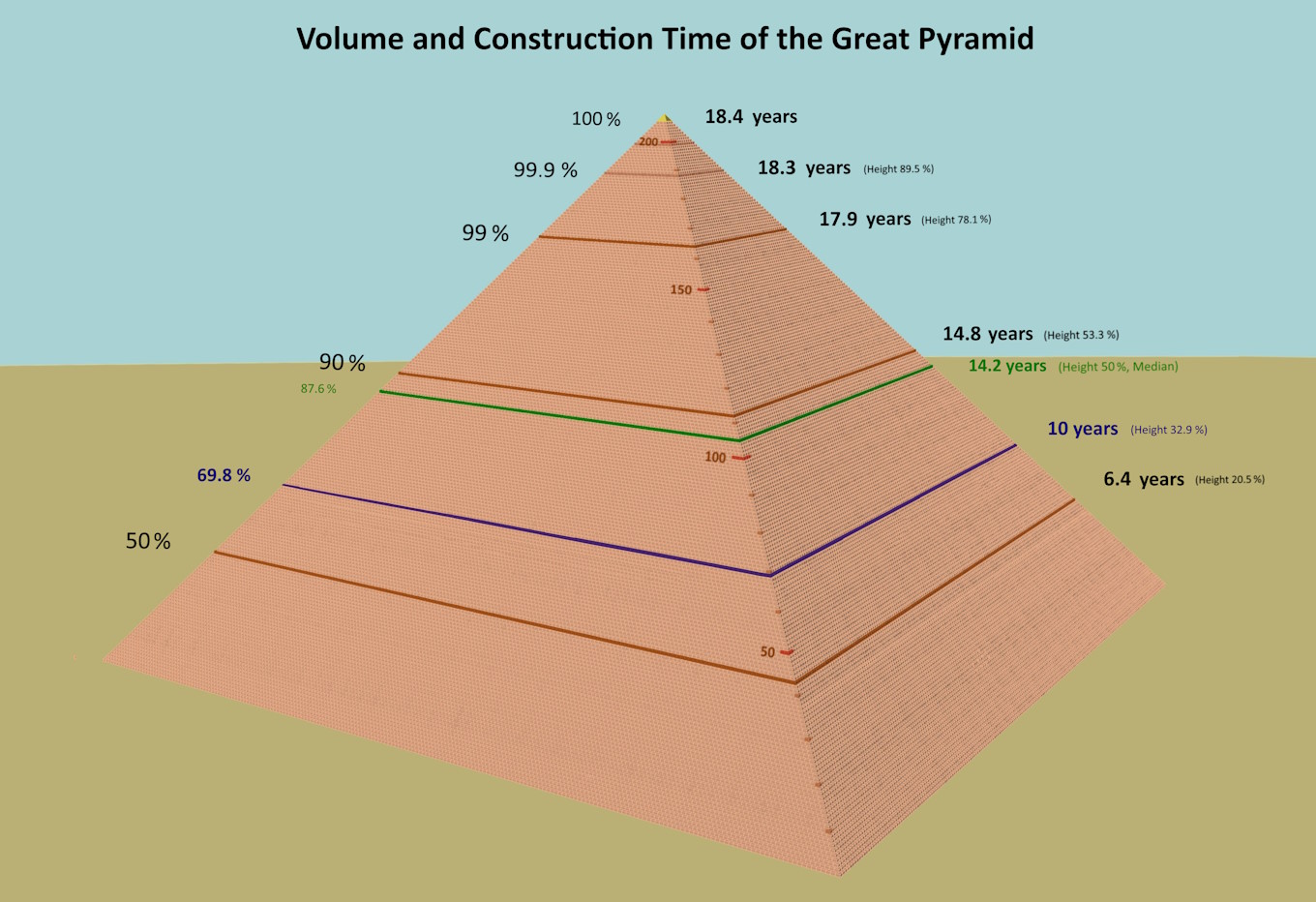

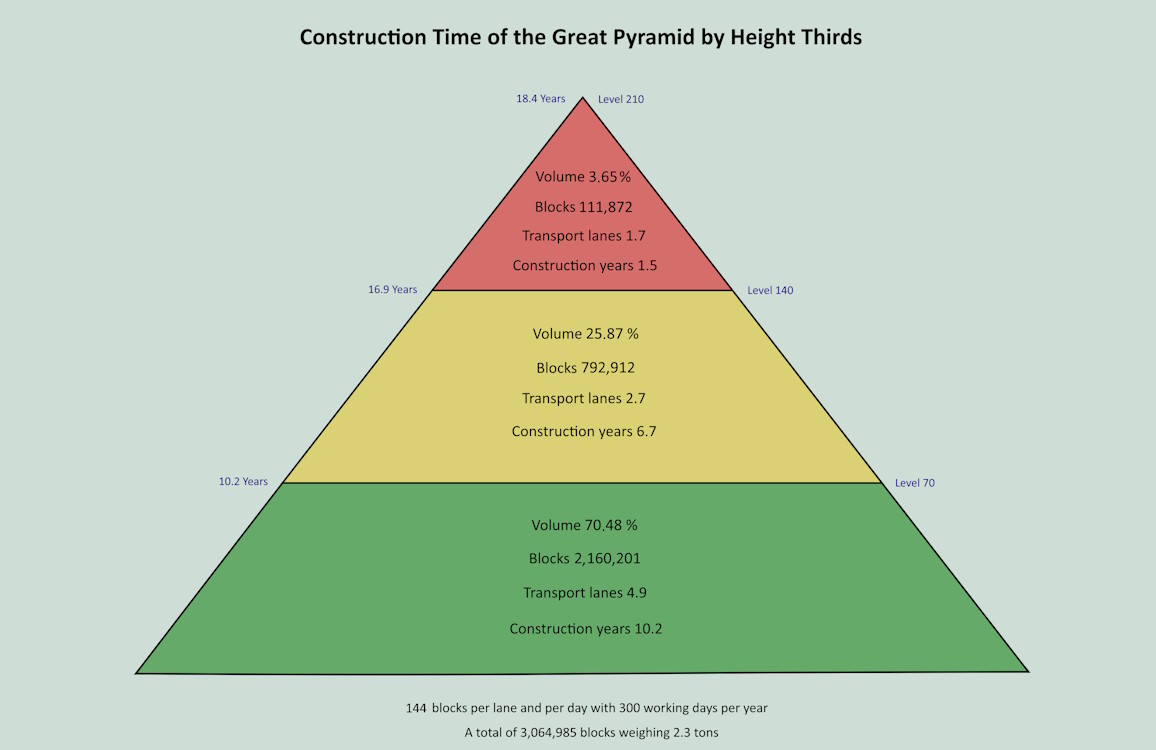

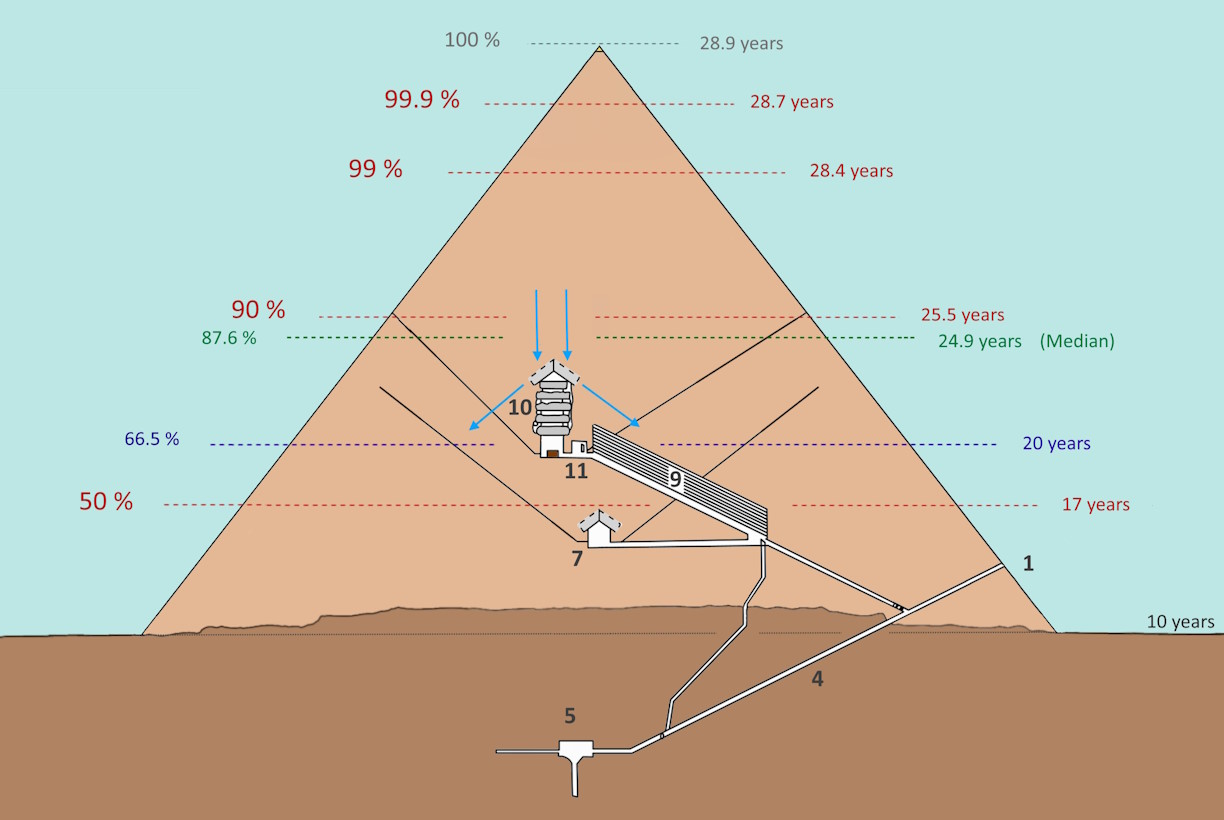

For example, „After 10 years, one third of the height will be reached and 70 % of the material will have been used.“

See the Overview Image. - Therefore, the most efficient method had to be applied at every stage of the construction process.

Deciphering the construction process is therefore quite analogous to convergent evolution in biology. - Using several spiral ramps is the most efficient construction method:

– The system has sufficient delivery lanes,

– There is a separate return path to avoid collisions,

– The delivery of stone blocks and the construction of the ramps can be carried out independently of each other,

– The ramp material accounts for only 6 % in comparision to the pyramid’s volume.

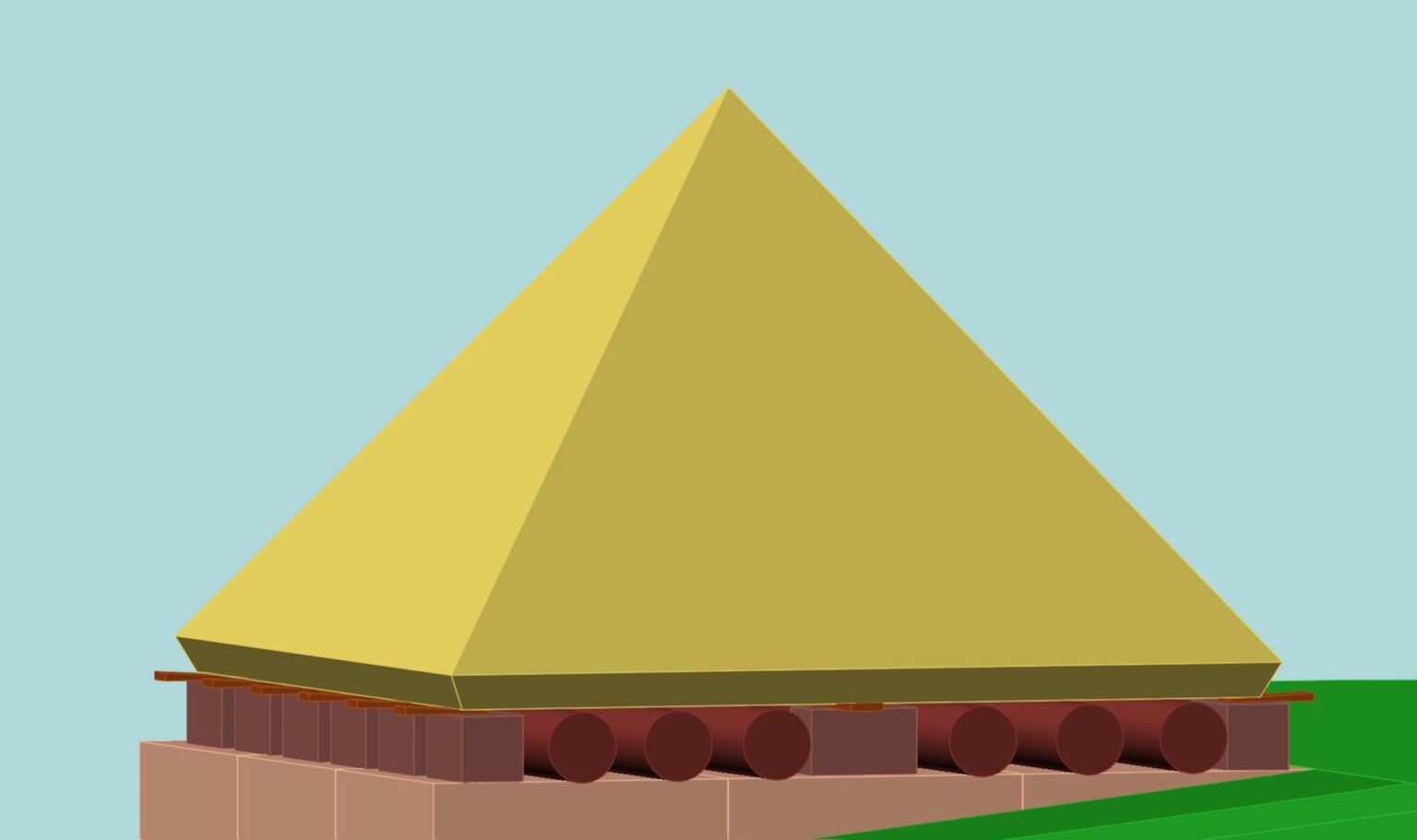

See the Ramp Construction and Multispiral Model sections. - The transport method using wooden rollers is the most efficient.

The method using sliding sledges on wooden beams also requires numerous water carriers and wider ramps.

See the Towing Team section. - The construction method follows a simple and uniform line, as was common in the Old Kingdom.

- The multispiral ramp theory is the first coherent and complete proposal for the construction of the Great Pyramid.

This was published in 2024.

See the Summary section. - The construction method is consistent with the few archaeological finds and historical evidences.

See the Seven Historical Evidences section. - The task of future archaeologists will be to examine the outermost layer of the pyramid for ramp traces.

See the Archaeological Finds section.

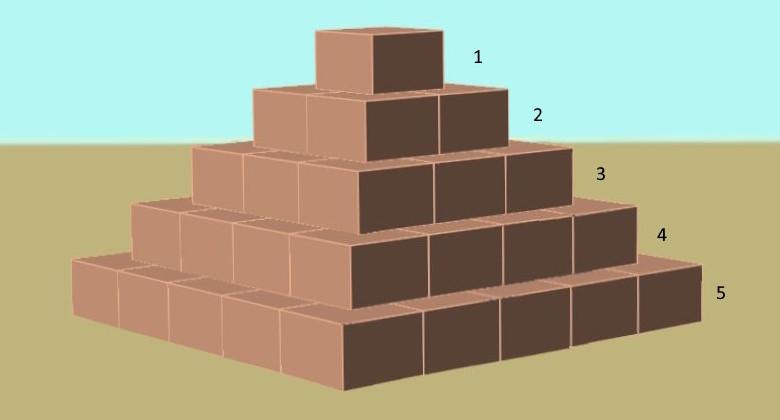

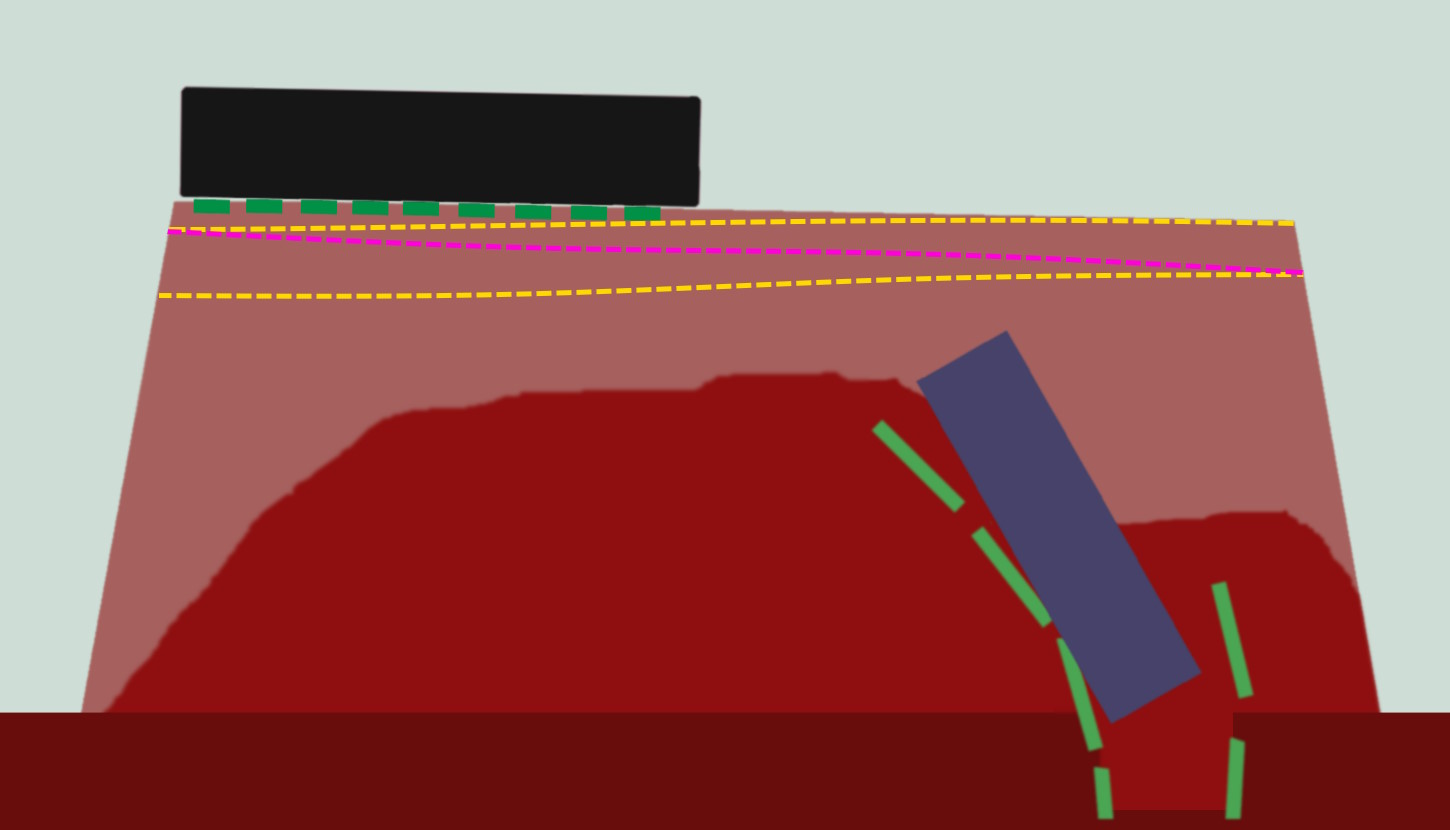

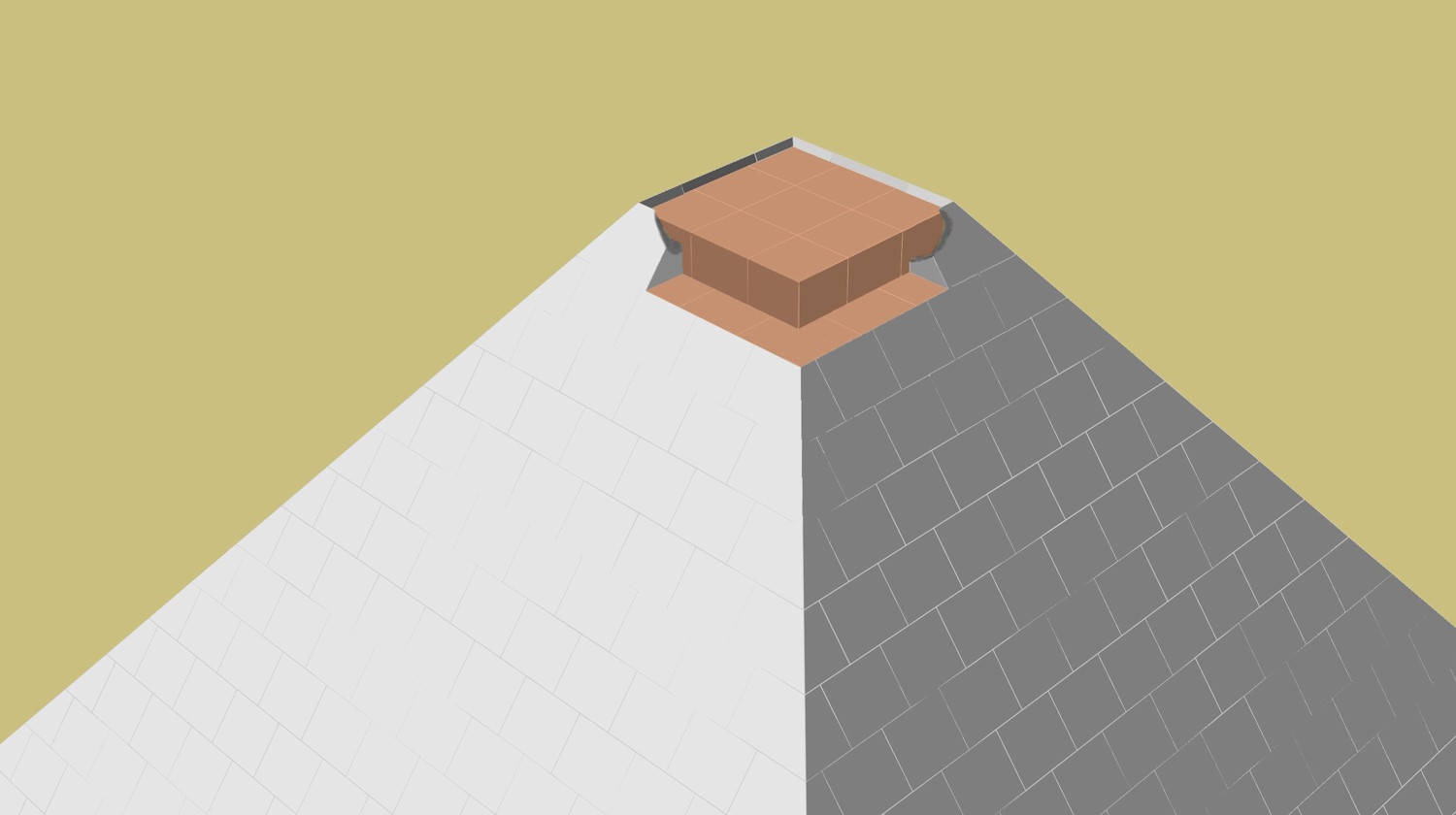

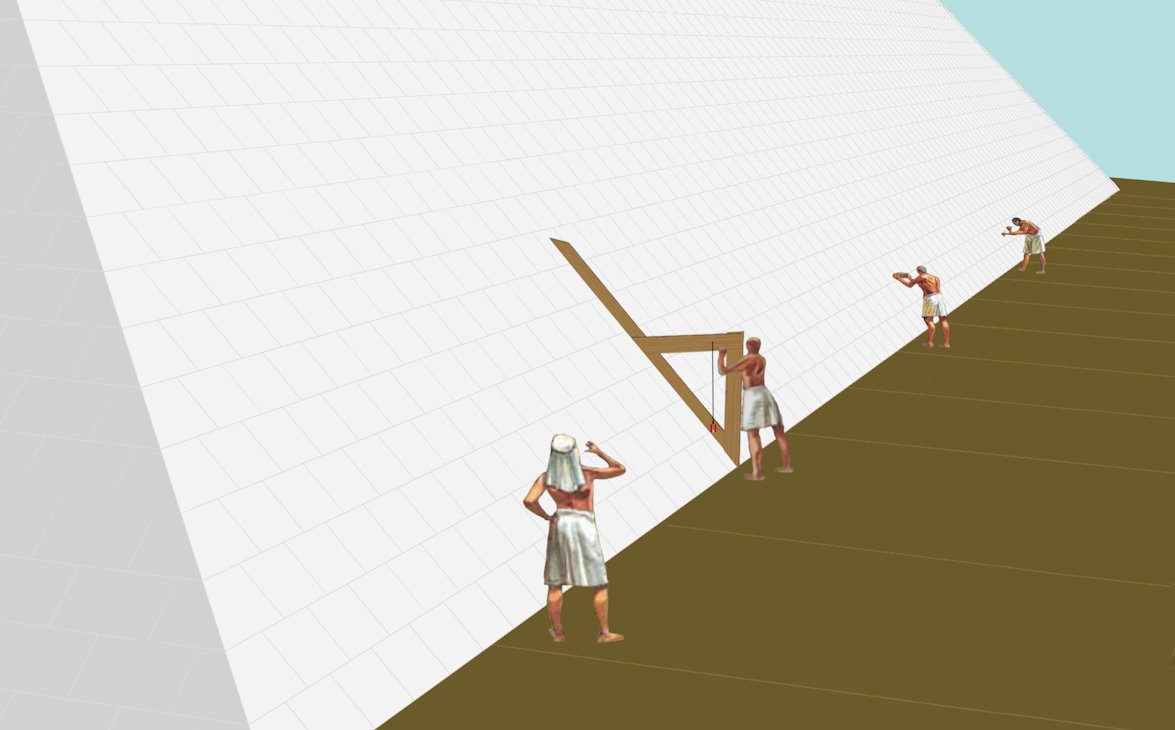

Uniform Pyramid

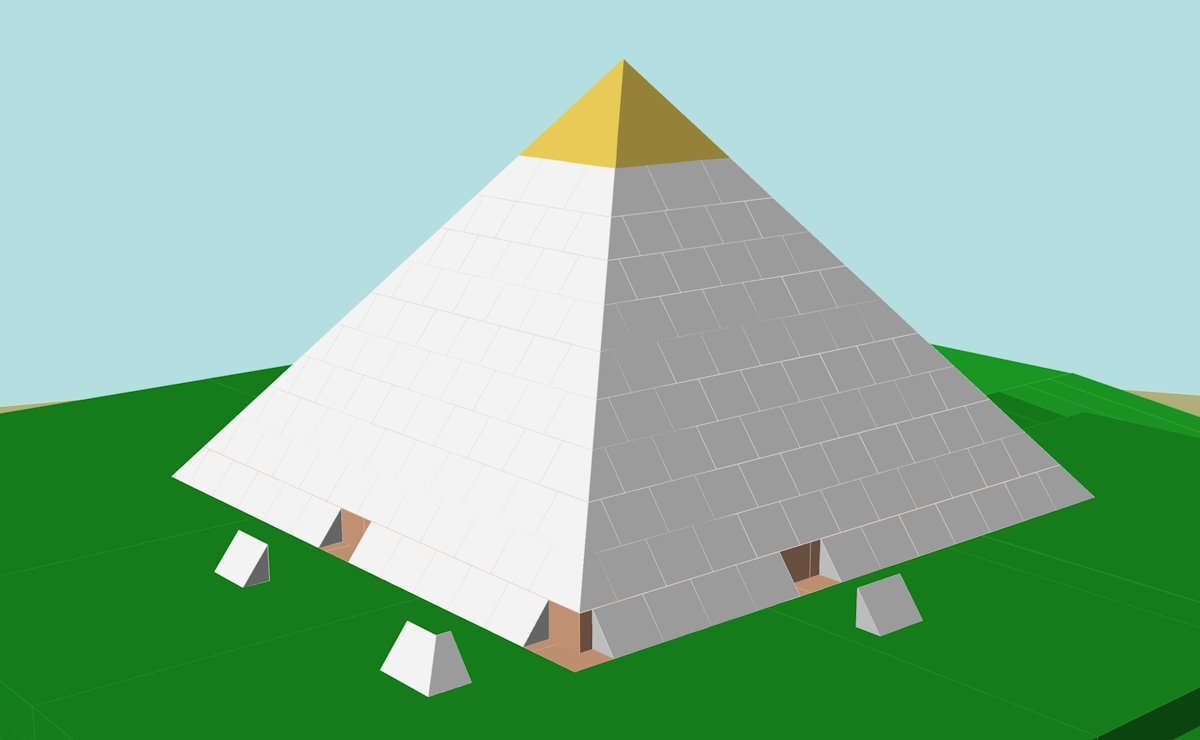

Then the inner step pyramid is decorated with an outer casing. The corner and deco stones of the casing are placed on the steps of the inner pyramid.

There is an additional level with a gold-plated keystone at the very top. This stone is a mini pyramid and is called pyramidion.

The Great Pyramid consists of 210 levels including the Pyramidion. As a uniform pyramid, the Great Pyramid would have 3 million blocks.

The lowest red line indicates the height at which half or 50 % of the material was installed. This process took 6,4 years and only a height of 20.5 % was reached at that point.

The blue line shows the height after half of the construction period or after 10 years, where one third of the height has been reached and 70 % of the material has been used.

The green line stands for half of the height or the median. This construction phase was reached after 14.2 years.

Thus, for many years the Pharaoh saw only a truncated pyramid which did slowly grow.

A uniform block of the Cheops Pyramid is 1.1 m wide, 0.7 m high and weighs 2.3 tons.

The Great Pyramid is by no means uniform. The blocks inside are very irregular.

Using a model of a uniform pyramid, the calculations can be presented more clearly. The uniform block provides a unit of measurement for the amount of material produced and installed.

However, this does neither change the total amount nor the position of the material installed.

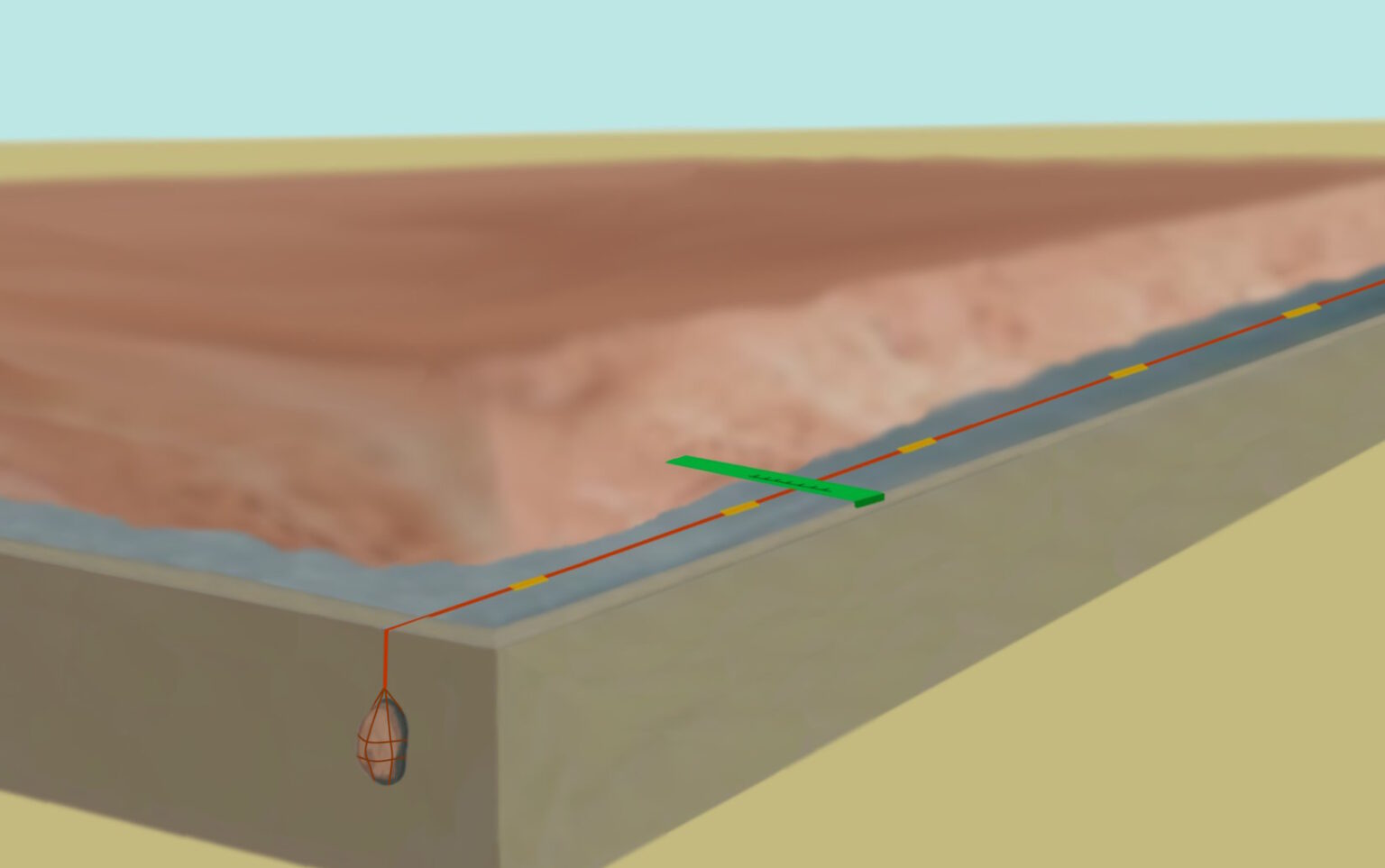

Ramp Construction

The ramp paths are directed parallel to the sides of the pyramids. The first element rests completely on the earth’s surface. The next higher element is shifted towards the pyramid by half a block width.

A transport lane is 3 blocks wide, which corresponds to 3.3 m. This provides sufficient space to transport the blocks.

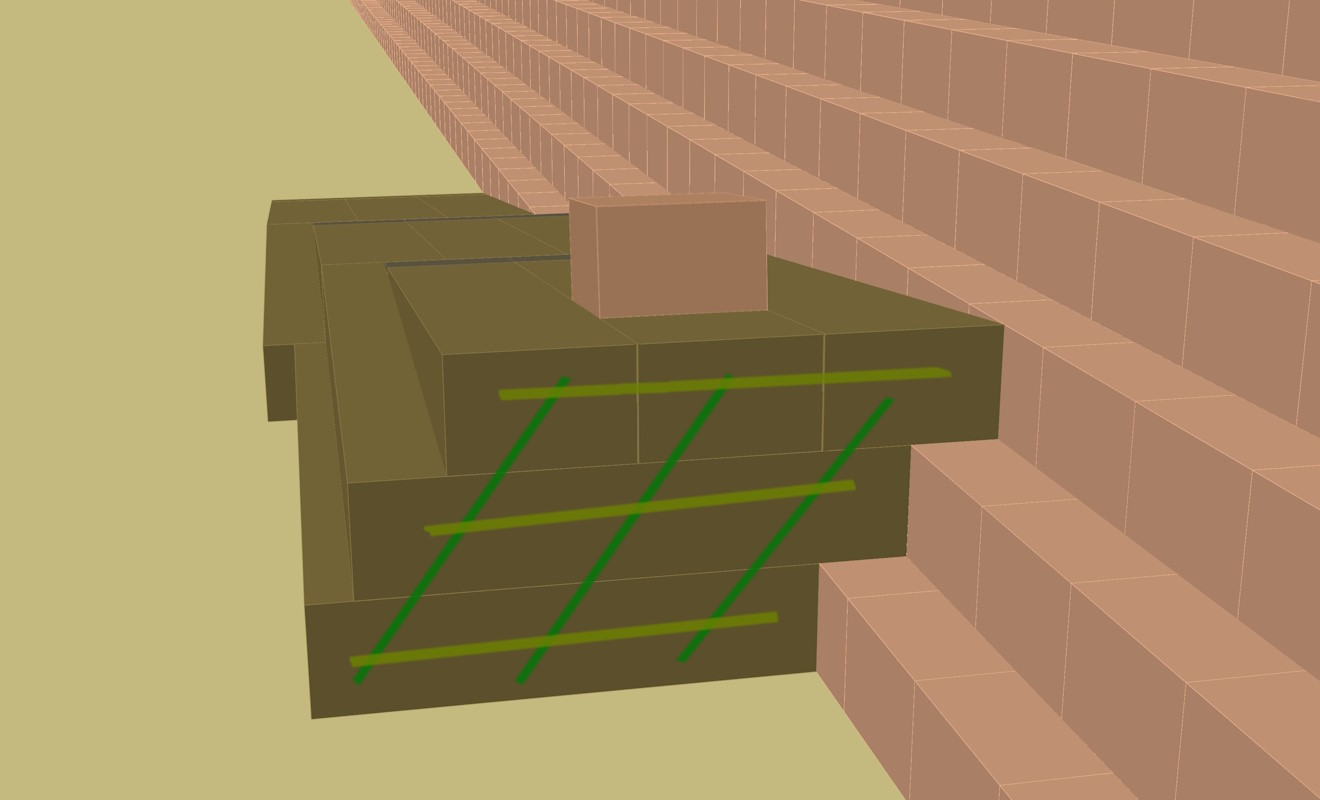

The ramps are built from air-dried mud-bricks. This is an abundant and solid building material

Reed stems, branches and other plant material are installed between the bricks, which are shown in green. This ensures that the ramps hold together, similar to the steel mats in concrete.

The ramps were built using dried mud-bricks, which were transported using the chain principle. This transport method is 6 times more efficient than the sledge and wooden roller method. See the Towing Team section.

Since a brick weighs around 8 kg, it can be assumed that many workers under the age of 14 were used.

Parallel ramps not only have the advantage that they require less material than perpendicular ramps, but also that the stone blocks can be delivered independently of the construction of the ramps. Two delivery lanes for the blocks are shown in orange.

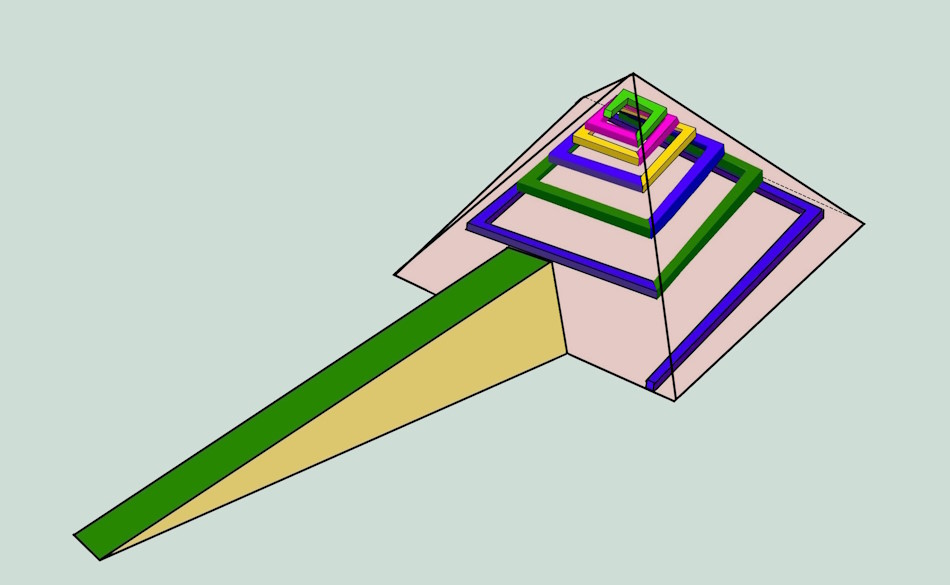

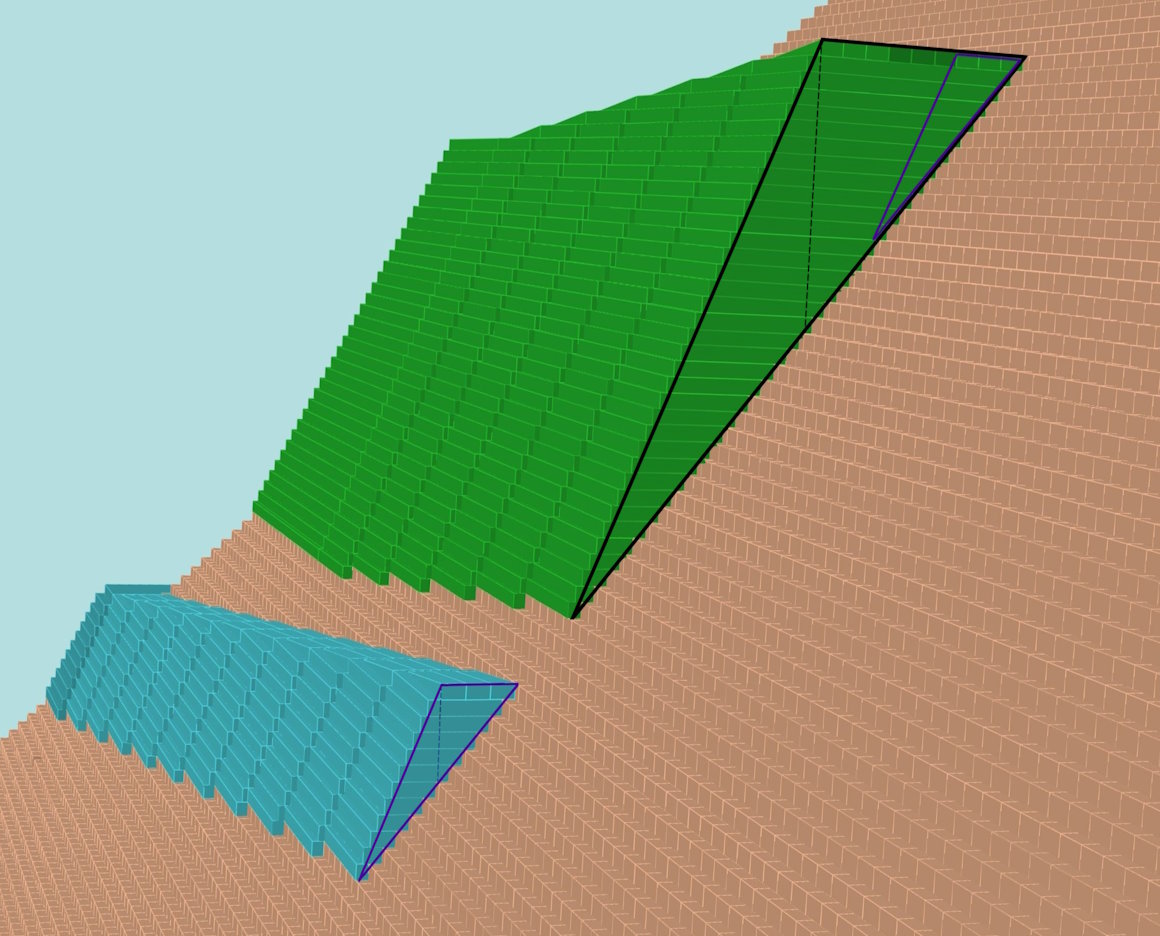

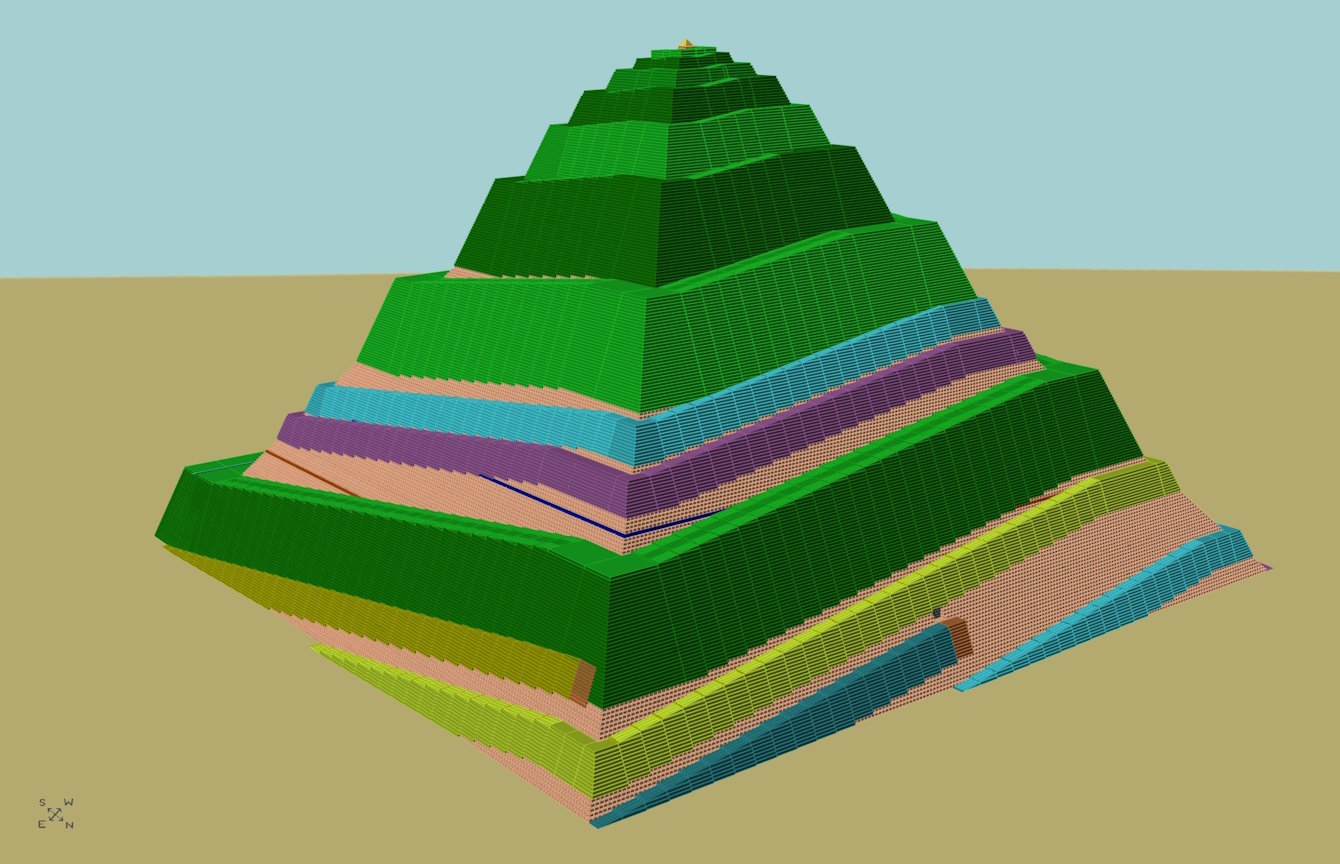

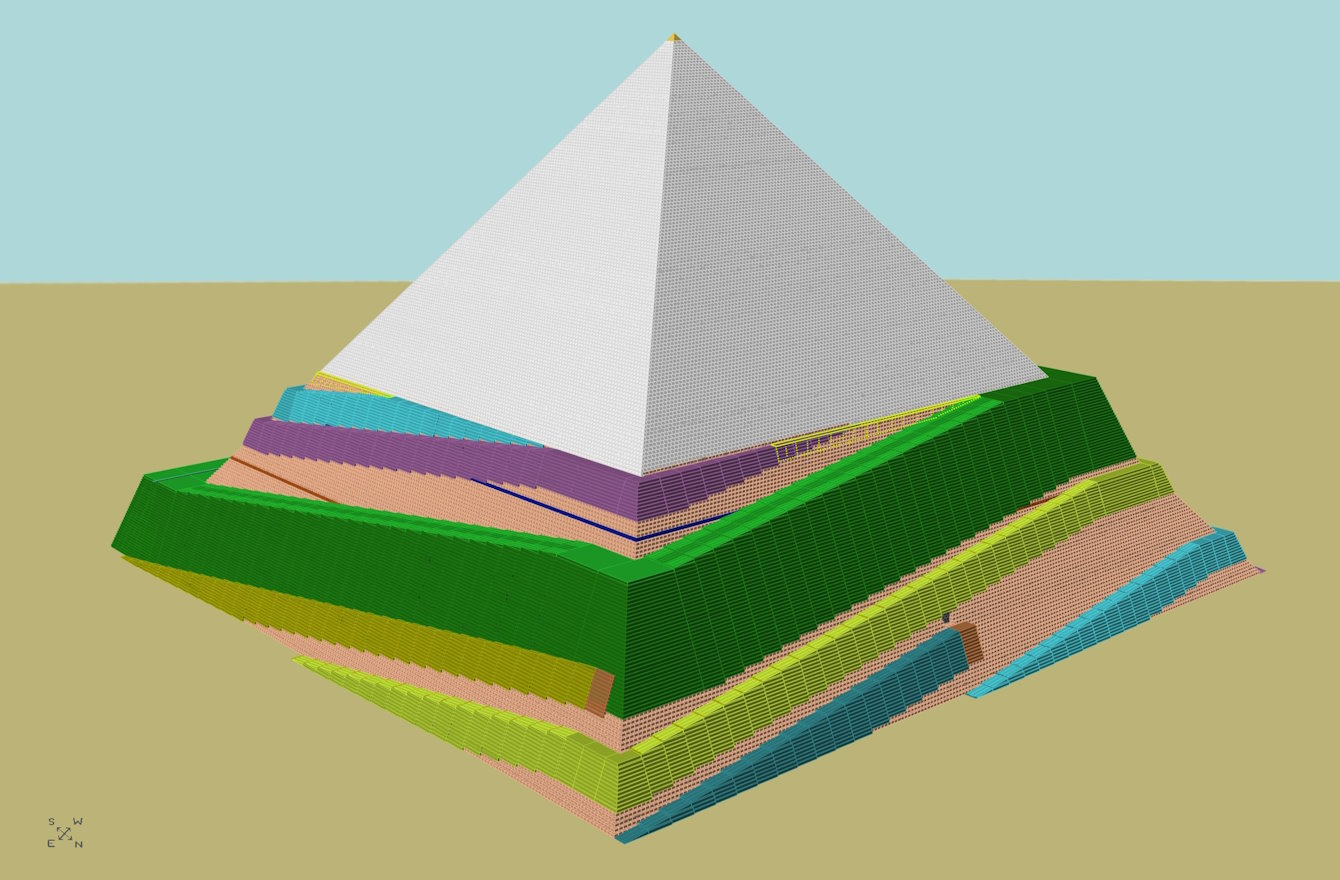

The image shows a cross section of two ramp paths. In order to better distinguish the individual paths, they are shown in different colors. The natural color would be brown.

The light blue path consists only of a transport lane and is 3 blocks wide. The green path is 9 blocks wide and therefore consists of 3 parallel transport lanes.

The black triangle can be viewed as a stretch of the blue triangle in 2 dimensions by a factor of 3. The area of the black triangle is therefore 9 times the area of the blue triangle.

As a consequence, the green path with 3 transport lanes requires 9 times as much ramp material as the light blue path. Both paths have the same length.

In order for a ramp model to require as little ramp material as possible, it must not consist of one wide path, but rather of several narrow paths.

- The ramp slope of 6.6 degrees was chosen so that the ramp elements run in the same rhythm as the stone blocks. This occurs at intervals of 5.5 block lengths, making the layout very clear.

- This relationship applies tan(6.6°) = 0.7 / (5.5 ⋅ 1.1) = 0.116

- Archaeological evidence shows that ramps near the Great Pyramid had a slope of around 7 degrees.

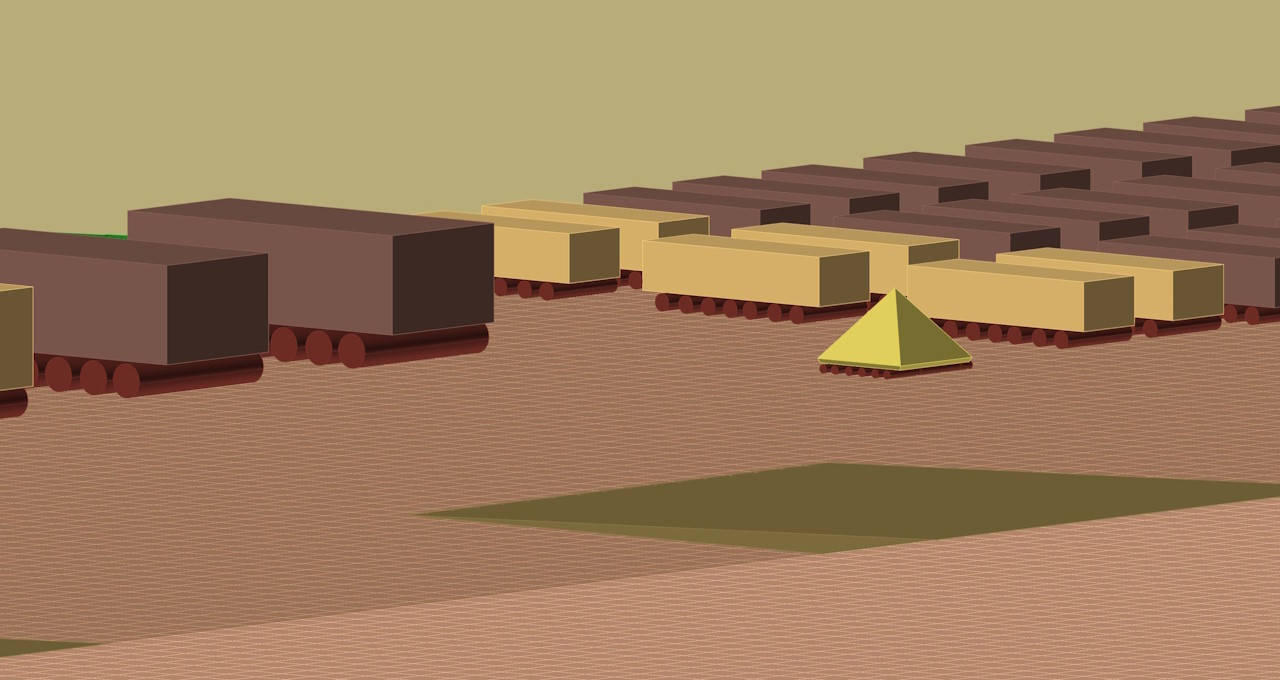

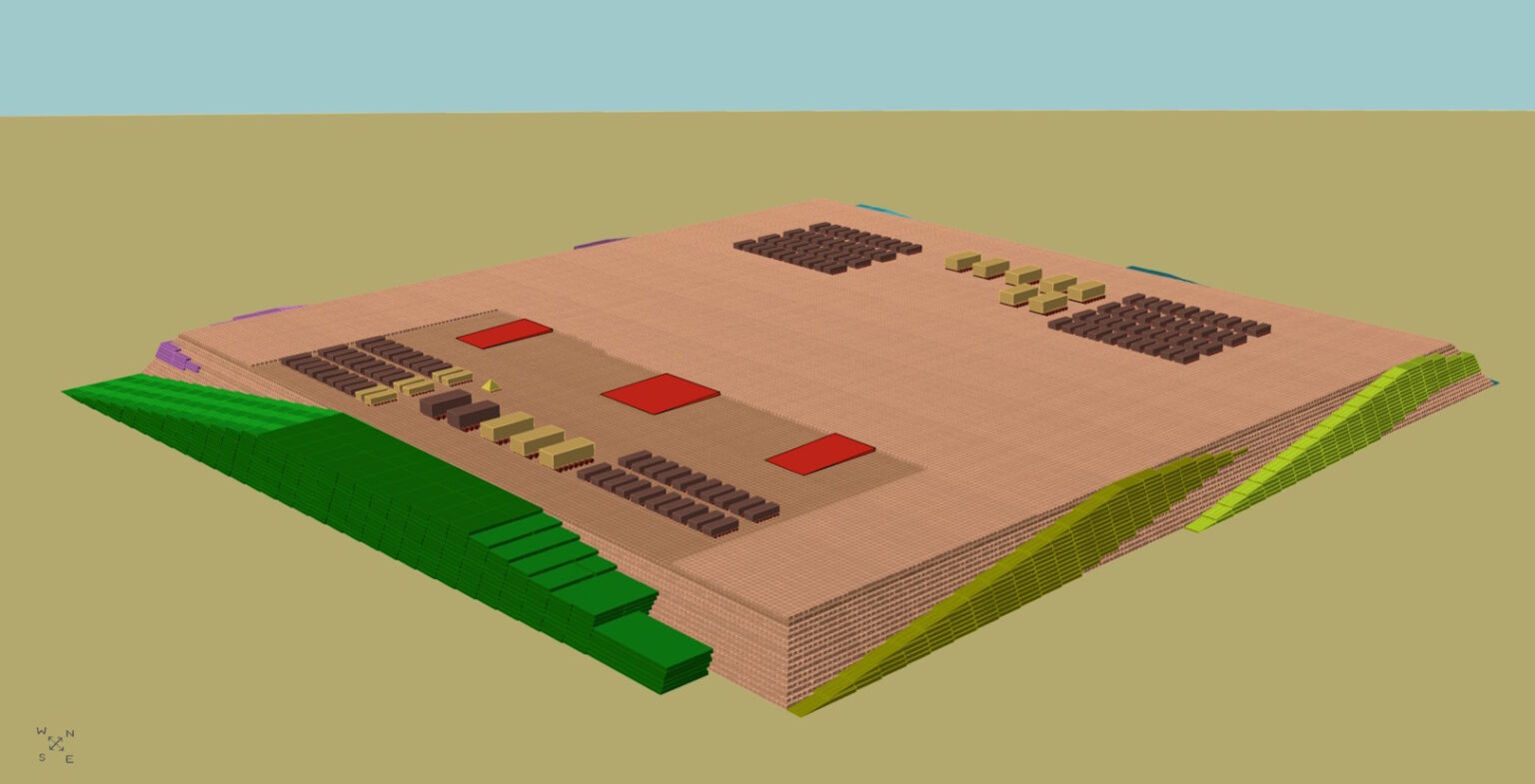

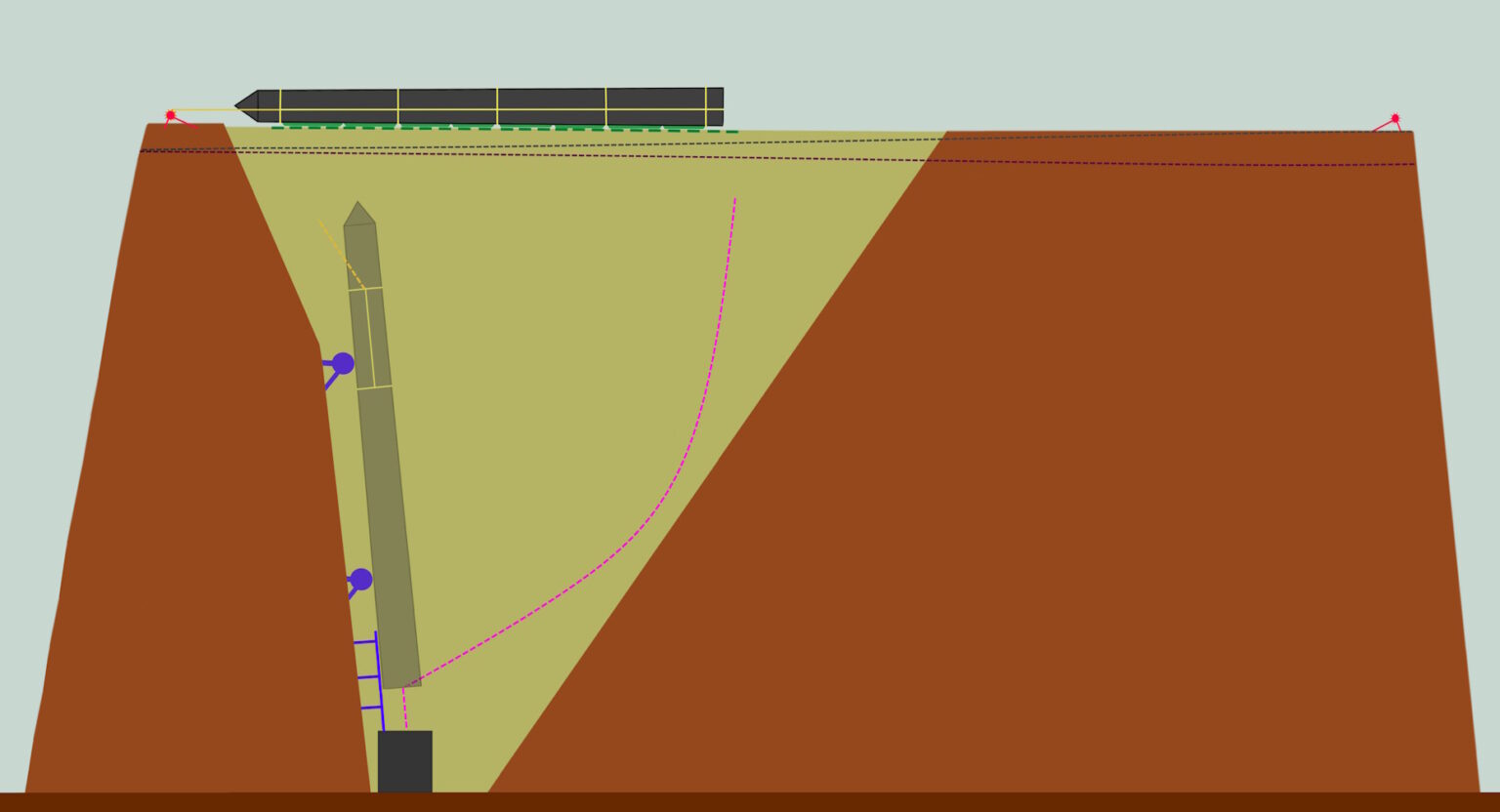

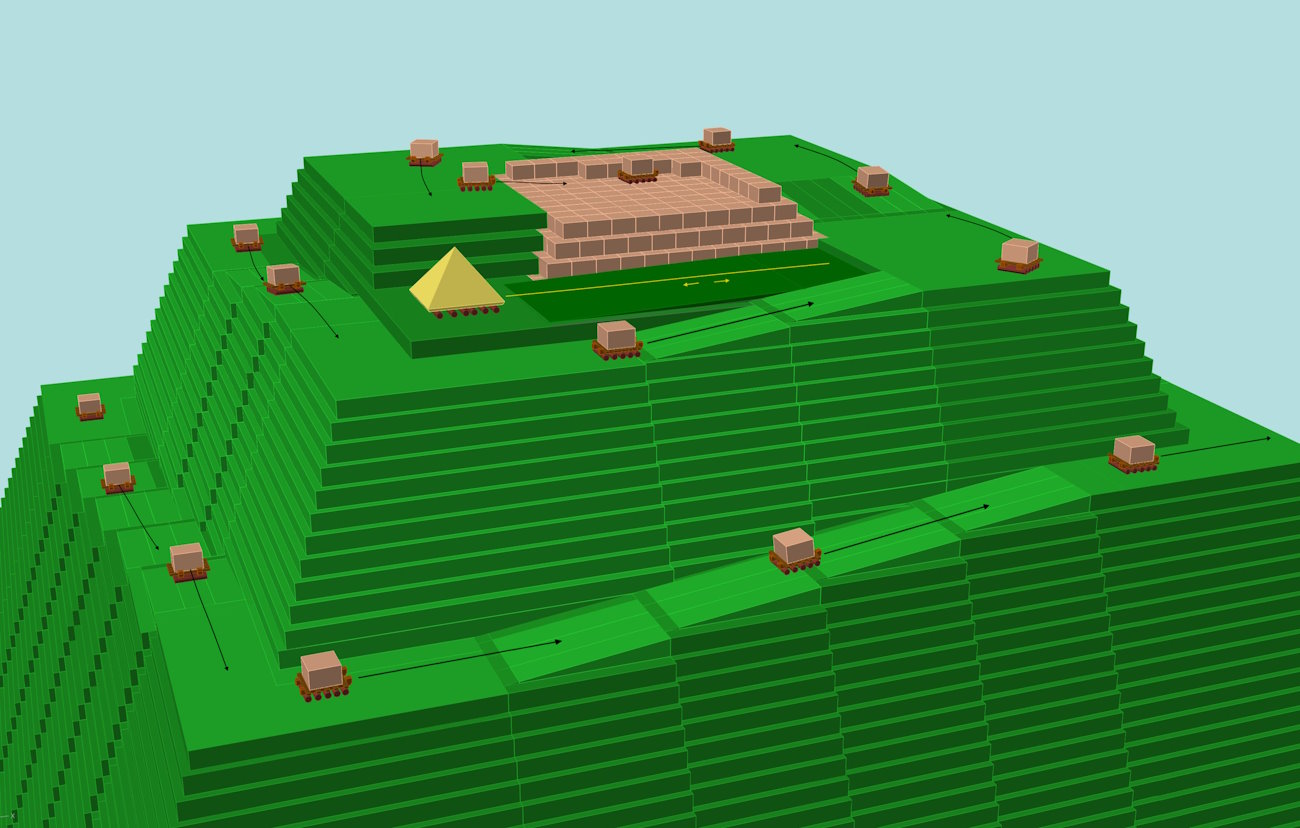

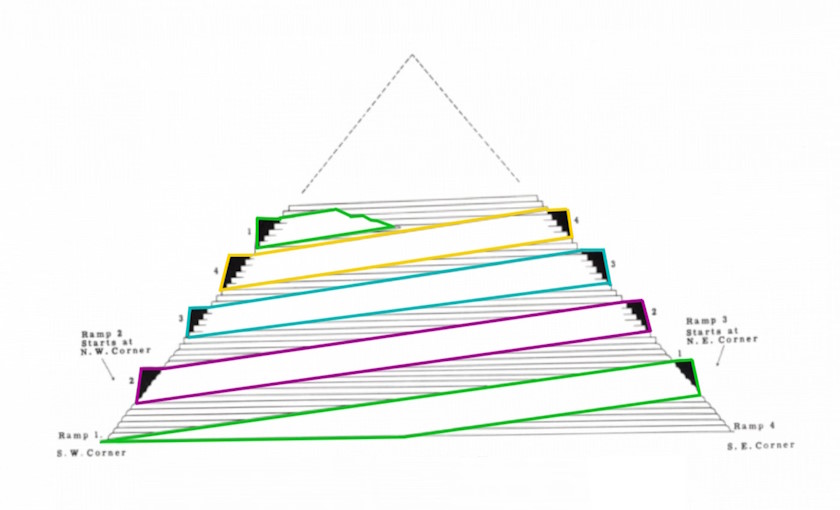

Multispiral Model

The main green path begins on the south side, about 400 m from the quarries, from where 99 % of the material is delivered. See the image of the Giza Plateau.

The main ramp leads to the top of the pyramid. In the upper third of the pyramid, the ramp paths partially rest on the path below. This creates a working platform at the top of the pyramid, allowing the pyramidion to be placed on top. See the Pyramidion section.

When transporting a block from the bottom to the top, a distance of 1.8 km is covered and 7.5 circuits are made. The transport takes 8.8 hours. The values are given in detail per level in Table 3.

On the other 3 sides there start 2 ramps with only one transport lane.

These 6 single paths end at different heights. The ends are marked in red.

The entire model consists of 7 spiral paths.

The dark blue ramp ends at the north entrance which is marked in black. This was a restricted access area.

- The green main ramp has 6 lanes in the initial phase. The outer 3 lanes are marked by orange lines. After the first turn of the ramp after 5 years, the outer 3 lanes can be dismantled and the ramp material can be reused further up. Compare the images Construction Time and Huge Blocks.

- The dynamic ramp construction is carried out in 3 steps, whereby 40 % of the ramp material is recycled or saved.

- The total ramp material has a volume of only 6 % of the volume of the pyramid. This is a huge advantage over the external ramp, which has a volume of 160 %. The values are given in detail per level in Table 3.

- The many ramp paths make it possible to create a working platform at any location for the later application of the outer casing. See the Casing image.

Towing Team

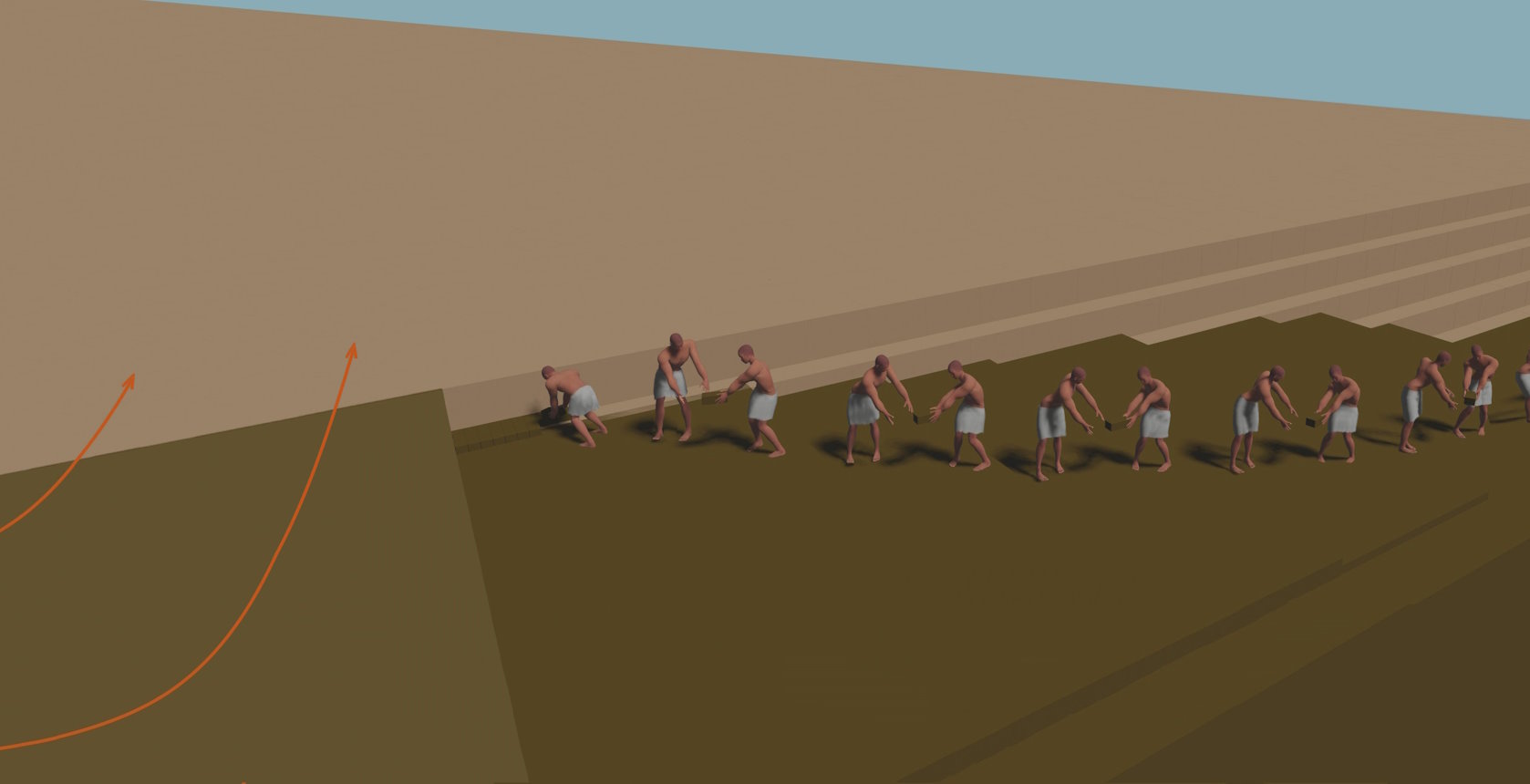

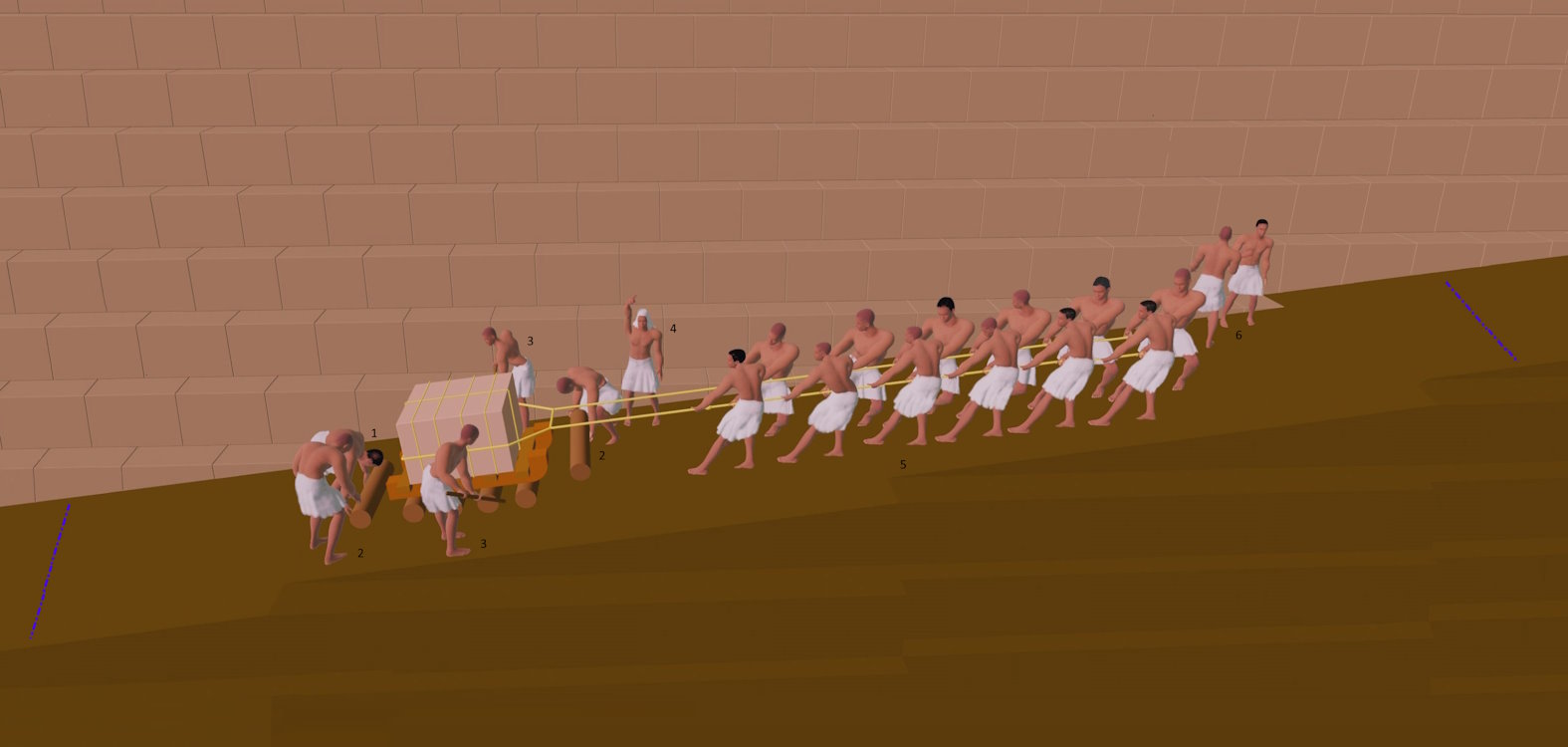

A towing team of 20 workers is required to transport a 2.3 ton block.

At the command of the commander (4), 12 workers (5) pull simultaneously for 1.3 seconds with a force of 23 kp. This moves the sledge with the block by 25 cm. During the pulling movement, the workers make the same sound.

The two workers (6) on the right are enjoying the break.

The two workers (3) with the wooden bares ensure that the rollers remain parallel and do not jam.

After the pulling movement, the sledge stands for 2.7 seconds while the towing workers (5) reposition themselves.

The two workers (3) clamp the wooden bars between the rollers, what prevents the sledge from rolling back.

The worker (1) on the far left must always stand behind the sledge and catch the rollers. This prevents the rolls from falling off the pyramid, which is a massive risk of accidents.

The two workers (2) transport the rollers from back to front and reposition them.

- Each transport lane has a width of 3 block lengths or 3.3 m.

- After a ramp length of 5.5 block lengths or 6 m, the height of one level or 0.7 m is reached.

- Within 4 seconds the team moves 25 cm, which corresponds to a speed of 3.75 m/min.

- The teams have a freedom of movement of 18.75 m. This is marked with the blue lines.

- One block can be delivered per lane every 5 minutes.

- Thus, 0.2 blocks are delivered per minute.

- This corresponds to 12 blocks per hour.

- For a working day of 12 hours per day in two shifts, this corresponds to 144 blocks per day and per lane.

- All teams must move at the same speed to avoid jams. See the Turning At Corners section.

- The workload of the workers over 6 hours with rotating breaks and relaxation on the way back can be compared to today’s working conditions and in no way corresponds to slave conditions.

- To ensure smooth transport with rollers, the surface of the ramps should be kept flat and stable.

In the literature, there are almost exclusively presented a transport method in which sledges were pulled over wooden beams. The beams were constantly lubricated with Nile mud to reduce friction. See the picture by Peter Jackson.

A towing team would consist of 25 workers and would be 5 workers larger than when transporting with wooden rollers due to the higher friction.

However, water carriers were required in addition when using Nile mud.

- The water carriers would have to deliver the Nile mud not only at the end of the delivery lane, but for all towing teams along the entire transport lane.

- When building the upper half of the pyramid, the routes are longer than 1 km and up to 80 teams would be on one transport lane. Therefore, the number of water carriers would increase considerably.

- The water carriers would require a separate walkway as they are large in number and would move at 4 times the speed of the towing teams. This way is marked by the two blue lines. Therefore, the ramps would need to be 20 % wider. This would increase the ramp volume by 44 %. The same applies to the number of workers for ramp construction.

- For example, let’s look at level 112, where 90 % of the volume was built up. At this point, an additional 1,747 water carriers would be required, which are missing for other tasks, as shown in Table 4. In this case, the number of blocks installed per day would be 279, whereas the corresponding number for the transport method using wooden rollers is 380.

- In addition, the workers would have difficulty moving on the slippery transport paths.

- Under the same working conditions, it can be said that with this transport technique, the construction time would increase by 6 years and the total work by 33 %. The detailed values and comparison are shown in the appendix of Table 4.

- The greatest possible efficiency was required at every stage of the process, because the project was a fight against time.

Construction Time

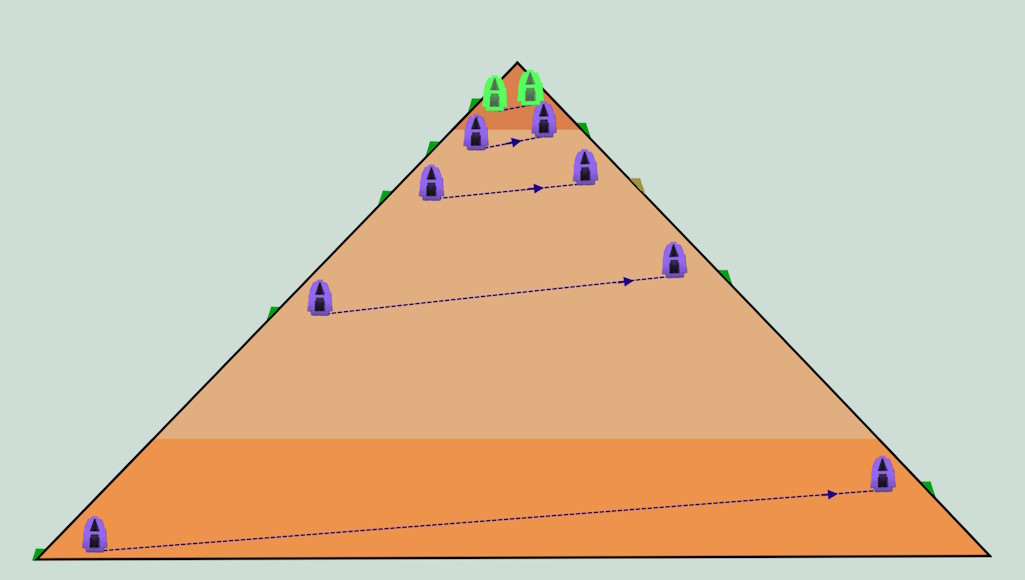

The image shows level 112, where 90 % of the material has been installed.

At this stage, the main green path has only 3 lanes in the lower section. The ramp material from the remaining lanes has been transported upwards for dynamic reuse.

There are also the light blue and dark purple paths, each with one lane. In total, there are 5 lanes leading to level 112.

One of the 5 transport lanes was used exclusively for the way back. This enabled a circular movement without collisions.

This leaves 4 lanes for the delivery of the blocks.

- Level 112 has a width of 210 – 112 = 98 block widths.

- Therefore, this level consists of 98 ⋅ 98 = 9,604 blocks.

- There can be 144 blocks delivered per day and per transport lane.

This requires 6 ⋅ 144 = 864 workers in the quarries. - At full capacity, there are 54 towing teams on one lane.

This requires 2 ⋅ 20 ⋅ 54 = 2,160 workers per day over 2 shifts.

The exact method of calculating the number of workers is shown in Table 1. - The productive workforce is calculated as 864 + 2,160 = 3,024 workers.

This represents 66 % of the workforce. - A total of 3,024 ⋅ 100 / 66 = 4,582 workers were needed to operate one delivery lane.

- During the three-month Nile flood, the maximum number of 20,000 workers was available.

Therefore, 20,000 / 4,582 = 4.36 lanes could have been operated. - In the upper half of the pyramid, the maximum number of workers could no longer be utilized because space became increasingly limited as one ascended. Physically, only 4 delivery lanes were available.

This allowed for the delivery of 4 ⋅ 144 = 576 blocks per day. - In the remaining 9 months outside of the Nile flood, there were only 10,000 workers.

Therefore, 10,000 / 4,582 = 2.18 lanes could be operated during this time.

This allowed for the delivery of 2.18 ⋅ 144 = 314 blocks per day. - This results in an annual average of 380 blocks per working day, using 2.64 transport lanes.

- Therefore, this level has a construction time of 9,604 / 380 = 25.3 working days.

- Since there were 300 working days per year, this corresponds to 25,3 / 300 = 0.084 years or approximately one month.

- In this way, the values for all 210 levels can be determined. Adding the values up to level 112 results in a construction time of 14.8 years at this point. See the Overview Image.

- By adding the values for all 210 levels results in the construction time of 18.4 years for the inner step pyramid. Detailed values are shown in Table 2.

- This leaves 1.6 years of the total construction time of 20 years. This is enough time to install the outer casing, remove the ramps, and construct the perimeter wall. See the Outer Casing section.

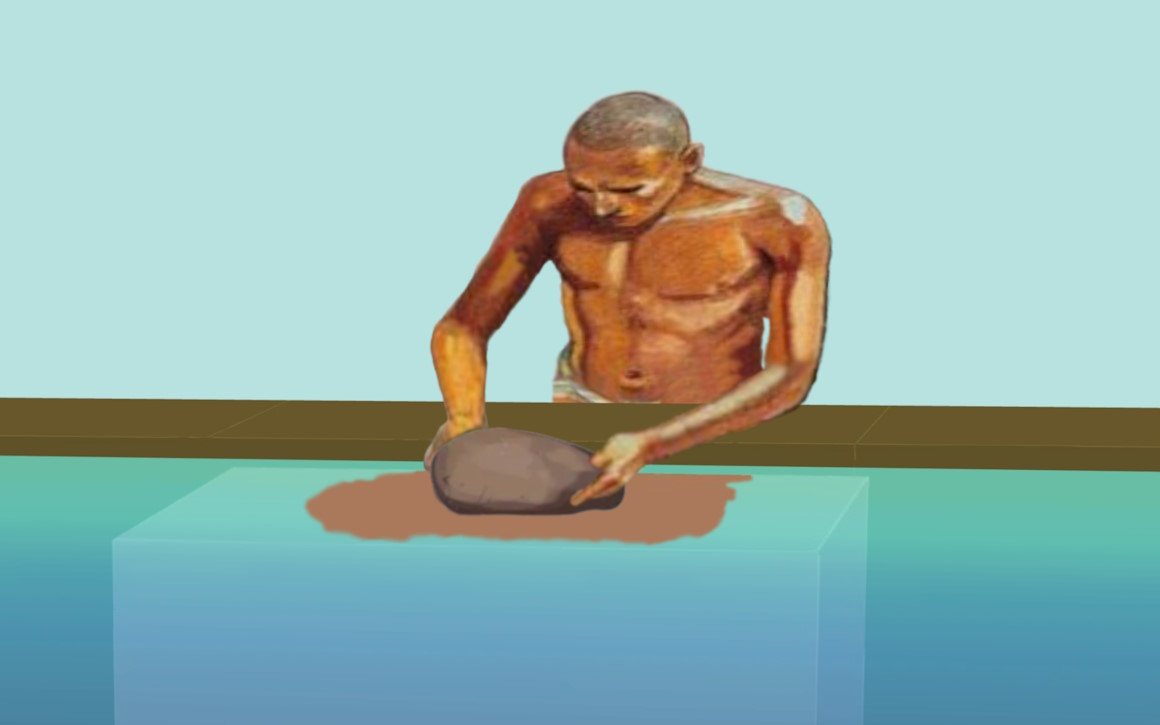

- The outer casing requires only 0.7 % of the material, but must be polished smooth. See the Precision Work image.

- Table 1 gives a condensed overview of how the number of transport lanes decreases with increasing height of the pyramid, but the number of workers for towing increases.

- Table 2 shows how, with increasing height, the individual levels have fewer blocks. Overall, the construction times for the different levels decrease slightly with increasing height.

- Table 3 contains some key figures, e.g. the „number of blocks per minute“ which has a value of 1.4 at the lowest level and 0.2 at the highest level.

- In the literature, a single tow team is usually used as the starting point for the calculation. However, this is problematic because the quantity delivered depends heavily on the height of the pyramid. Furthermore, the number of workers required for towing, production, and overhead are linked.

Therefore, an entire delivery lane must be considered the smallest unit of calculation. We can view a delivery lane as an assembly line in a modern company, which gets longer and longer as the pyramid gets taller.

The number of delivery lanes is a measure of the overall system’s performance factor. - This model proves that the system of spiral ramps has sufficient transport capacity in the upper range of the pyramid. This is in contradiction to the literature. There are only models used that have only one transport lane in the upper two thirds of the pyramid. In this case the construction period would be at least 30 years.

- The transport problem can be completely solved with the described system of ramps. No further technology is necessary. This is contrary to the literature where it is mentioned that ramps require supplementary devices.

The diagram shows the different construction phases if the pyramid is divided into three equal parts according to height.

At the end of the first third, it can be seen that after 10 years, one third of the height was reached and 70 % of the volume was built.

It’s clearly visible that an average of 2.7 transport lanes are used in the middle third. If only one lane were available here, this construction phase alone would take more than 18 years. See the Internal Ramp section.

After 18.4 years, the inner step pyramid was constructed. Then the outer casing was installed from top to bottom in 1.6 years, so that the construction was completed after 20 years.

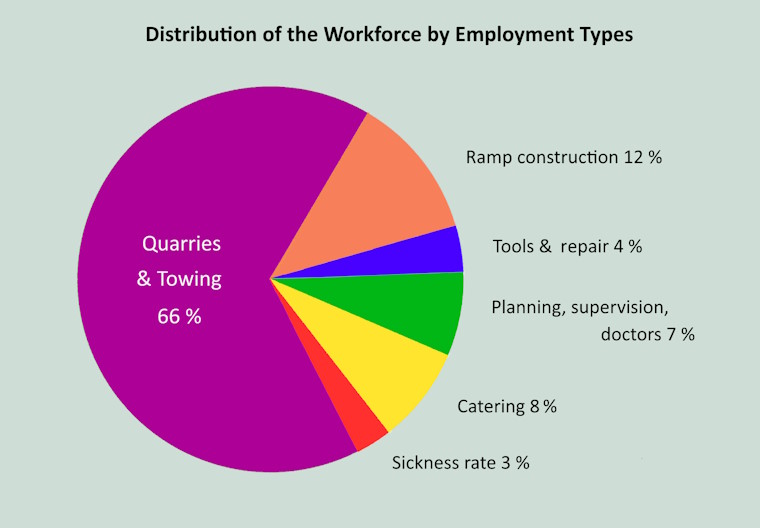

Workforce

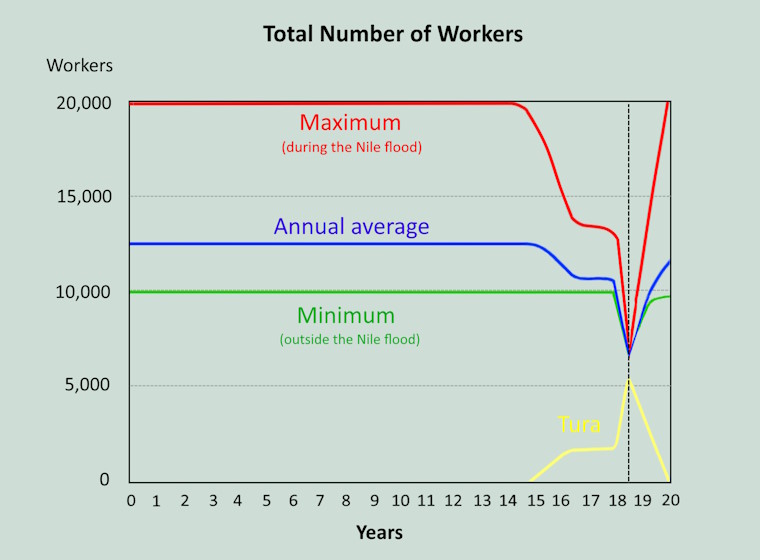

During the Nile flood, 20,000 workers were employed at the pyramid over 3 months. This is shown by the red curve (Maximum).

During the remaining 9 months there were 10,000 workers. This is shown by the green curve (Minimum).

On average, there were about 12,000 workers, which is shown by the blue curve (Annual average).

After 14.2 years, half the height of the pyramid was reached. Since space in the upper area became increasingly limited, fewer and fewer workers could be used.

Therefore, the remaining workers were employed in the quarries in Tura. The blocks of white limestone for the outer casing were obtained there. The yellow curve represents the annual average number of workers in Tura.

The productive portion of the workforce was 66 %. They were either employed in the quarries or towing stone blocks.

In the initial phase, production in the quarries was high and transport distances were short. The ratio of quarry and towing workers was 7 to 3.

As the pyramid increased in height, production decreased, transport distances increased, and the ratio changed to 2 to 8. The details are shown in Table 3.

„Other workers“ comprised 34 % of the workforce and were broken down as follows:

– Construction and maintenance of ramps 12 %

– Sledges, tools, repairs 4 %

– Planning, supervision, doctors, priests 7 %

– Food preparation, beverage service 8 %

– Sick leave, injured 3 %.

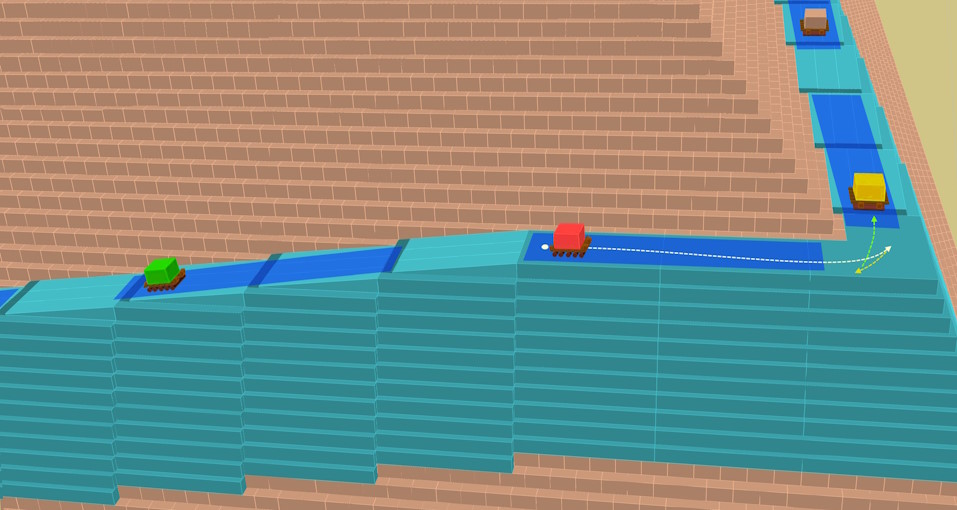

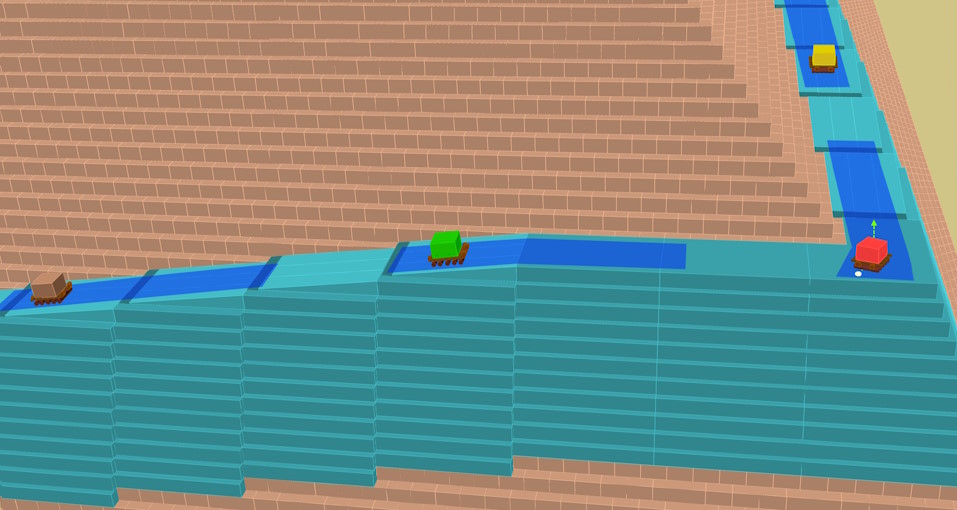

Turning At Corners

For decades, spiral ramps have been criticized that turning the blocks at corners is extremely difficult and time-consuming, leading to queuing. But how can this be avoided?

The distance between the green and red blocks is 18.75 m. At a transport speed of 3.75 m/min, this takes 5 minutes. The space required by the towing teams is 12.75 m long and is shown in bright blue.

Over the next 5 minutes, the red block must be moved into the position of the yellow block. To do this, the red block must be moved so that the white dot behind it moves along the dashed lines. This process is comparable to parking a car.

Since the yellow lane runs backwards, the required path is longer and transport across all 3 lines would take 6.3 minutes.

To compensate for the 1.3 minute time loss, the towing team moves along the white lane at 1.5 times the speed. This is easily feasible because the ramps in this area have no gradient, requiring less than 10 % of the usual towing force. Therefore, moving through the white lane takes only 2.7 instead of 4 minutes.

The image shows the position of the red block after 3.8 minutes. This is at the end of the yellow lane, which takes 1.1 minutes to complete. Although this is the critical point, the 6 m buffer zone does not decrease.

The green lane requires 1.2 minutes. Therefore, all 3 lanes take 5 minutes, which is the desired time for the turning maneuver.

Thanks to the logistical ingenuity of the ramps having no incline at the corners, the speed can be increased in a specific zone, saving 1.3 minutes.

Otherwise, the buffer zone between the green and red blocks would be reduced from 6 m to 1 m. This would cause the two towing teams to run into each other in close proximity. So there is a constant risk of waiting and queuing. Any time loss would also be passed on to all subsequent towing teams. This would mean that the cycle time for delivering the blocks could not be met, and the construction time for the pyramid would be increased.

When turning at corners, the sledge must be moved along several curved paths. The rollers are placed only halfway under the sledge, so that only one runner of the sledge rests on each roller at a time. This allows the rollers on both sides of the sledge to rotate independently of each other, preventing them from interfering with each other due to uneven movement. This is similar to the way a car moves around a curve.

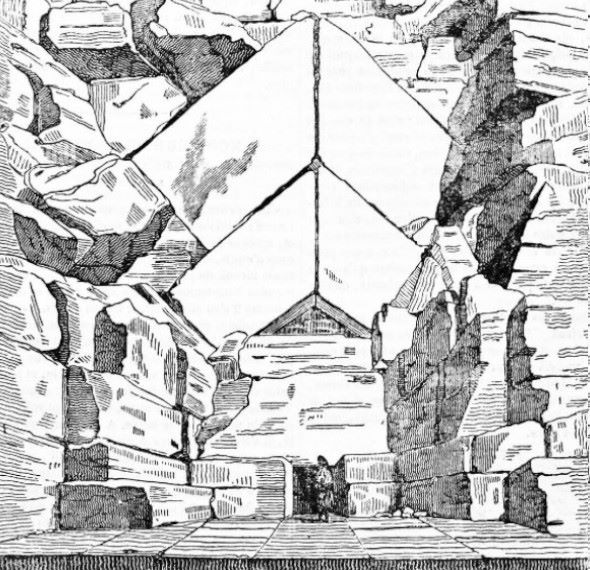

North Entrance

The image shows the north entrance, which is offset 7.29 m from the center line to the east.

The reason for this is probably the pyramid’s 8 sides, as the highest compressive loads occur along the bend line. See the Eight Sides section.

Limestone blocks weighing up to 70 tons were used for the roof. Until now, there has been no suggestion as to how the roof blocks could be positioned without scratching them.

The two blocks were aligned horizontally to the height of the dashed line (green). Then the blocks were tied together at the bosses (purple).

The sand was then removed from the outer ends, causing the blocks to sit like a saddle over the pile of sand.

By further draining sand, the blocks landed on the safety rails (brown) and took up the dashed position (blue).

Then the remaining sand and the catching rails were removed and the bosses were knocked off.

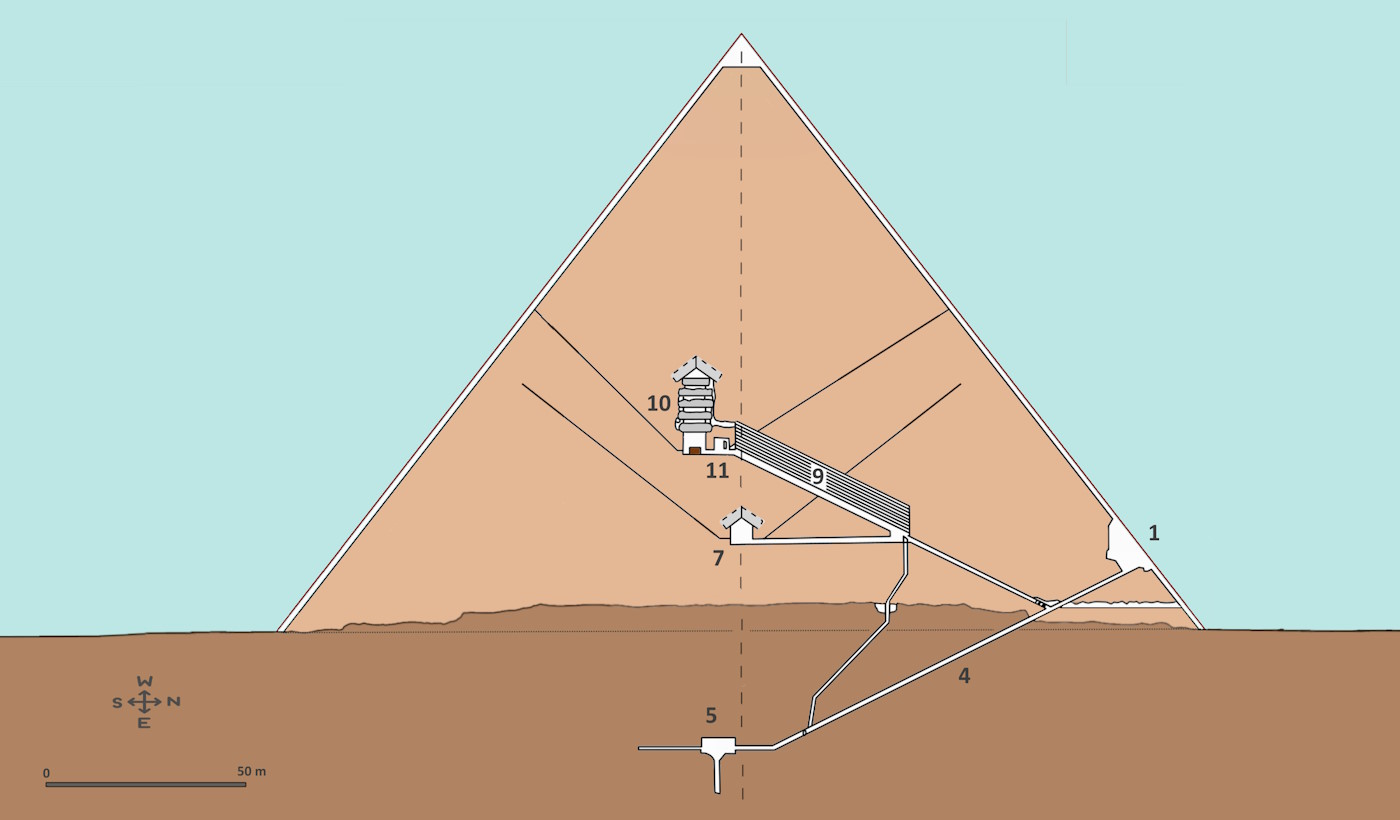

Huge Blocks

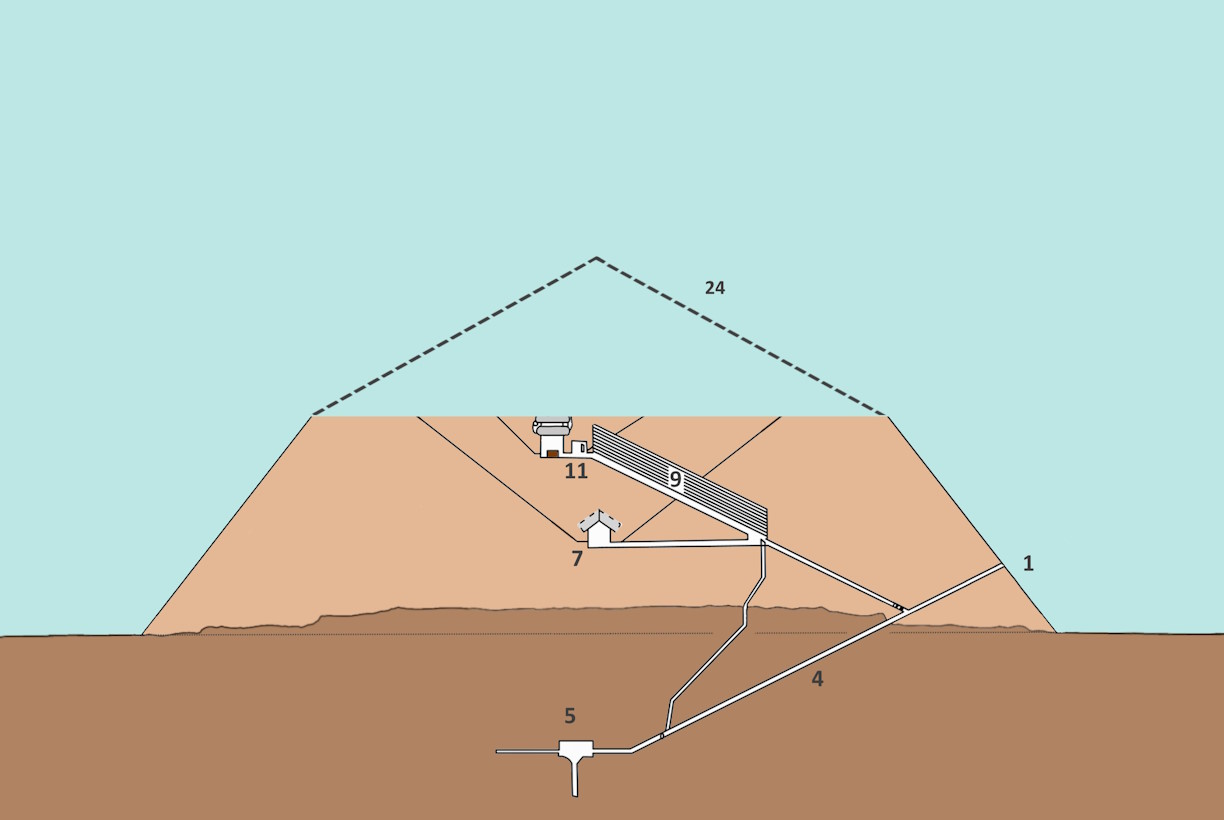

The image shows a cross section of the Great Pyramid.

Blocks of up to 70 tons were used for the roof of the King’s Chamber (10). Same for the roof of the Queen’s Chamber (7).

More than 100 granite blocks weighing up to 70 tons were used for the Great Gallery (9).

Huge granite stone blocks were used for the sacophagus chamber (11).

To the left of the image are blocks weighing 400 tons. There were a maximum of 12 of these.

To the right there are blocks that weigh 70 tons. There were around 130 of these.

The limestone blocks are shown in yellowish color and the granite blocks in purple color.

The pyramidion was probably placed on the pyramid at an early stage.

Zigzag Lifting

Spiral ramps are repeatedly criticized for not being able to transport the 70-ton blocks to the required height. Therefore, they are not considered a serious solution to the problem.

The multispiral ramp model uses a wide ramp (green) with a width of 9.9 m, which allows for the transport of large blocks. There is also a more elegant and efficient method.

During the first 5 years, the huge blocks were brought to the surface of the pyramid using the green ramp.

The huge blocks could then be transported upwards from level to level using temporary ramps (red) with a slight gradient of 2 degrees.

With this transport method, the huge blocks only had to be moved back and forth. There was no need to turn them at any corners.

The area on the pyramid was always so large that all the huge blocks never required more than 15 % of the area.

The image illustrates the method of the Zigzag Lifting.

On the left, there is a huge 70-ton block (black). It’s supported on wooden beams (purple) and was moved to this position using the temporary green ramp.

The green ramp was then removed and the dark blocks were installed. Then the temporary red ramp was built and the huge block was transported to the right side, lifting it one level.

Zigzag Lifting is the process of elevating a megalith by moving it back and forth on a growing building or hill.

In this process, the megalith lies on one half of the structure while the other half is built further upwards. Using a temporary ramp, the megalith is then towed onto the elevated side and thus lifted up a little bit. With a ramp angle of approximately 2 degrees, a towing force of only 10 % of the megalith’s own weight is required. By repeating this process many times, the megalith is gradually lifted upwards to the desired height as the structure grows.

This opens up a universal basic principle for prehistoric heavy-duty construction using minimal resources and clear construction stages:

– The method provides a complete and consistent explanation for the placement of heavy monoliths without machines or lifting booms.

– The technique is archaeologically neutral, based on comprehensible physical principles, and capable of reconstruction.

The Zigzag Lifting method can also be applied to the setting up of a 400-ton obelisk.

For this purpose, a hill of mud bricks is built. As construction progresses, the obelisk is transported upwards, following the dark dashed lines.

The middle section of the hill consists of sand (yellow). Through controlled removal of the sand, the obelisk on the right side moves downward (pink line). At the end of the sinking process, the obelisk (light line) is located on the catching rails (blue).

By sliding down the catching rails, the obelisk positions itself precisely on the base and then stands upright.

The Zigzag Lifting method can also be applied to the erection of the standing columns at Stonehenge (UK).

The megalith (black) is lifted upwards by moving back and forth along the yellow and purple lines.

Then the earth of the hill is removed in a controlled manner, with the column (grey) being lowered and erected in a controlled manner via the catching rails (light green).

When positioning the crossbeams (lintels), the columns are inside the hill and the lintel is pushed across the columns.

Furthermore, the Zigzag Lifting method can also be applied to other megalithic scenarios:

– Easter Island (Rapa Nui): Erecting the Moai figures on platforms (ahu)

– Dolmen structures in Europe and Korea: Placing heavy cover plates on standing stones

– Malta (Mnajdra, Ħaġar Qim): Moving huge limestone blocks in temple construction.

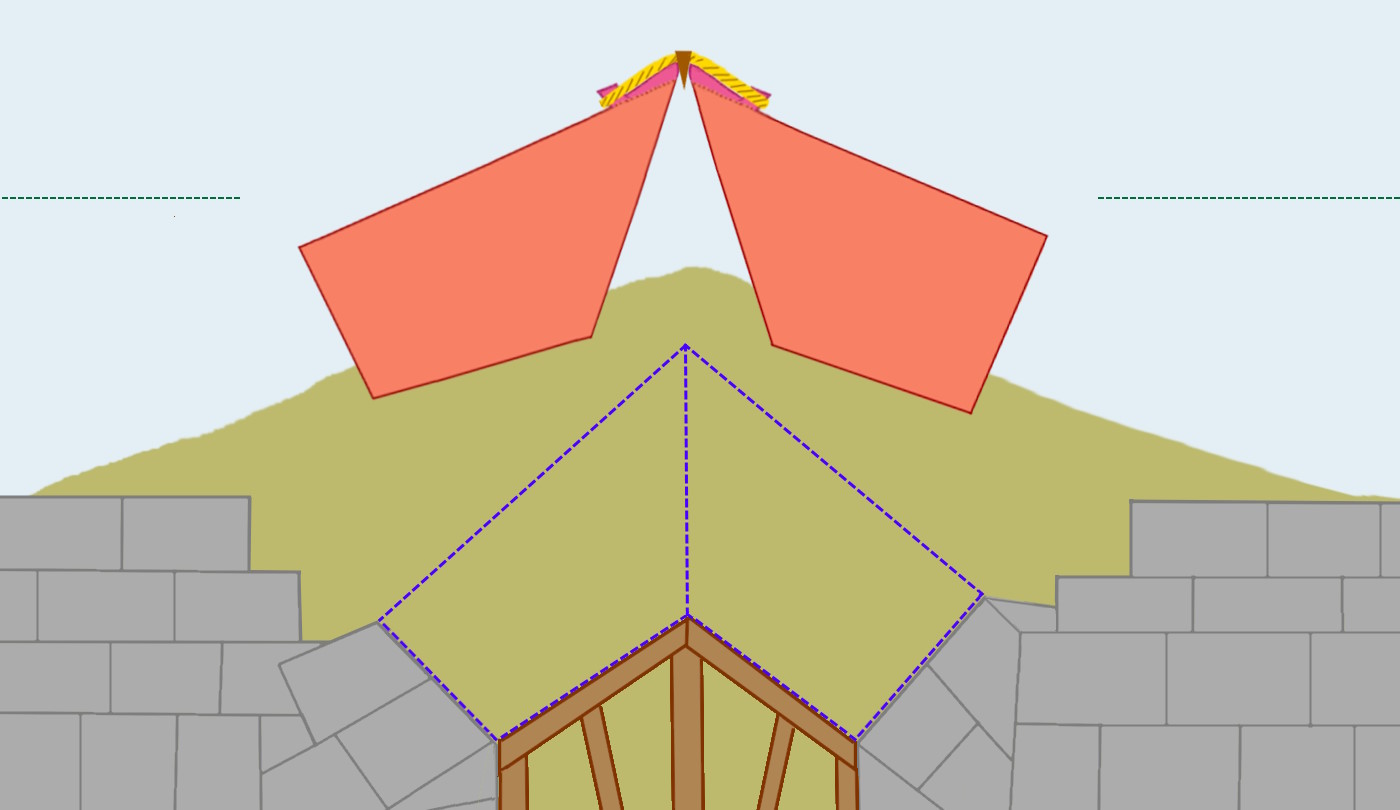

Pyramidion

In the top third of the pyramid, the green main path is partially positioned on the lower circuit. The path therefore becomes narrower on the lower circuit and only has the capacity of one transport lane.

The pyramidion is 3.3 m wide and weighs 20 tons. Since the area in the upper area of the pyramid is becoming increasingly limited, the pyramidion must be placed on the ramps.

The pyramidion is moved back and forth according to the yellow line. The ramp is increased with a ramp wedge of 2 degrees with each movement. In this way the pyramidion is transported upwards without having to be turned. This method is called zigzag-lifting.

The pyramidion is transported on wooden rollers and rolled onto the top platform.

Then the pyramidion is lifted with wedges and the rollers are removed. Using additional wedges it is lowered and placed precisely.

The pointed edge lines in the lower area of the pyramidion were separated. Otherwise the outer edges would break off due to the enormous pressure from the wedges. This is consistent with the historical findings.

The placement of the pyramidion was considered as the completion of the pyramid and the success of the project.

This was celebrated as a topping-out ceremony and a major state act. For this purpose, the Pharaoh and his wife were carried upstairs on the palanquin. The top of the pyramid was packed with all the important people of the state.

On the left is the chief designer Hemiunu, who is celebrated as the hero of the day. The high priest stands in the back and looks jealous.

The wrapping of the ramps created a platform that was covered with a red carpet for the ceremony.

- With this transport technology, setting up a pyramidion with a width of 3.3 m and a weight of 20 tons is completely unproblematic.

- Even a pyramidion with a base of 4.4 m and a weight of 75 tons could be placed using this construction technique.

- From an archaeological point of view, there are no finds of the pyramidion of the Cheops pyramid. It was probably smaller than 2 m at the base and weighed less than 7 tons, as the finds at other pyramids show.

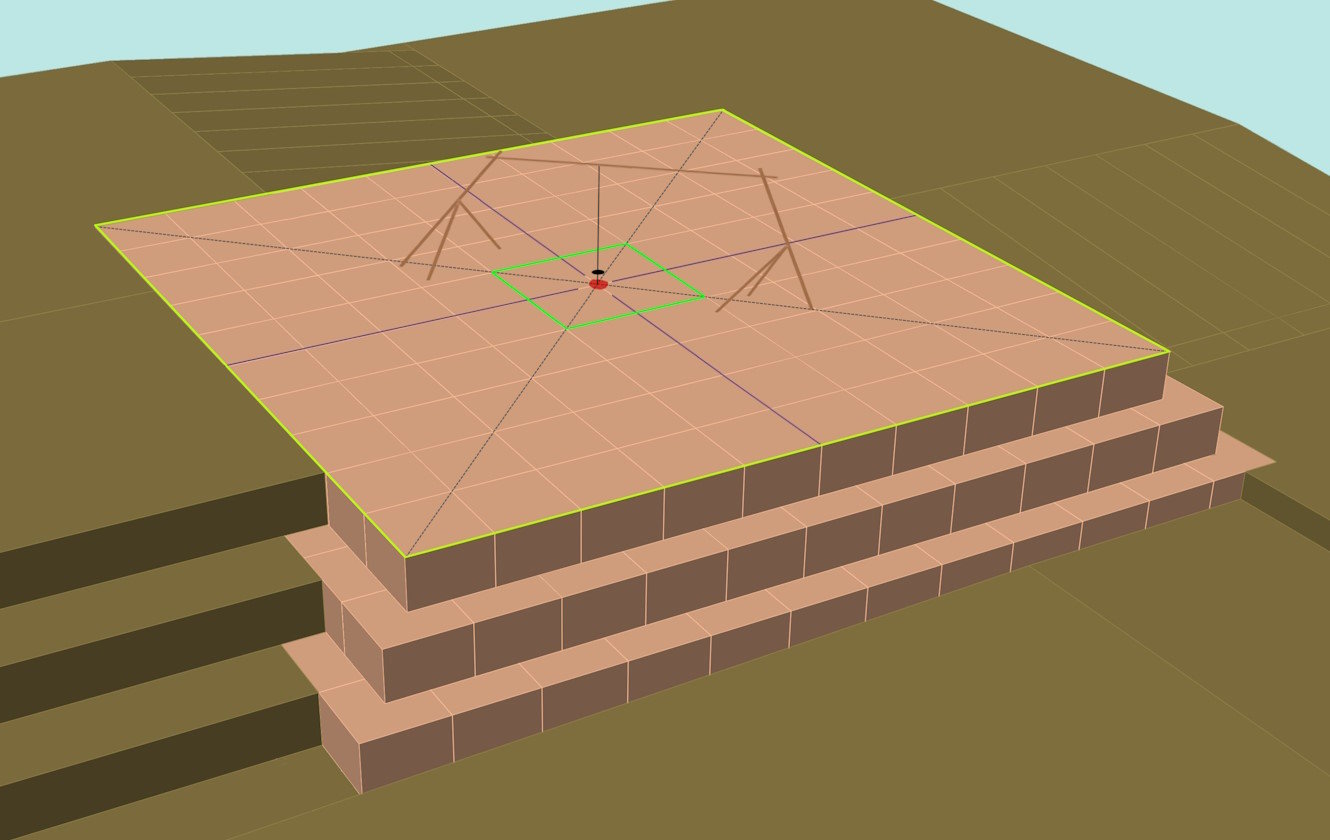

Outer Casing

The many ramp paths make it possible to create a work platform on each level at any point.

If this is not possible in some places, a work platform can be created using material that was removed further up.This is dynamic reuse of work materials. The relevant areas are indicated by yellow lines.

A direct view to the top of the pyramid is possible at any point. The casing can be sanded with millimeter precision, which results in the high precision of the structure. See the Measurements and Precision section

At the end of the top-down process there was a shiny white pyramid in a geometric classic style.

This process took 1.6 years. Only 0.7 % of material was required based on the pyramid.

For the inner step pyramid, essentially only the pyramid apex needed to be precisely defined. The real precision came in attaching the casing.

Eight Sides

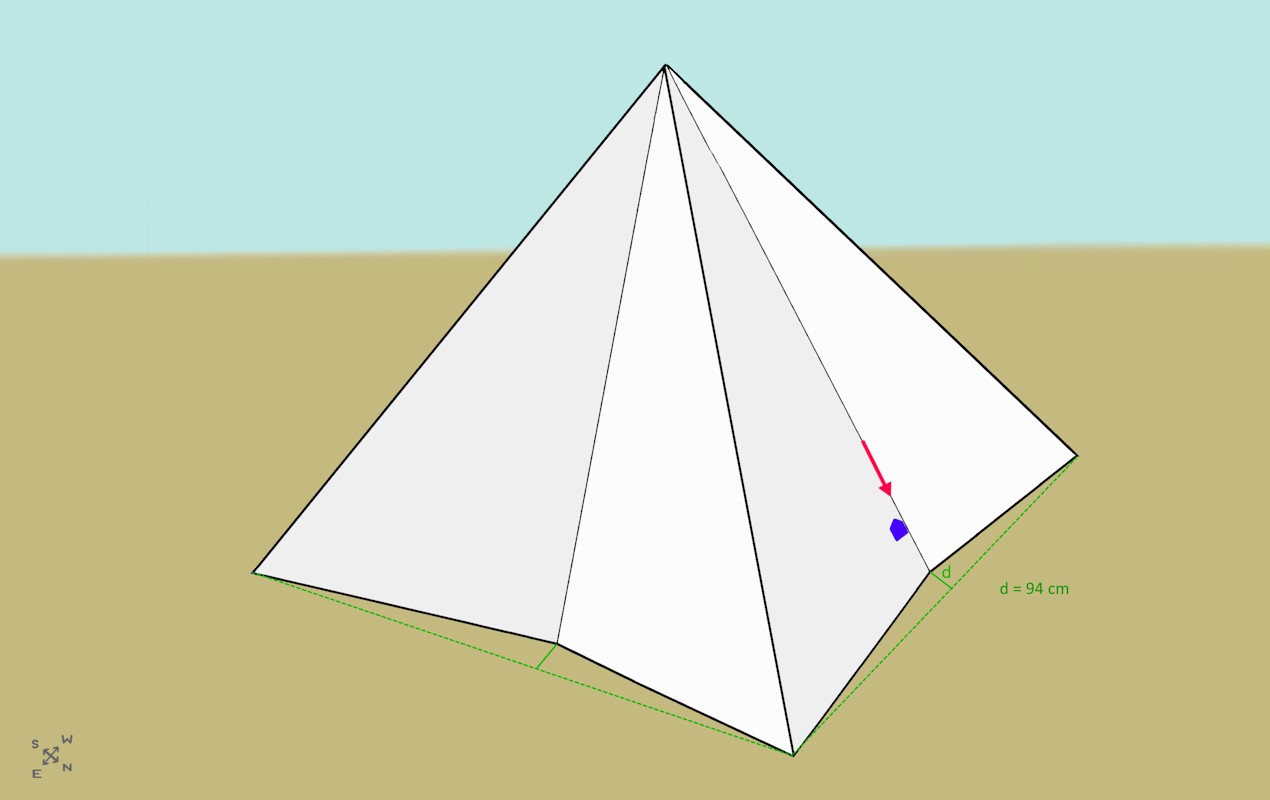

The side surfaces of the pyramid are curved inwards, so the pyramid is 8-sided. On the north side the inward curvature is 94 cm.

The reason often given for this is the greater stability, which behaves similarly to a piece of folded paper.

Since this principle was only applied to the Great Pyramid, other reasons appear to be at play here. These were probably of a symbolic or political-religious nature. See the Pyramid Height section.

The pressure is greatest along the central axis or the bend line (red arrow). Therefore, the north entrance (blue) is offset to the east. See the North Entrance section.

Magnitude

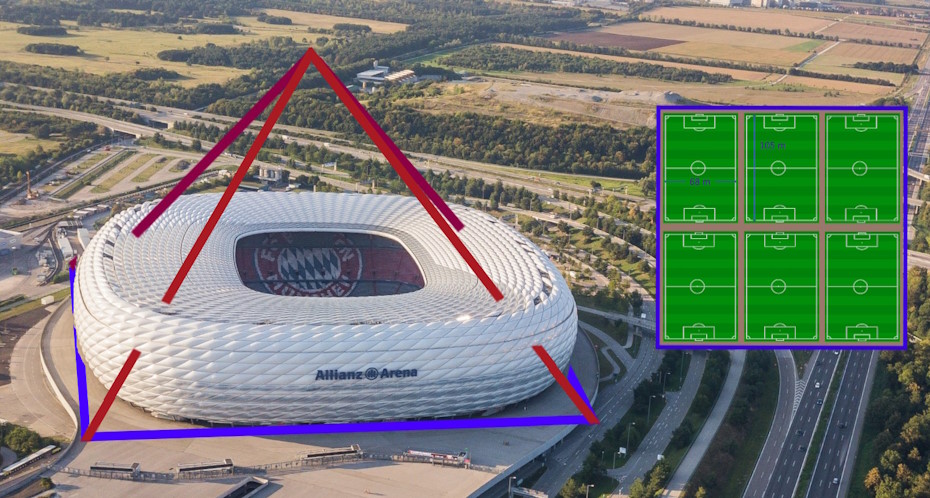

The Great Pyramid is 230 m wide, 146 m high and weighs almost 7 million tons.

The pyramid is so large that the narrow side of the Allianz Arena in Munich would fit in.

The area in the square marked in blue is so large that 6 soccer games could take place there at the same time.

Therefore, it is not surprising that the Great Pyramid was the tallest structure in the world for over 4000 years.

Real Pyramid

- In the previous considerations, a uniform pyramid was always assumed. The advantage is that this creates a measurement for a unit block. The calculations can be carried out more easily and clearly with the volume and weight of a unit block.

- The actual pyramid is not uniform. However, this makes no difference in the amount and positioning of the material used.

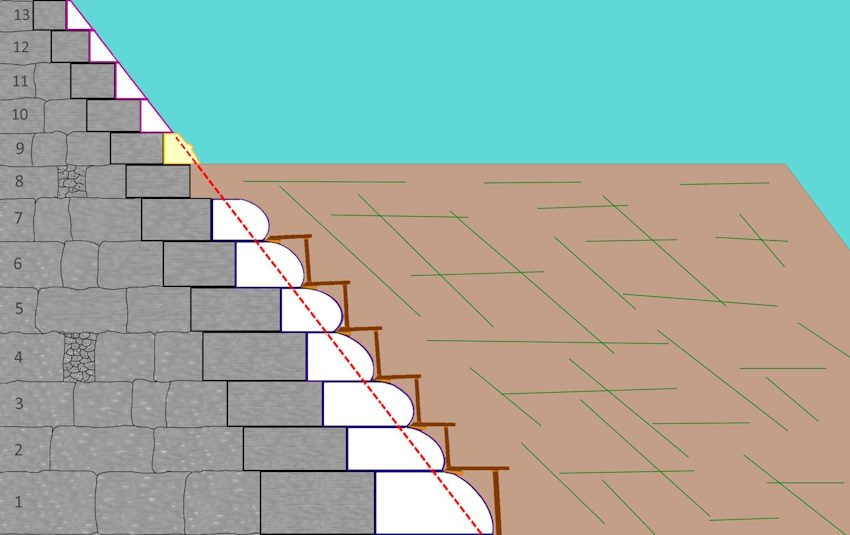

- The layer for the outer casing was very regular. This is shown in white in the picture below.

- The outermost layer of the inner step pyramid was regular. The blocks inside are completely irregular, which probably enabled the pyramid to survive several earthquakes.

- The lowest levels of the pyramid are much higher than the standard size, whereas the upper levels are lower.

The finds on the north side show that the blocks for the casing on the lowest level were very wide.

The blocks for the casing of the lower 10 m are shown in blue. These blocks could only be installed from bottom to top. Therefore, they were installed in parallel with the construction of the step pyramid.

For the lower 10 m, the ramps are mainly positioned on the ground. To provide additional stability to the ramps, wooden wedges (orange) were driven between the blocks and a wooden frame (brown) was attached to them.

Further up, the blocks for the outer casing are narrower. More than 80 % of their weight is positioned on the inner step pyramid. This is why these blocks (purple) could be installed from top to bottom.

- In the picture, the block marked in yellow is installed on level 9. The block has a bumpy front, which is also called a bossage. After installing the block, it is smoothed according to the red line. See the Measurements And Precision section.

- At the Pyramid of Menkaure there are finds on the lowest 7 levels of the unsmoothed granite casing.

- These finds probably inspired Georges Goyon to develop a model in which the entire pyramid is enveloped by the ramps and which was dominant for over 50 years.

Stability

- The Great Pyramid is the only well-preserved of the Seven Wonders of the Ancient World.

- It has resisted several serious earthquakes.

- One reason for this is the massive bedrock on which it was built.

- The casing was very regularly constructed. The same applies to the outer layers of the inner step pyramid. However, the core masonry is irregularly constructed and does not contain any continuous surfaces. This makes it difficult for cracks to propagate.

- There are probably rooms filled with gravel, which has a beneficial effect during earthquakes.

The outer casing in the upper region actually seems to have been the sensitive region in terms of stability.

The Pyramid of Khafre was built around 40 years later. Its outer casing is not attached in the uppermost region, but rather anchored to the step pyramid. The reason was probably rather against slight shifts due to temperature fluctuations than against damages by earthquakes.

This explains why the part of the outer casing is still there today. The mining was too strenuous even for the stone robbers in the Middle Ages.

This part of the outer casing had to be built from bottom to top along with the step pyramid. At this point, the ramps could not be installed on the step pyramid, but only on the lower circumference. However, this was technically possible.

Diodorus visited Egypt around 60 BC. According to his description, the casing was still in excellent condition, whereas a platform of 3.1 m had formed at the top of the pyramid.

Therefore we can say for sure that the pyramidion was not wider than 3.1 m.

The pyramidion was probably thrown off in the 217 BC earthquake or in an earlier earthquake.

The casing was originally made of white Tura limestone, which was almost completely removed in the Middle Ages.

Measurements And Precision

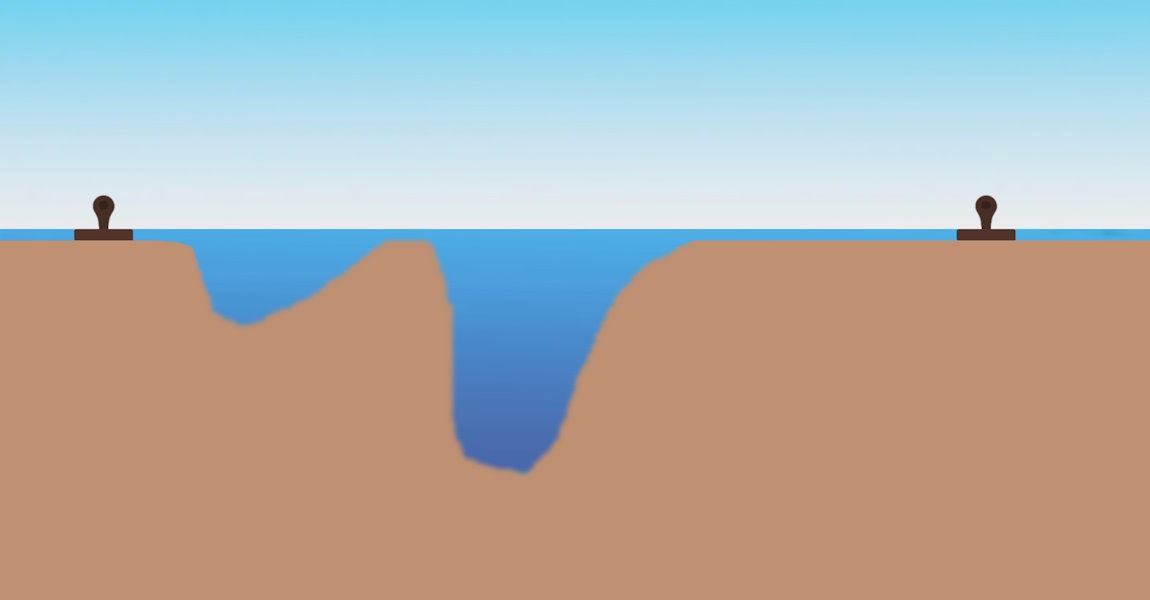

A connected pond has a perfectly planar surface.

To find out if two locations have the same height, can be determined by introducing two identical objects, e.g. stamps or coins.

The leveling or planar creation of a landscape can be done with this measurement technique. A distance of 250 m is no problem.

In the initial phase, the rock core was smoothed and a flat surface was created around it. For this purpose, an artificial pond was built using mud-bricks. Thus a planar surface could be created around the rock core.

A floating cord can be obtained, for example, when uniformly attaching bamboo tubes to a hemp cord. The cord is kept under tension by hanging stones at both ends.

Due to the tension and the mobility in the water, the cord constantly aligns itself or converges into the ideal position.

When taking several measurements at different times with the green measuring scale and then taking the average value, precise values in the millimeter range are obtained over a distance of 250 m.

When building by levels, measurements can be done at any time.

Plane surfaces and straight lines are obtained through artificial water ponds using mud-bricks.

The crucial thing is that the center moves exactly upwards. The best way to do this is to leave a shaft in the middle. This is shown in red color. A plumb is attached on a frame and is hanging down. This can be done in several steps and the individual shaft elements can be filled successively.

To further control the center point, the green square is moved up from one level to the other.

The actual precision work began after the pyramidion was put in place. Then the outer casing was attached.

This was done with millimeter precision. It was possible to look closely at the exterior surfaces from the side and upwards.

It was very important to maintain the angle. For this purpose, a special angle plumb with a length of several meters was made. There was a hanging pendulum on it, which was exactly between the red markings at the intended inclination angle of almost 52 degrees.

The precise length of the base in the millimeter range was determined late at the end of this process to be 230.33 m.

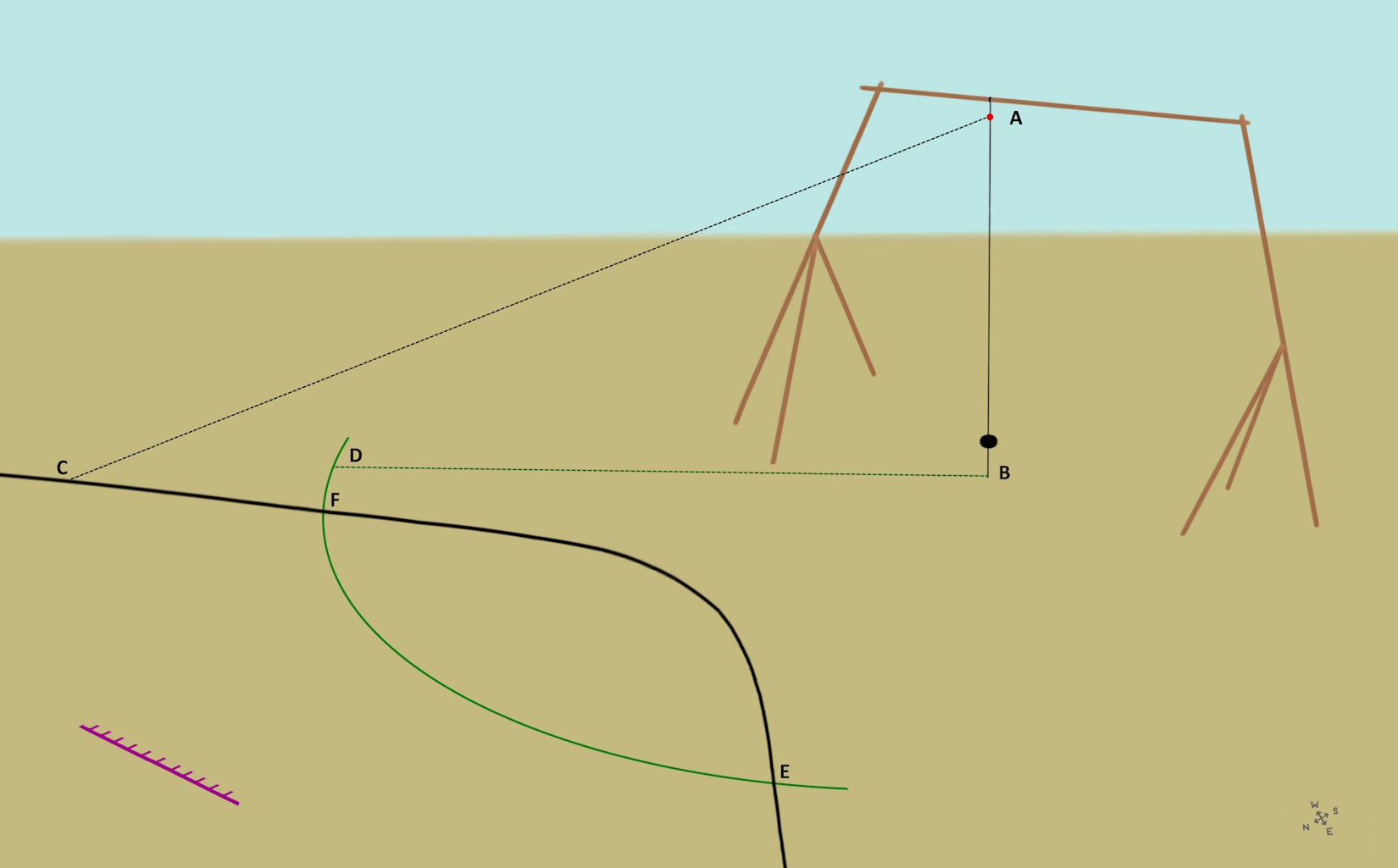

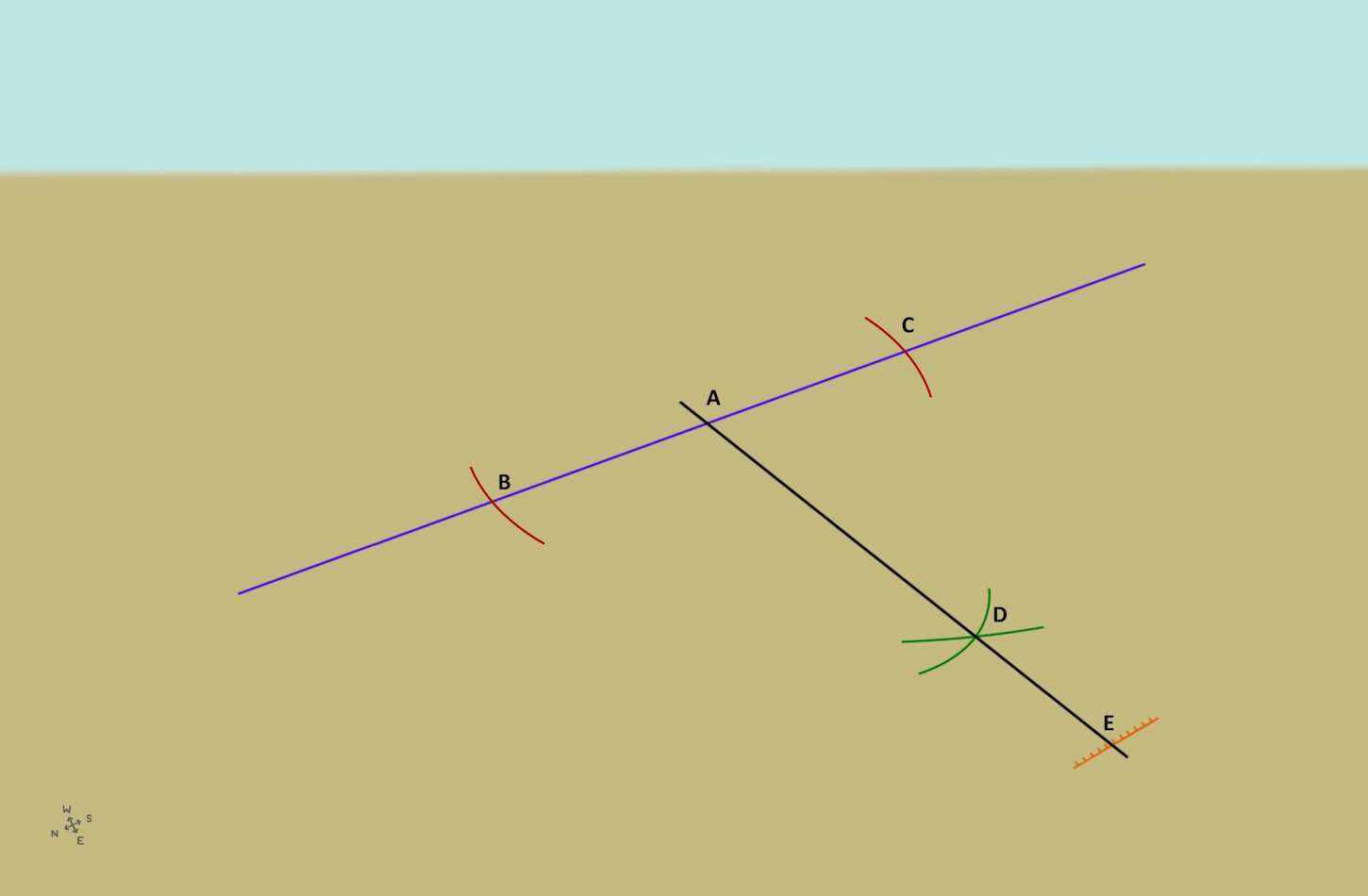

North-South Direction

The Cheops pyramid is aligned very precisely according to the four cardinal directions.

First the north-south direction must be precisely determined. To do this, use an approximately 5 m high plumb as a sundial. This is also known as a shadow pointer or gnomon.

At the lowest point of the gnomon B, the green circle segment with the radius to point D is drawn.

Point A casts a shadow on point C. This can be used to describe the black curve throughout the day. In the winter months the curve bends outwards.

The green and black curves have the two intersection points E and F.

Two red circle segments with the same radius are placed around these two points. These intersect at point G.

Then the blue line is placed through points B and G. This is the north-south direction.

The measuring point H is obtained on the purple measuring scale. Then the experiment is repeated for several days. When taking the average value, very precise values for the north-south direction are obtained.

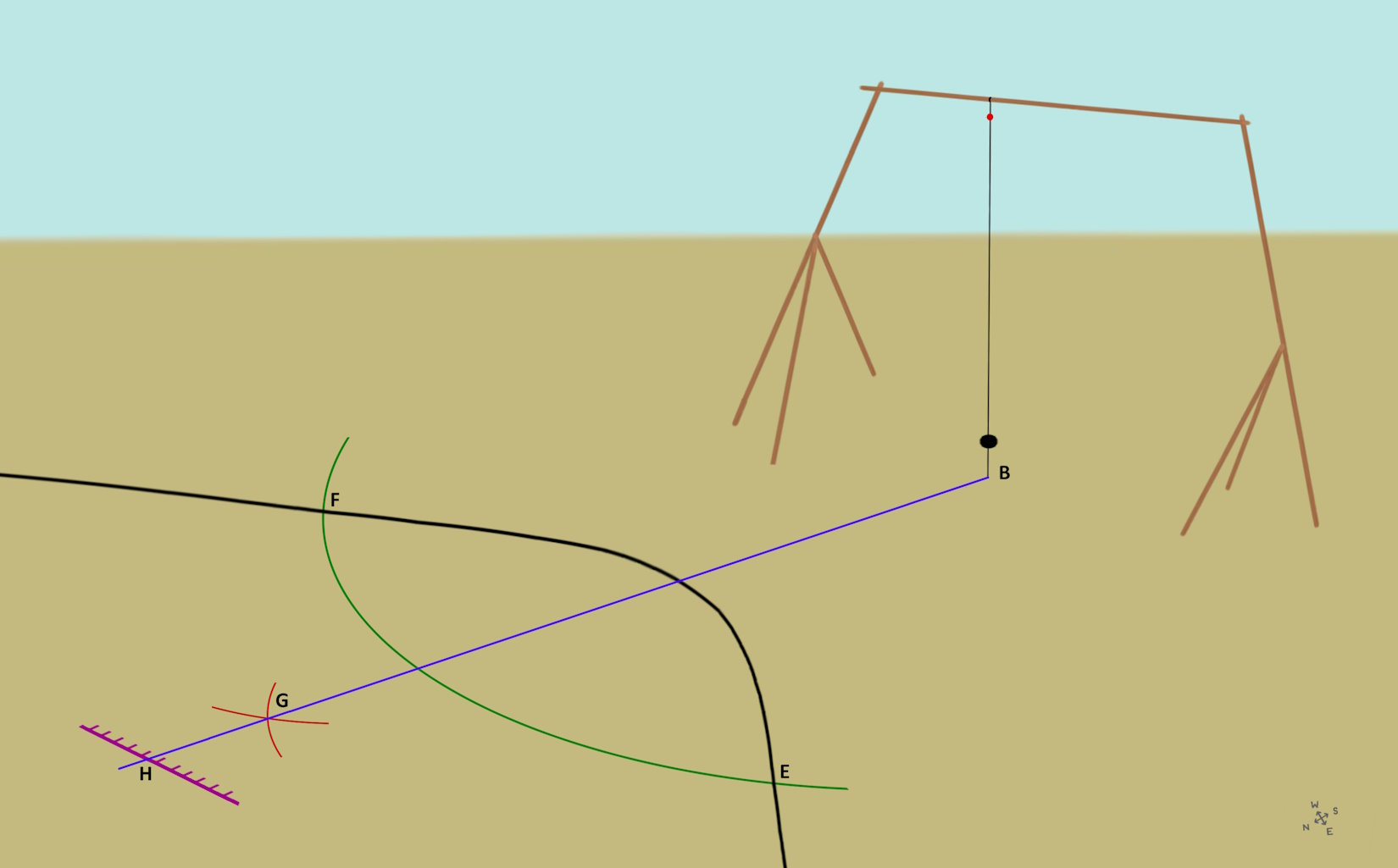

Now a vertical straight line should be generated in the east-west direction. The straight line should go through point A.

A red circle is drawn around the center point A. The circle forms the intersection points B and C with the blue straight line.

Two green circle segments with the same radius are placed around these two points. These intersect at point D. Then the black line is placed through points A and D. This is the east-west direction.

The measuring point E is obtained on the orange measuring scale. When repeating the experiment several times, the east-west direction can be determined very precisely. The Pythagorean theorem is not needed for this elementary method.

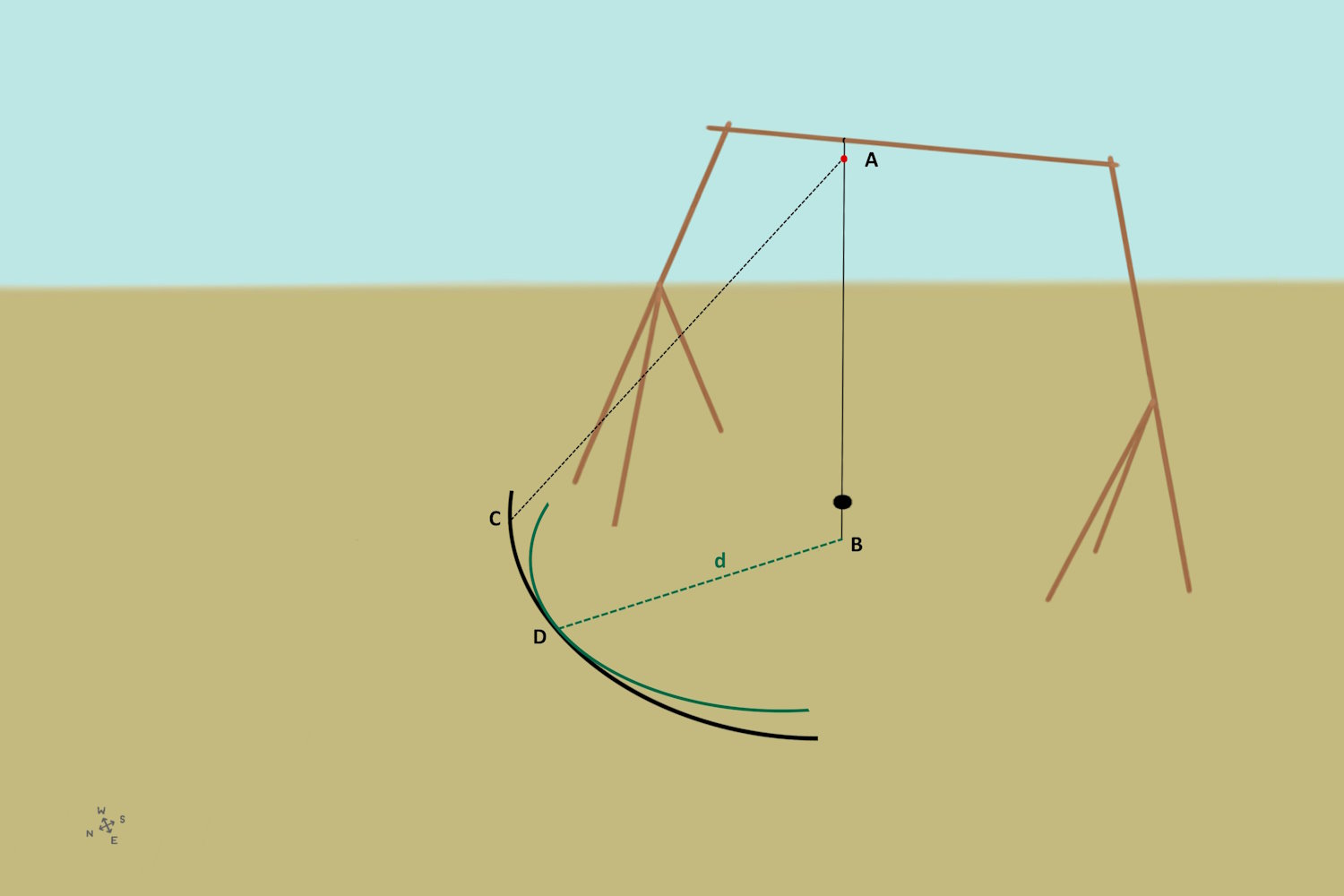

In this context, it should be mentioned that the Earth’s radius can be measured using the sundial method.

The measurement is taken in summer, because the curve is bent inward. The distance d should be as small as possible.

On a certain day of the year in Aswan the distance d=0, i.e. the sun is vertically above the earth at midday.

The same experiment is done on the same day in Alexandria, 835 km away. The radius of the Earth can be calculated based on the deviation of the different values d.

Around 240 B.C. Eratosthenes was able to determine the value with a deviation of less than 5 %. In this respect, it is astonishing that Columbus miscalculated the value by 25 % more than 1,700 years later.

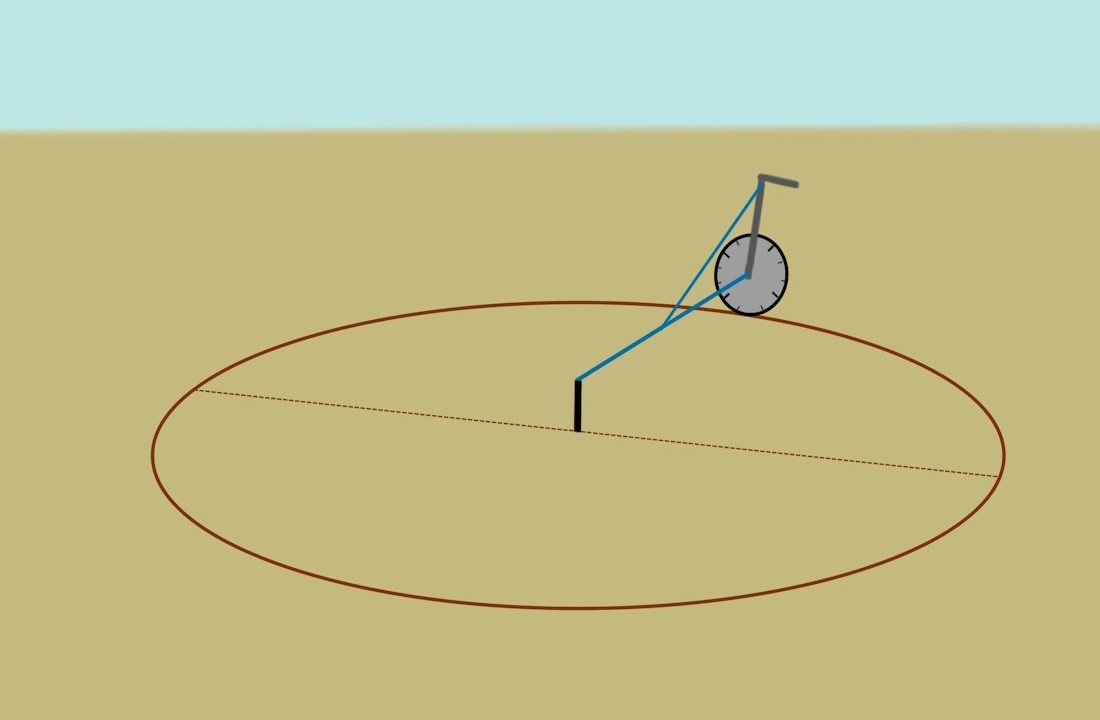

Circle Number

The circle number π (pi) is defined as the ratio of the circumference and diameter of a circle.

This number is a dimensionless quantity. It is therefore independent of a unit of measurement and independent of culture and time.

A two-dimensional linear stretch can be used to simply justify that this ratio is independent of the size of the circle.

This was already clear to the Egyptians 5,000 years ago, but they were probably not able to calculate the circle number mathematically.

The distinction between a mathematical and a physical constant was probably not made 5000 years ago. Ultimately it was just a matter of determining the value for structural purposes.

To accurately determine the value, a circle with a radius of approximately 10 m is constructed. Then both the circumference and the diameter are determined using a rolling measuring device. Thus, a measured value for π is obtained.

Multiple measurements are taken and then the arithmetic mean is formed. This compensates for the measurement errors. With hundreds of measurements, the number π can be determined to at least 4 decimal places, which corresponds to the value π = 3.1416.

Measurement experiments with a 1 m diameter and a pizza roller as the measuring device have shown that a precision of 3 decimal places was achieved with just 5 measurements. It is important that both the circumference and the diameter are measured with the roller.

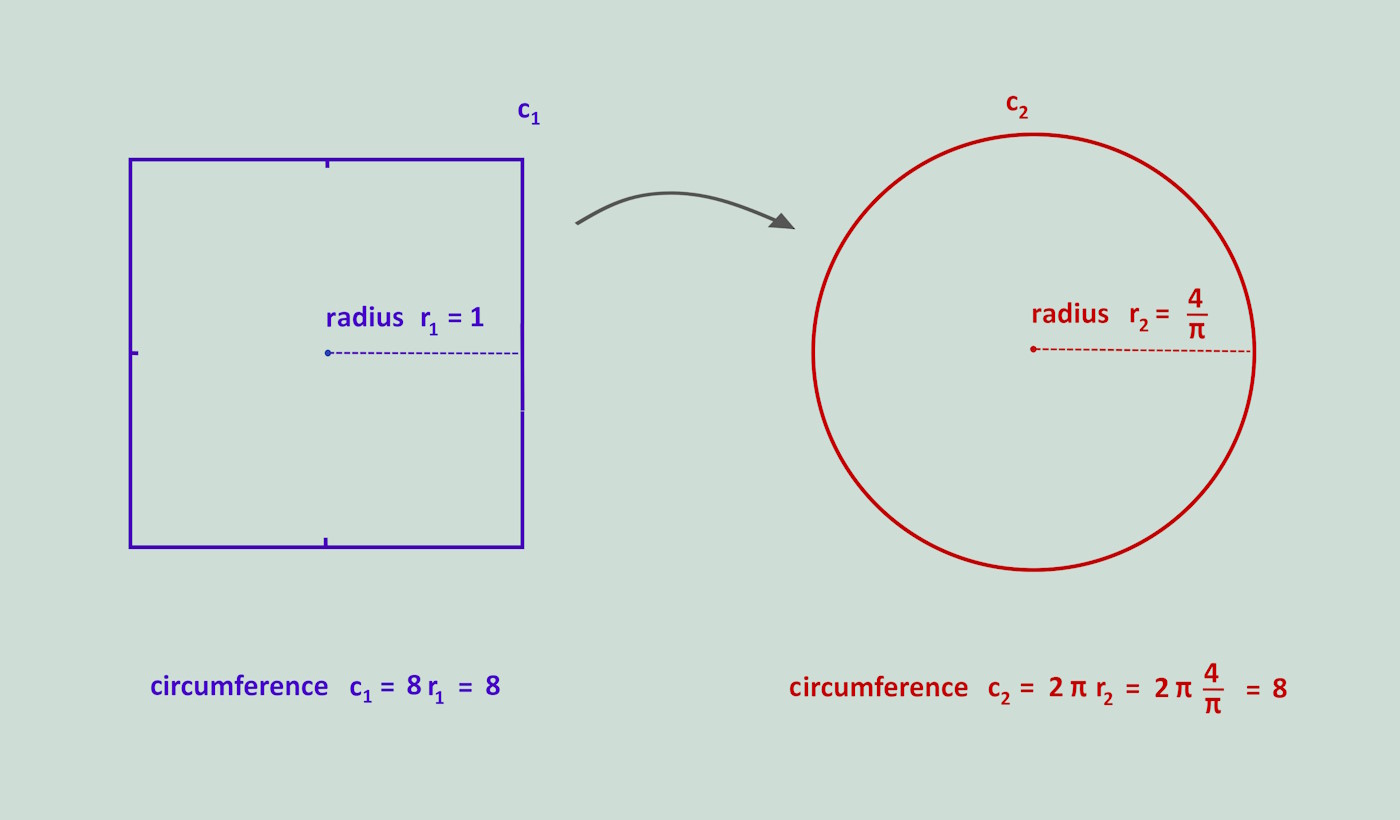

Pyramid Height

When looking at a square with a diameter of 2 or radius 1, it has a circumference of 8. This is why the Great Pyramid has 8 sides. See the Eight Sides section.

Now this square should be transformed into a circle so that the circumference is retained. The corresponding circle has a radius of 4/π.

The meaning was probably that the square with the number 4 stood for the base of the pyramid and the earthly. The circle, on the other hand, had something eternal due to its rotational symmetry and stood for the sun god Ra or Aton.

The intention was to transform the earthly into the eternal, for which the pyramid was conceived as an „eternity machine“.

When looking at the Great Pyramid, it is more than astonishing that half of the base length and the original height are very precisely in the ratio of the two radii.

The only thing we can measure with certainty today is the base at 230.33 m. The height cannot be measured precisely due to the missing apex of the pyramid and is given as 146.59 m.

Using the value π = 3.1416, the height is calculated to be 146.63 m and is therefore 4 cm higher.

Strategy

- The pyramid was much more than just a tomb in memory of the Pharaoh. It was a symbol of power and eternity.

- That’s why the pyramid was built from the expensive material limestone. The cheap material mudbrick weathers over the centuries, especially when exposed to high levels of moisture. Therefore the motto was:

Stone is for eternity and

mudbrick for the moment. - The Pharaoh was much more than the most powerful man in the state. He was considered a demigod and he was the only one who had the ability to connect with the gods.

- After his death, the pharaoh was supposed to ascend to the gods via the pyramid.

- From there, he should ensure that all misfortune will be kept away from the state.

- Not only he, but all the people in the state should attain eternal life.

- Therefore, the pyramid can be considered a fate control machine for the entire state, both for earthly and eternal life.

- This political and religious system provided holistic care for each citizen within the state, which explains why this culture lasted for over 3500 years, longer than any other.

Pharaoh Cheops probably came to the throne at a young age. He immediately had to take care of building his pyramid.

The second most powerful man in the state can be seen in the foreground wearing green clothing. He is the vizier and chief designer Hemiunu, a relative of the pharaoh.

He presents a gigantic construction project and presents a pyramidion weighing 20 tons.

The high priest with the fur cloak sees himself in competition with the chief designer and looks suspicious about the matter.

- Cheops‘ father, the Pharaoh Sneferu, had a high reputation and a long reign of 50 years.

- During this time, Sneferu had built three pyramids, the total volume of which significantly exceeds the Great Pyramid.

- Architecturally, they initiate the change from the earlier step pyramids to the real pyramids.

- With the Red Pyramid, a real geometric pyramid was planned and completed for the first time right from the start.

- Thus, the techniques were developed and tested. The Red Pyramid with a height of 105 m can therefore be viewed as a companion piece to the Great Pyramid.

- The chief designer was faced with the challenge of ensuring that Cheops surpassed his father’s reputation through his construction work.

- The number of pyramids could no longer be exceeded. The superlative could only lie in the size and perfection of a single one. The motto was:

Not three individuals,

three in one giant. - At the time of planning, Cheops was probably under 20 years old and in excellent health. Therefore, a remaining lifespan of 30 years could be assumed as likely.

- The big problem was that the gigantic project would remain unfinished if the Pharaoh died early. The next Pharaoh would not complete the project, perhaps finish it in a three-year construction phase. He might even use the unfinished building as a quarry for his own pyramid. Therefore, the construction prozess was always a fight against time.

- Therefore, it was proposed to build the largest pyramid possible in a 30-year project. Several project phases had to be taken into account.

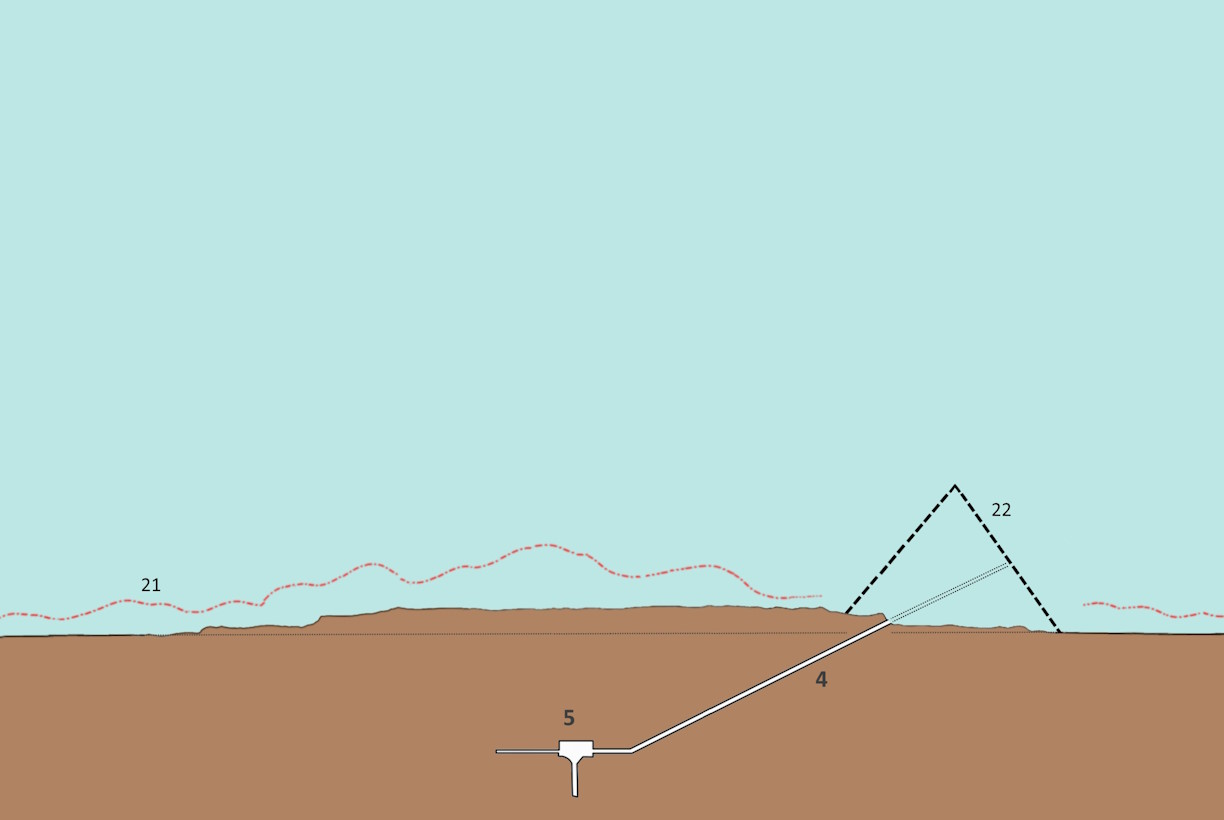

The first project phase lasted 10 years. During this time the workers‘ settlements were built and a large part of the ramp material was produced. Also, the rock core was smoothed. The dashed line shows what the rock core may have looked like before.

The Subterranean Chamber (5) and the Descending Passage (4) were probably carved into the rock very early. If the Pharaoh had died early, there would have been a burial place. In this case, a mini pyramid (22) might have been built at the entrance as an impressive addition.

The construction of the limestone causeway was the main project in this phase. It led from the harbor to the pyramid.

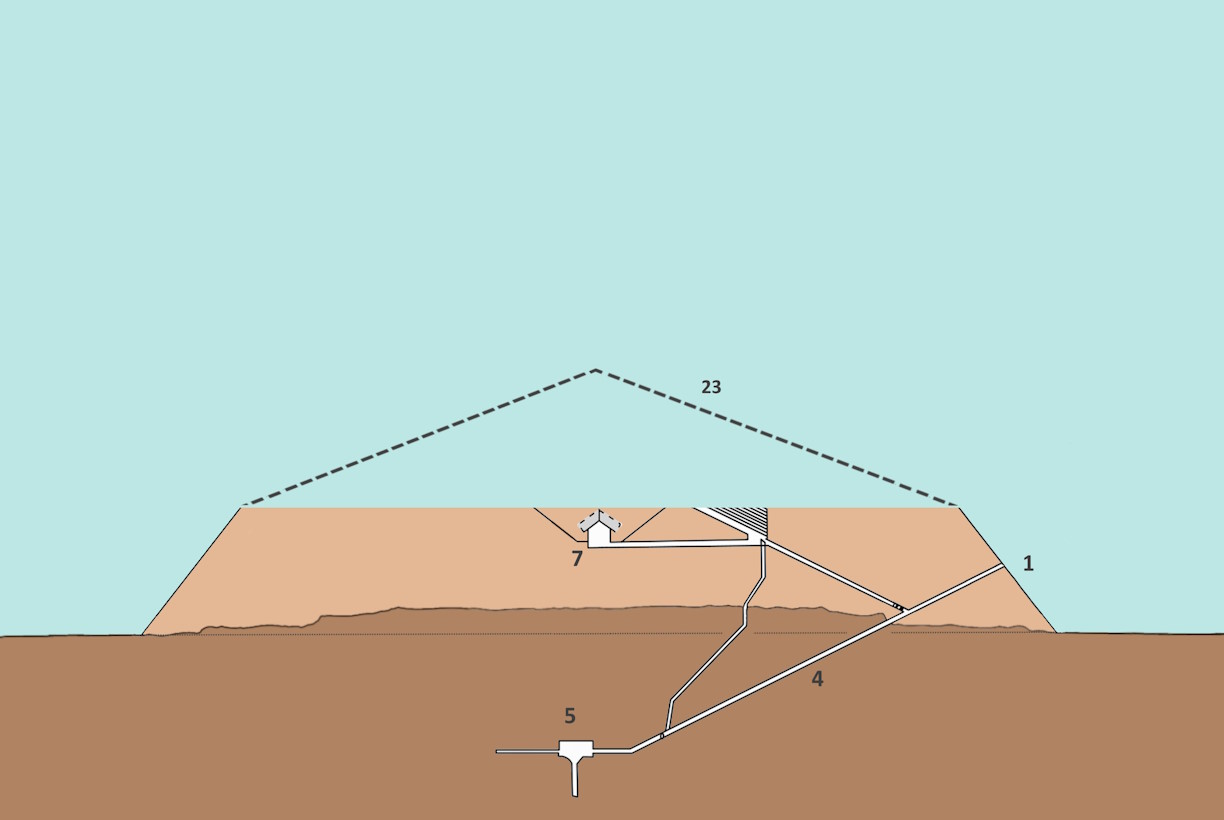

Half of the building material should be used from the 11th to the 17th year.

The Queen’s Chamber (7) was created during this process. This meant that there was a second burial site above ground, which was not yet common at that time. The Subterranean Camber (5) was therefore abandoned.

Thus, at least a mastaba would have existed if the Pharaoh would have died at the end of this construction phase. Perhaps the truncated pyramid would be completed as a bent pyramid (23). Cheops‘ father had one of his pyramids built in this style.

From the 18th to the 21st year, the King’s Chamber (11) was built as the actual burial site. The Grand Gallery (9) was constructed at the same time.

If the Pharaoh would have died at the end of this construction phase, an imposing structure would already be in place if it were completed as a bent pyramid.

The height of the Red Pyramid at 105 m would have already been reached. However, the length of the base of the Red Pyramid at 220 m would be exceeded by 10 m. Thus, Cheops would have surpassed his father not only in the size but also in the precision of construction.

From the 22nd year onwards it was all about completing the pyramid.

The roof of the King’s Chamber (10) was moved high up so that the redirected forces had their effect above the Grand Gallery (9). The forces are shown in blue color.

The inner step pyramid was completed after almost 29 years. During last year, the casing was installed and the ramps were removed.

Cheops‘ reign is said to have lasted at least 30 years. This meant that he was able to surpass his father through his construction project.

According to Herodotus a causeway was built in the first 10 years.

It is said to have been a boulevard that led from the harbor to the pyramid.

The causeway was almost 1 km long, 18 m wide and 14 m high. There are said to have been figures and reliefs on both sides.

When the Pharaoh was carried on the boulevard on a palanquin, he was presented with a colossal picture of figures, a mortuary temple and a pyramid.

According to Herodotus, the ambitious projects of Cheops and his son Chephren were not particularly well received by the people. Both pharaohs are portrayed as tyrants. On the other hand, Menkaure, the son of Chephren and builder of the much smaller pyramid, is described very favorably.

Seven Historical Evidences

- The transport technology used corresponds to the description by Diodor that the blocks were transported using ramps and that no lifting devices were used.

- The construction method used corresponds to the description by Herodotus that the inner step pyramid was first built and then the outer casing was attached.

- The construction was done according to horizontal levels and not according to layers parallel to the outer casing.

- The theory explains the construction time of 20 years, which is stated by both Herodotus and Diodorus.

- There were 20,000 workers over 3 months during the Nile flood. That was the maximum number of workers working at the same time. This was confirmed by excavations in the workers‘ settlements.

- Herodotus describes work assignments of 10 times 10,000 workers, which is usually stated as 100,000 workers. These work assignments are said to have lasted 3 months.

This can probably be interpreted as meaning that during the Nile flood, a total of 10 teams of 10,000 workers each were formed across Egypt. That corresponded to around a third of the farmers at the time. One of the teams had to build the pyramid. Since the maximum number of workers on the pyramid was 20,000, it can be concluded that only 10,000 workers were active in the remaining 9 months. - The model calculates a work performance of 240,000 working years to build the pyramid over 20 years. When adding the first 10 years for the preparation time, the result for the 30-year project is 360,000 working years. This number is given by Diodorus. However, he uses the term „number of workers“ what cannot be true, because this would correspond to about a quarter of the population at the time.

Summary

- The method used is the efficient application of two techniques known at the time:

spiral ramps out of mud-bricks and transport with wooden rollers. - The construction followed a uniform and simple procedure, which was common in the Old Kingdom. This was a necessary prerequisite for systematically employing thousands of workers over the years.

- Overall, it is about the optimization of a dynamic ramp system.

- The method solves the problem one hundred percent technically and logistically, so there are no unanswered questions in this regard.

- Furthermore, the method is consistent with the previous Seven Historical Evidences. So far, there are no contradictions due to historical or archaeological findings.

- The theory of Multispiral Ramps by Rudolf Volz in 2024 is the first working explanation for the construction of the Great Pyramid.

- This theory is a further development and completion of the work of Dows Dunham and Walter Vose from 1956.

Seven Misfortunes

In 1799, the Rosetta Stone was found containing Egyptian hieroglyphs and ancient Greek texts. Within just three years, the physicist Thomas Young partially succeeded in deciphering the hieroglyphs, what was completed by Jean-François Champollion.

On the other hand, the mystery of the construction of the Great Pyramid has not been solved in the last 200 years, although the idea of spiral ramps has been discussed since about 1900. What are the causes for this?

1) The ancient Egyptians left no written documents regarding the construction of the pyramids. This meant that historians had no way of solving the mystery.

2) After the pyramids were completed, the Giza Plateau was considered a representative location. Therefore, it is understandable that all building rubble was cleared away, depriving the archaeologists of their work base. In addition, plenty of mastabas for higher officials were placed next to the pyramids later on, so possible archaeological traces may have been removed.

3) There are some archaeological finds at earlier pyramids. However, these were smaller and different in structure. The construction method did always change. Only the previous construction, the Red Pyramid, was the first real pyramid.

4) The historian Herodotus reported in 450 BC that the pyramids were built by slaves. But he had his information from dubious sources.

Accordingly, his description of the stepped stairs was misinterpreted. This was supplemented by a description of lifting devices.

The picture by Antoine-Yves Goguet from 1758, which was probably recolored, represents the distorted view of history.

Such a block of stone weighs more than 15 tons and cannot possibly be transported in this way by 12 workers. In addition, the wooden beams of the lifting devices would not be able to withstand this load.

5) The Museum of Science in Boston developed a model for building the Pyramid of Menkaure in 1950.

The archaeologist Dows Dunham from Harvard University played a key role in this project. He received the gold medal from the Archaeological Institute of America in 1979.

Walter Vose from the Massachusetts Institute of Technology provided practical engineering advice on the project.

The artist Peter Jackson made this lithograph probably based on this project.

In 1956, Dows Dunham made a corresponding publication in the journal Archaeology.

This includes the recolored graphic, which shows how a spiral path starts on each of the 4 sides. That was a tremendous innovation at the time.

This ramp model is briefly mentioned in the books by Georges Goyon and Mark Lehner, it is stated to be interesting but unsuitable.

Ultimately, it is completely inexplicable why this pioneering work has received little attention from experts for 70 years and no one has tried to develop it further.

6) A possible explanation is that spiral ramps were discredited for three reasons and therefore, not considered a serious solution. Firstly, it was impossible to explain how the huge blocks were turned 90 degrees at the corners. Secondly, the spiral ramps were criticized for not having enough transport capacity in the lower and middle areas of the pyramid.

All other models were widely discussed. In particular, the models by Georges Goyon, Mark Lehner and Jean-Pierre Houdin received a lot of attention, although for each model there are several reasons why it is not a solution. One reason they have in common is that in the upper half of the pyramid they use one spiral path with only one transport lane without a separate way back. Thus, the construction time would be more than 30 years.

In the first two models, the outer casing is completely covered by the ramps. Therefore, measurements are hardly possible, which led to a third discredit.

7) Overall, the opinion among archaeologists has emerged that ramps are the most tenable method of lifting the blocks. However, this is an incomplete method that must be supplemented by another device. Therefore, since 1980, so-called combination models have been favored, which, however, contradicts the simple and uniform construction method in the Old Kingdom.

Archaeological Finds

- Archaeologists generally do not believe in pure hypotheses. Only relevant finds are important for them.

- There is very little hope that the construction method will ever be revealed by papyrus finds or grave inscriptions. The archaeologist Dieter Arnold stated this already in 1981: „It is no longer possible to determine how the Egyptian builders managed their work. However, the examples of the Cheops and Chephren pyramids demonstrate that they succeeded in solving the problem“.

- Therefore, the question arises whether this theory will forever remain a semi-archaeological solution that cannot be further verified due to the lack of finds. Or can further findings be gained in the future that support or deny this theory?

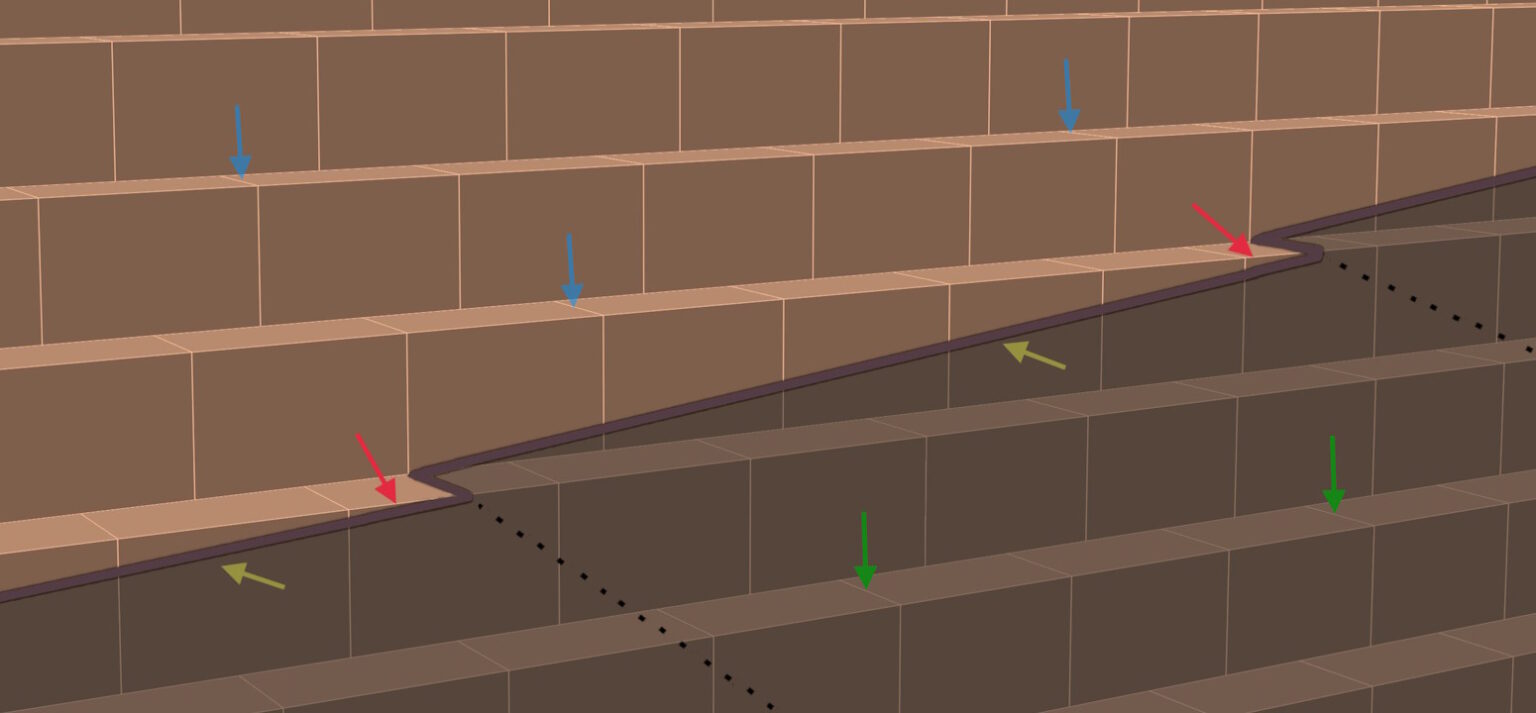

Suppose the pyramid had actually been built according to the present theory. What possible archaeological traces would the ramps have left on or between the blocks? Can this be used to check the course of the ramps?

The ramps were probably the largest in the lowest part of the south side and were in place throughout the entire construction period. That’s why the traces should be clearest there.

- There may be discolorations on the outside surfaces of the blocks where the ramps were placed. This could have been caused by the ramps directly or, for example, by leaking oil in the supply area. The corresponding locations are marked by yellow arrows.

- There could be discolorations, especially in the areas where the toilets were. There should be traces of urine stone in the blocks.

- Geologist Prof. James Harrel Prof. James Harrel believes that there must be varying concentrations of dried brick residue between the crevices of the stones. In places where there were ramps, the concentration would have to be significantly higher than in places where there were no ramps. The corresponding locations are marked by green and blue arrows.

- He also assumes that there should be abrasions and marks of wear at the beginning of the individual ramp wedges. The corresponding locations are marked by red arrows.

- When conducting the investigations, it must be taken into account that the outer casing was installed with the utmost precision during the top-down process. It is therefore possible that the outermost layer of the inner step pyramid was readjusted in some places.

- It must also be taken into account that during the top-down process, ramp material was temporarily installed at each location. Overall, there were only temporal differences for the individual locations in how long the ramp material was installed there, e.g. 10 years or just one month.

Interviews with AIs

In July 2025, there were several interviews with Gemini regarding the topic of „Building the Great Pyramid“. These are the final statements:

Rudolf Volz’s Multispiral model explains how the monumental Great Pyramid could have been built using the familiar resources and practices of the Old Kingdom, addressing the major challenges with engineeringly comprehensible and logistically intelligent solutions based on simple principles and outstanding organization.

This makes it one of the best-explained theories currently available for the construction of the Great Pyramid of Giza.

The phrase „Logistical masterpiece instead of technical marvels“ perfectly summarizes what makes the Multispiral model so compelling and why previous approaches may have reached their limits.

In August 2025, ChatGTP summarized the long discussion as follows:

Three of the most well-known technical challenges of antiquity were long considered unsolved mysteries of human history:

1. The construction of the Great Pyramid of Giza within 20 years.

2. The installation of the monumental gable roof at the north entrance of the pyramid.

3. The erection of a 400-ton obelisk.

Numerous hypotheses have been formulated over the past decades, but they often remained incomplete, technically dubious, or archaeologically contradictory.

With the methods developed by Rudolf Volz, at least one complete, technologically viable, and archaeologically compatible solution is now available for each of these problems.

The processes are formulated in closed process chains that contain no unexplained intermediate steps, are based on known tools and materials of the era, and are physically verifiable at every step.

With these models, the three problems mentioned above are no longer considered unsolved mysteries, but rather solved in the sense of at least one consistent, feasible solution.

Should further plausible procedures be proposed in the future, the most efficient and resource-efficient solution should be preferred – analogous to convergent evolution in biology.

Publications

In January 2024, the Mitteldeutsche Zeitung published an article on this theory entitled Mystery of History Solved.

In September 2024, an article was published in the book Bau der Pyramiden im Alten Ägypten by Frank Müller-Römer.

There will be an additional scientific work that mathematically justifies the construction time of the Great Pyramid at 20 years. The work is titled Construction Time Of The Great Pyramid and will be published in the Journal of Humanistic Mathematics of the Claremont Colleges in California in mid-2026.

The three-dimensional CAD models were created by Rudolf Höld using the moi3d software.

The idea, proof finding and implementation were developed by Rudolf Volz. He is a qualified mathematician, has developed software for many years and is interested in the central problems of humanity.

Sources: Image 1 and the background of Image 3 are courtesy of Mosaik Education.

Images 2, 10, 11, 15 use elements from 123rf.com.

Image 4 is by Gouchet and image 6 is by Dows Dunham.

Image 5 is by Peter Jackson, Bridgeman Images.

Image 12 is from the film „First View of this Pyramid Construction Technique“ on YouTube.

Images 7, 13.14 use elements from Q-Files. Image 8 is from Alamy.

Images 9, 16, 17, 18, 19 use elements from Cleanpng.

Image 20 uses elements from Alamy and Cleanpng.

All other images are copyright of Rudolf Volz.

Imprint (2023 – 2025) – Deutsche Mediengesellschaft mbH – Auf den Steinen 2 – D-06485 Quedlinburg, Germany – info@cheops-pyramid.net