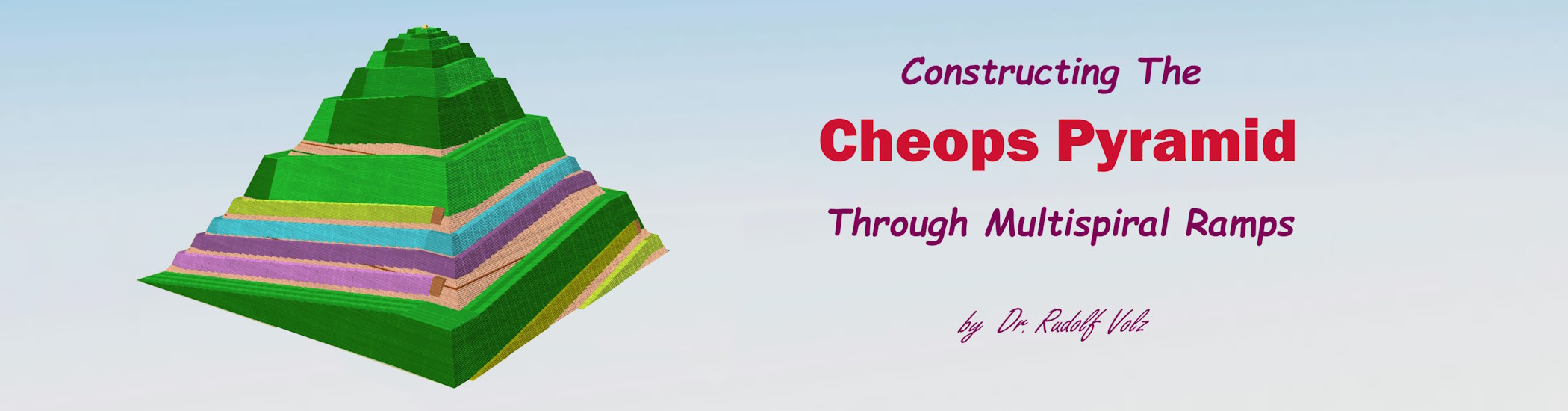

Constructing the Cheops Pyramid Through Multispiral Ramps

The Cheops Pyramid is the largest Egyptian pyramid and is therefore also known as the Great Pyramid.

The following explanatory model aims to fully and consistently reconstruct the construction process of the Great Pyramid. Its central task is the continuous mass transport of 3 million standard blocks, each weighing 2.3 tons, which constitutes 99 % of the building material. The construction of the pyramid is therefore understood as a massive logistical project.

Archaeological finds do not serve as direct proof of the construction method, but solely for consistency checks. The model provides criteria for potential falsification.

If several technical solutions exist for a given location, the one with the highest efficiency is chosen. This was the only way to construct the monument within 20 years under humane working conditions. Therefore, efficiency becomes the second source of information.

The document FAQ answers the frequently asked questions, and the document Deductive Model contains all essential information in bullet points.

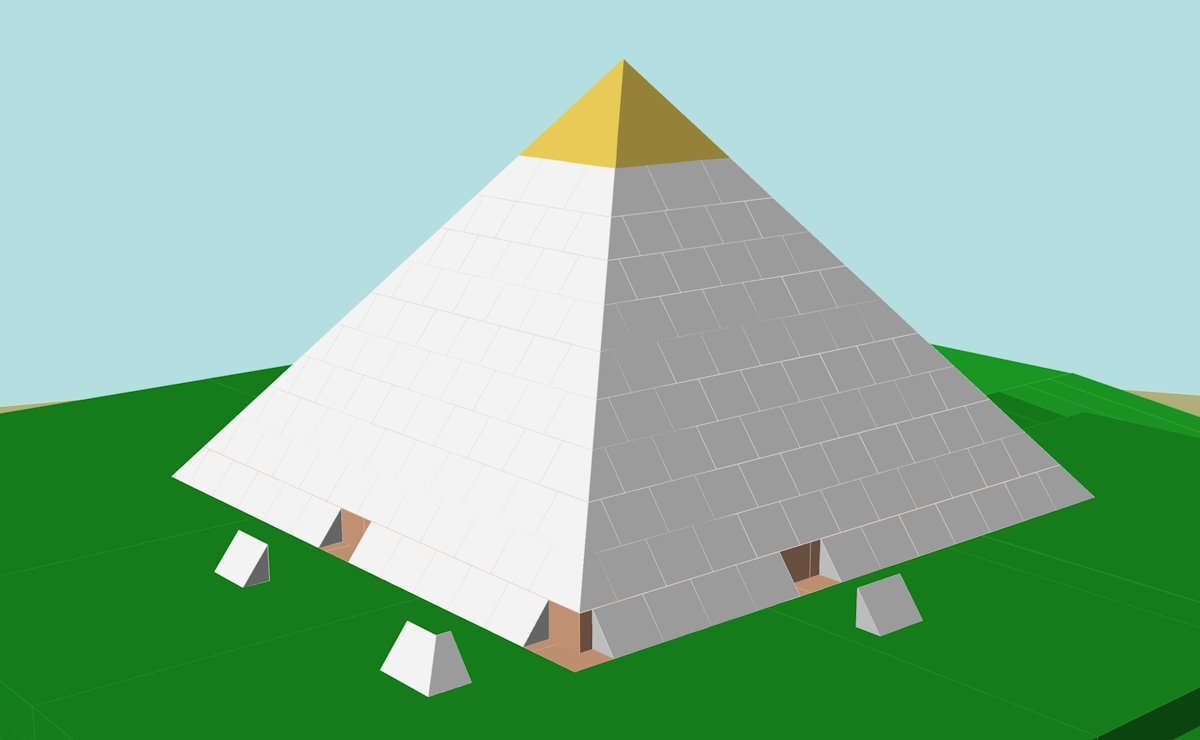

The image shows the Pyramids of Giza from 4500 years ago. There is also a 3D representation of this.

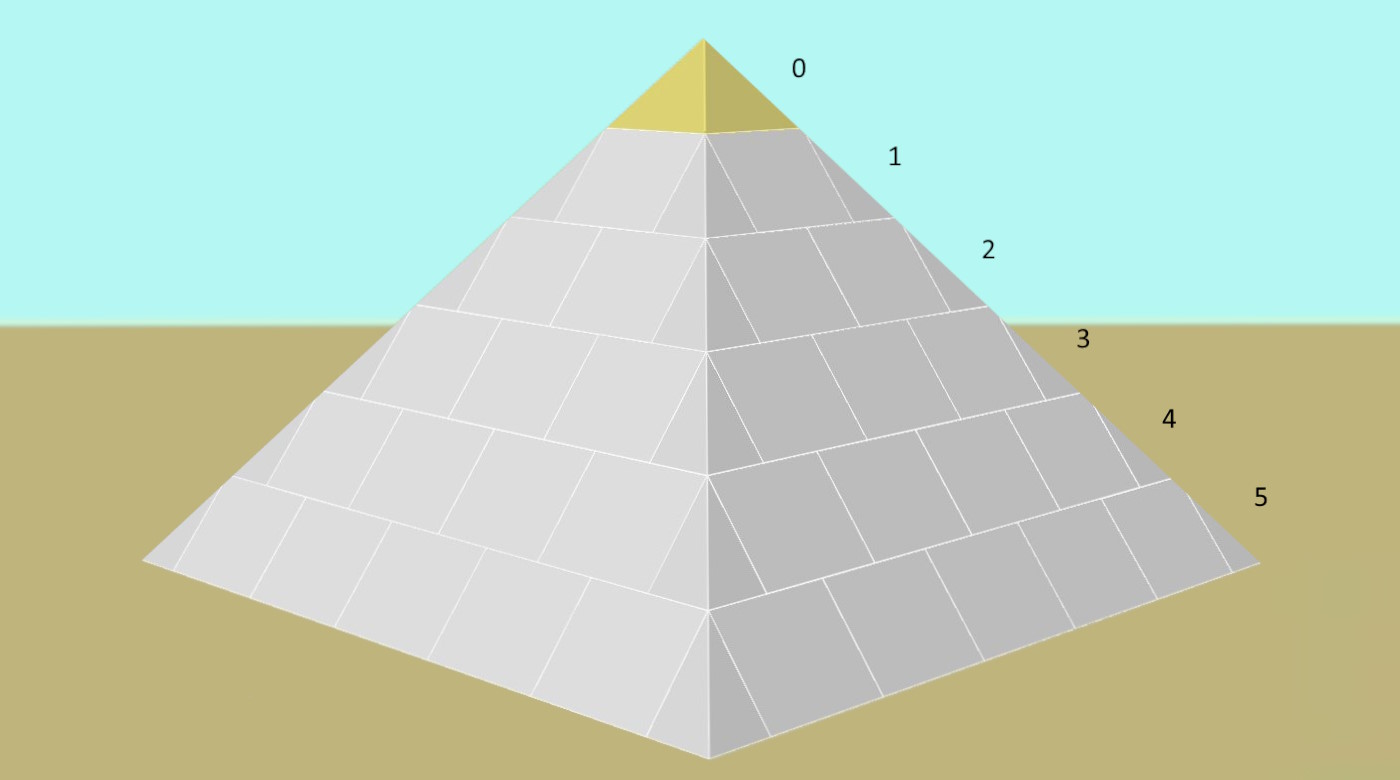

The casing out of white limestone made the pyramids appear like diamonds in the sunlight.

Overview

External Ramp

Internal Ramp

Theory of Multispiral Ramps

Uniform Pyramid

Ramp Construction

Multispiral Model

Towing Team

Construction Time

Workforce

Turning At Corners

North Entrance

Huge Blocks

Zigzag Lifting

Pyramidion

Outer Casing

Eight Sides

Magnitude

Real Pyramid

Stability

Measurements And Precision

North-South Direction

Circle Number

Pyramid Height

Strategy

Seven Historical Evidences

Summary

Seven Misfortunes

Archaeological Finds

Interviews with AIs

Award

Publications

- Although the Great Pyramid is one of the most impressive structures of mankind, there are almost no documents or archaeological finds that indicate its construction technique.

- The pyramid builders belonged to a high guild, which probably kept their knowledge extremely to themselves. Therefore, they ensured that no permanent documents or traces remained.

- According to the two historians Herodotus and Diodorus, the construction time was only 20 years.

- How could the Egyptians in the Old Kingdom build this pyramid?

There are many theories about this, but none can satisfactorily explain the construction method.

Therefore, this problem is considered as a mystery of mankind.

External Ramp

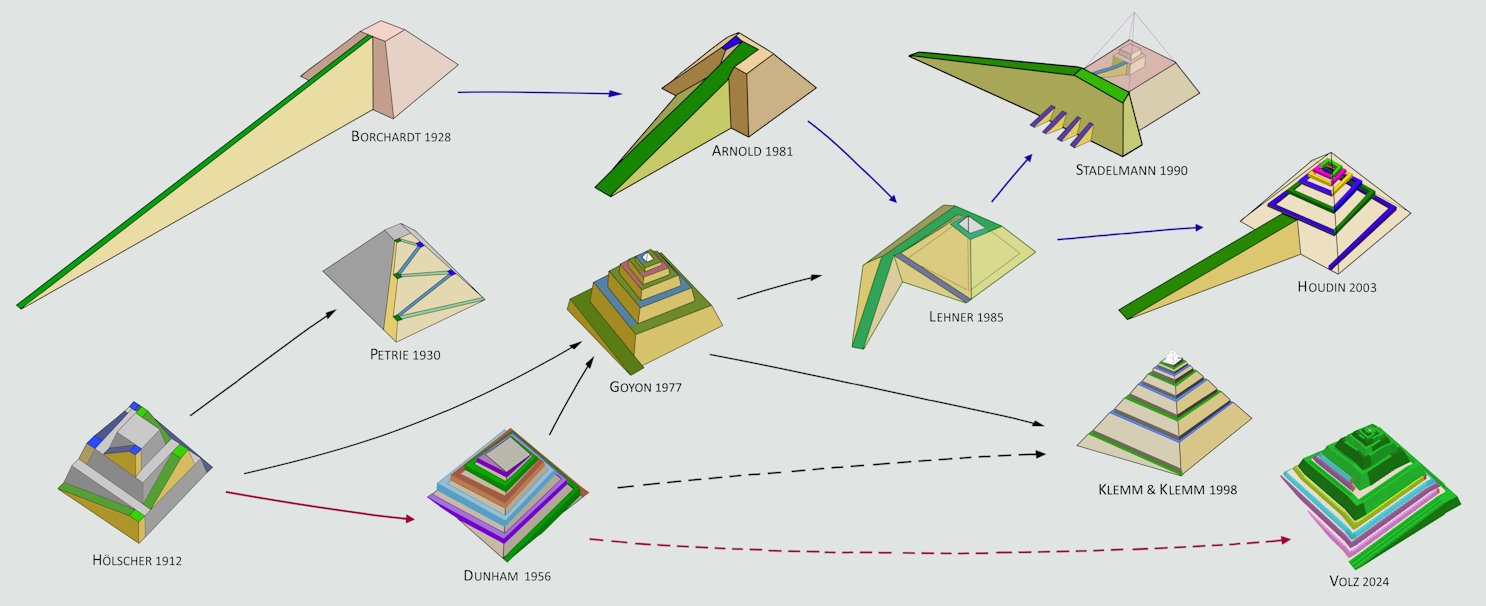

Using an external ramp seems to be the most immediate method. This ramp model was proposed by Ludwig Borchardt in 1928.

With an inclination angle of 6.6 degrees or 11.6 %, the ramp would have a length of 1.3 km and a volume of 160 % relative to the pyramid.

Since the two neighboring pyramids did not exist at that time, the ramp could have looked like demonstarted in the image. This is probably the only way to place an external ramp in this landscape.

- It would take more than 10 years to remove this ramp. Therefore, it is impossible to complete this monument within 20 years

- If this critical time limit would not exist, then the external ramp would have been considered as a possible solution to the problem for long.

Internal Ramp

In 2003, Jean-Pierre Houdin introduced his theory of the internal ramp, which uses two separate ramp systems.

This theory has generated great fascination worldwide through computer simulations. However, the crucial aspect, namely functionality, is never questioned.

1) A straight external ramp leads to 30 % of the height, what allows to install 65 % of the material.

2) The remaining material is installed using an internal ramp, which requires a second technique.

The internal ramp, which is 2.6 m wide, has only a single transport lane. Therefore, the construction of 35 % of the material would take at least 20 years. Thus, the total construction time of the pyramid would be at least 30 years. To achieve the unavoidable construction time of 20 years, there would have to be an average of more than 2.5 transportation lanes in the upper 70 % of the pyramid. See the Construction Time section.

3) In the upper 15 % of the pyramid, the inner ramp technique leads to a dead end (light green). Space within the pyramid becomes increasingly limited, and the tunnel project cannot continue. Therefore, the construction of the uppermost part of the pyramid and the setting up of the pyramidion must be accomplished using a third technique.

4) For the way back, a wooden frame (dark green) is installed, which represents a fourth technique. The wooden frame rests on the stones of the outer casing and is only supported by the bosses of these stones, what is a high risk of accidents.

5) For the smoothing process of the outer layer, an additional wooden frame must be attached around the pyramid, which must be moved from top to bottom according to the smoothing process.

A construction method using at least five different techniques contradicts completely the customs of the Old Kingdom, according to which the construction method was simple and uniform. Only in this way could thousands of workers be organized.

A large-scale project with an absolute goal of completion would not have been viable under these circumstances.

Therefore, other solutions must be found.

Theory of Multispiral Ramps

This section contains the essential informations on the Theory of Multispiral Ramps. Detailed information, including calculation tables, is provided below.

- The construction of the pyramid was the largest and most important project in the state.

- This required a clear and controllable technology, otherwise the project would never have been started.

- The pharaoh had to be alive when the pyramid was completed.

Therefore, the construction period was set at 20 years. - The slope of the pyramid was determined for symbolic or political-religious reasons:

Slope = 4/π - Then the task was to build the largest possible pyramid in this format.

There were two limitations:

– Construction time of 20 years,

– Average number of workers of 12,000 under normal working conditions. - This determined the height of the pyramid to be 146.59 m.

- Overall, this is an early optimization problem:

To create the largest possible pyramid under certain constraints.

This task could only be solved by the earliest mathematicians. - A precise construction plan and schedule had to be submitted, specifying which height would be reached at what time.

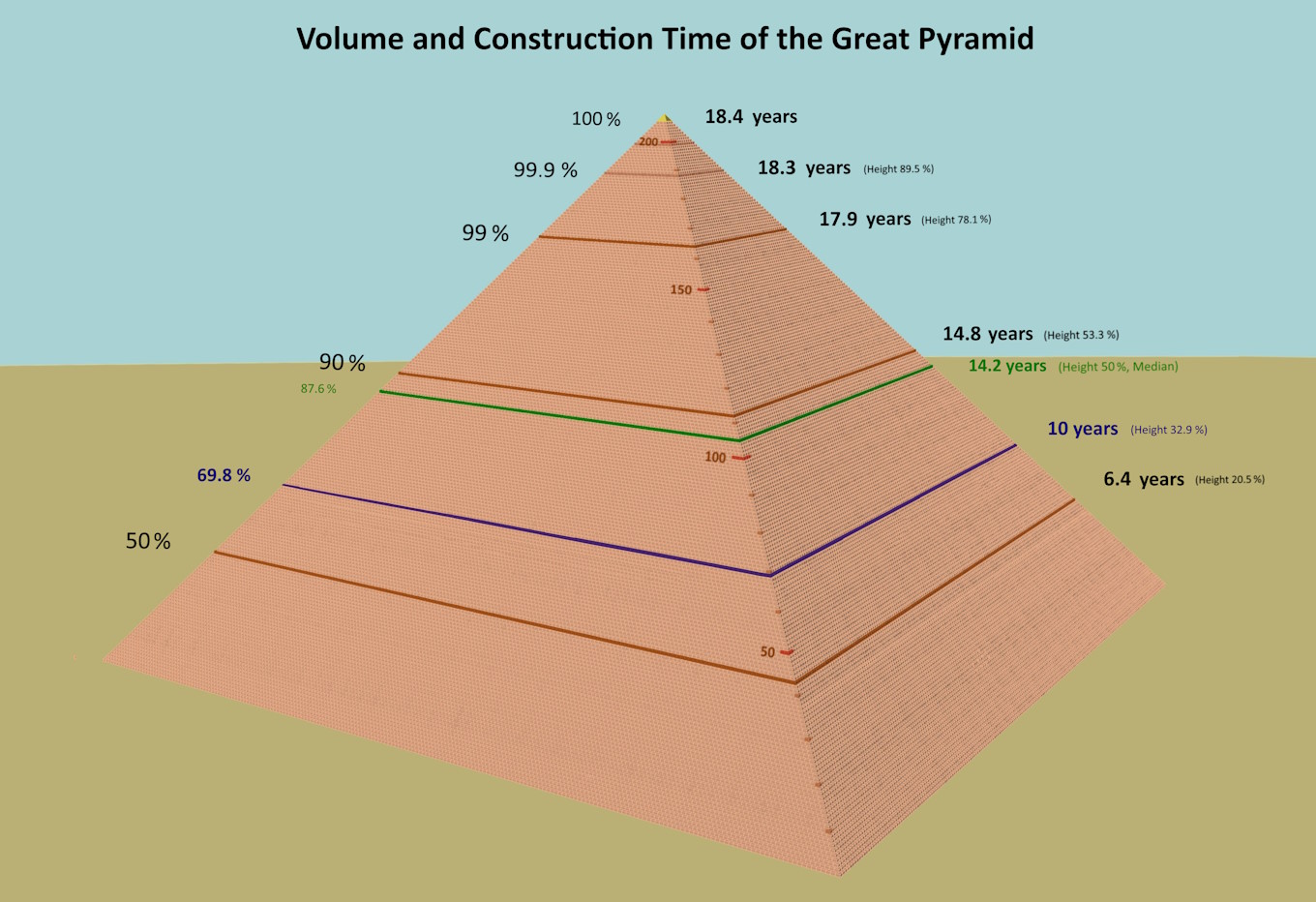

For example, „After 10 years, one third of the height will be reached and 70 % of the material will have been used.“

See the Overview Image. - Therefore, the most efficient method had to be applied at every stage of the construction process.

Deciphering the construction process is therefore quite analogous to convergent evolution in biology. - Using several spiral ramps is the most efficient construction method:

– The system has sufficient delivery lanes,

– There is a separate return path to avoid collisions,

– The delivery of stone blocks and the construction of the ramps can be carried out independently of each other,

– The ramp material accounts for only 6 % in comparision to the pyramid’s volume.

See the Multispiral Model section. - The transport method using wooden rollers is the most efficient.

The method using sliding sleds on wooden beams also requires numerous water carriers and wider ramps.

See the Towing Team section. - The construction method follows a simple and uniform line, as was common in the Old Kingdom.

- The construction method is consistent with the few archaeological finds and historical evidences.

- The task of future archaeologists will be to examine the outermost layer of the pyramid for ramp traces.

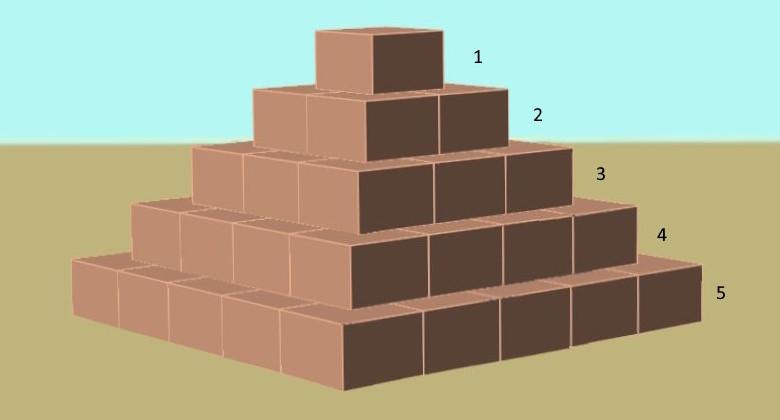

Uniform Pyramid

Then the inner step pyramid is decorated with an outer casing. The corner and deco stones of the casing are placed on the steps of the inner pyramid.

There is an additional level with a gold-plated keystone at the very top. This stone is a mini pyramid and is called pyramidion.

The Great Pyramid consists of 210 levels including the Pyramidion. As a uniform pyramid, the Great Pyramid would have 3 million blocks.

The lowest red line indicates the height at which half or 50 % of the material was installed. This process took 6,4 years and only a height of 20.5 % was reached at that point.

The blue line shows the height after half of the construction period or after 10 years, where one third of the height has been reached and 70 % of the material has been used.

The green line stands for half of the height or the median. This construction phase was reached after 14.2 years.

Thus, for many years the Pharaoh saw only a truncated pyramid which did slowly grow.

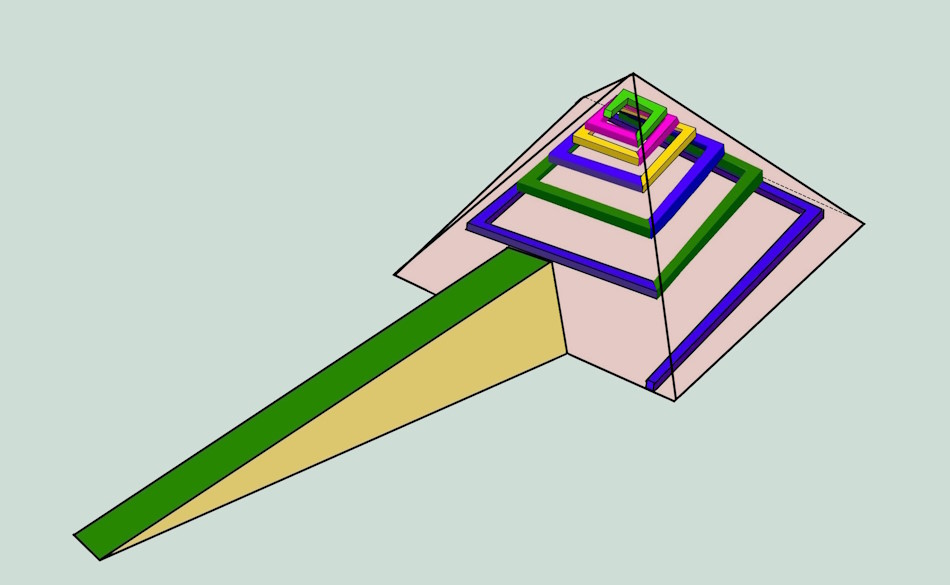

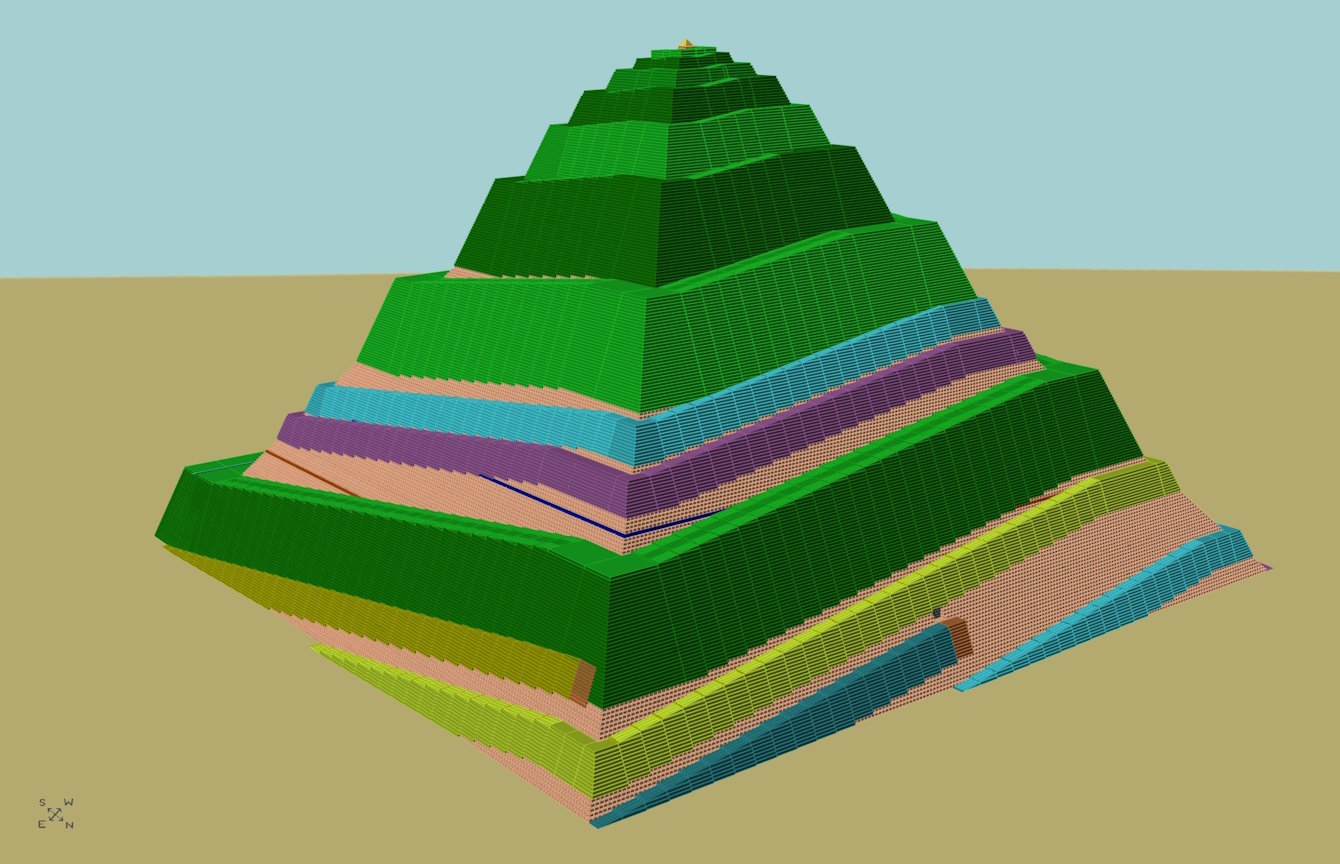

Multispiral Model

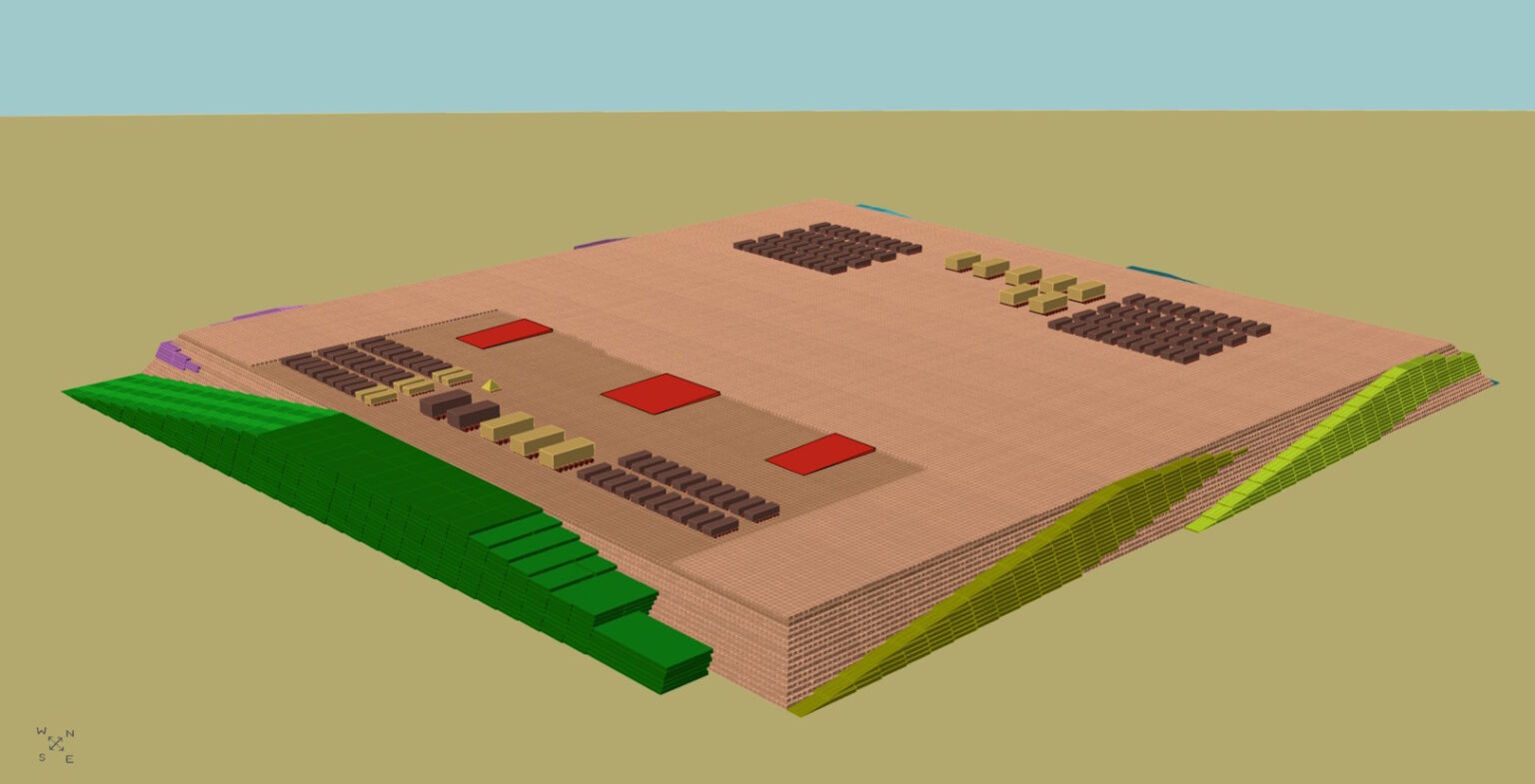

The main green path begins on the south side, about 400 m from the quarries, from where 99 % of the material is delivered. See the image of the Giza Plateau.

The main ramp leads to the top of the pyramid. In the upper third of the pyramid, the ramp paths partially rest on the path below. This creates a working platform at the top of the pyramid, allowing the pyramidion to be placed on top.

When transporting a block from the bottom to the top, a distance of 1.8 km is covered and 7.5 circuits are made. The transport takes 8.8 hours. The values are given in detail per level in Table 6.

On the other 3 sides there start 2 ramps with only one transport lane.

These 6 single paths end at different heights. The ends are marked in red.

The entire model consists of 7 spiral paths.

The dark blue ramp ends at the north entrance which is marked in black. This was a restricted access area.

- The green main ramp has 6 lanes in the initial phase. The outer 3 lanes are marked by orange lines. After the first turn of the ramp after 5 years, the outer 3 lanes can be dismantled and the ramp material can be reused further up. Compare the images Construction Time and Huge Blocks.

- The dynamic ramp construction is carried out in 3 steps, whereby 40 % of the ramp material is recycled or saved.

- The total ramp material has a volume of only 6 % of the volume of the pyramid. This is a huge advantage over the external ramp, which has a volume of 160 %. The values are given in detail per level in Table 7.

- The many ramp paths make it possible to create a working platform at any location for the later application of the outer casing.

Towing Team

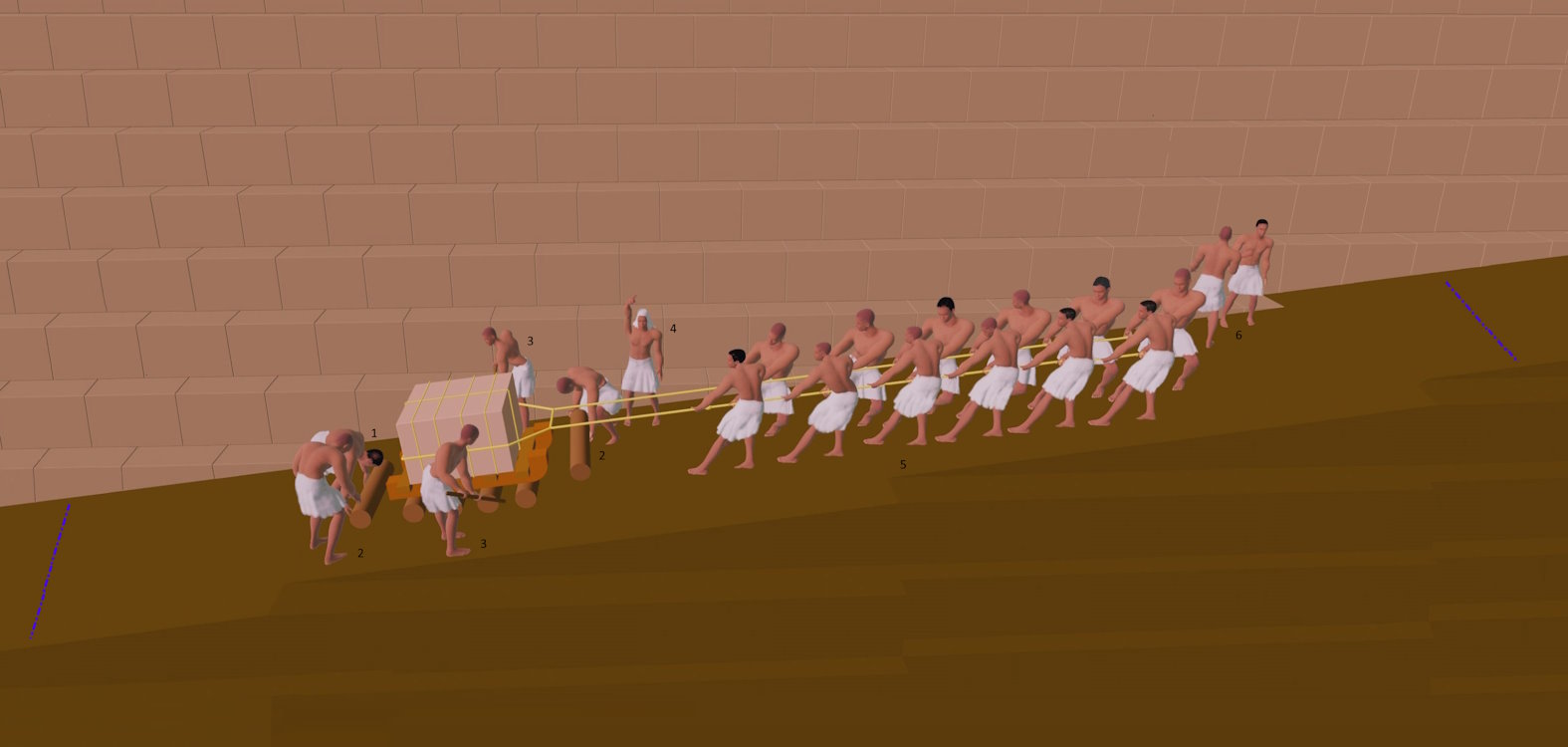

A towing team of 20 workers is required to transport a 2.3 ton block.

At the command of the commander (4), 12 workers (5) pull simultaneously for 1.3 seconds with a force of 23 kp. This moves the sledge with the block by 25 cm. During the pulling movement, the workers make the same sound.

The two workers (6) on the right are enjoying the break.

The two workers (3) with the wooden bares ensure that the rollers remain parallel and do not jam.

After the pulling movement, the sledge stands for 2.7 seconds while the towing workers (5) reposition themselves.

The two workers (3) clamp the wooden bars between the rollers, what prevents the sledge from rolling back.

The worker (1) on the far left must always stand behind the sledge and catch the rollers. This prevents the rolls from falling off the pyramid, which is a massive risk of accidents.

The two workers (2) transport the rollers from back to front and reposition them.

- Each transport lane has a width of 3 block lengths or 3.3 m.

- After a ramp length of 5.5 block lengths or 6 m, the height of one level or 0.7 m is reached.

- Within 4 seconds the team moves 25 cm, which corresponds to a speed of 3.75 m/min.

- The teams have a freedom of movement of 18.75 m. This is marked with the blue lines.

- One block can be delivered per lane every 5 minutes.

- Thus, 0.2 blocks are delivered per minute.

- This corresponds to 12 blocks per hour.

- For a working day of 12 hours per day in two shifts, this corresponds to 144 blocks per day and per lane.

- All teams must move at the same speed to avoid jams.

- The workload of the workers over 6 hours with rotating breaks and relaxation on the way back can be compared to today’s working conditions and in no way corresponds to slave conditions.

- To ensure smooth transport with rollers, the surface of the ramps should be kept flat and stable.

In the literature, there are almost exclusively presented a transport method in which sledges were pulled over wooden beams. The beams were constantly lubricated with Nile mud to reduce friction.

A towing team would consist of 25 workers and would be 5 workers larger than when transporting with wooden rollers due to the higher friction.

However, water carriers were required in addition when using Nile mud.

- The water carriers would have to deliver the Nile mud not only at the end of the delivery lane, but for all towing teams along the entire transport lane.

- When building the upper half of the pyramid, the routes are longer than 1 km and up to 80 teams would be on one transport lane. Therefore, the number of water carriers would increase considerably.

- The water carriers would require a separate walkway as they are large in number and would move at 4 times the speed of the towing teams. This way is marked by the two blue lines. Therefore, the ramps would need to be 20 % wider. This would increase the ramp volume by 44 %. The same applies to the number of workers for ramp construction.

- For example, let’s look at level 112, where 90 % of the volume was built up. At this point, an additional 1,747 water carriers would be required, which are missing for other tasks, as shown in Table 8. In this case, the number of blocks installed per day would be 279, whereas the corresponding number for the transport method using wooden rollers is 380.

- In addition, the workers would have difficulty moving on the slippery transport paths.

- Under the same working conditions, it can be said that with this transport technique, the construction time would increase by 6 years and the total work by 33 %. The detailed values and comparison are shown in the appendix of Table 8.

- The greatest possible efficiency was required at every stage of the process, because the project was a fight against time.

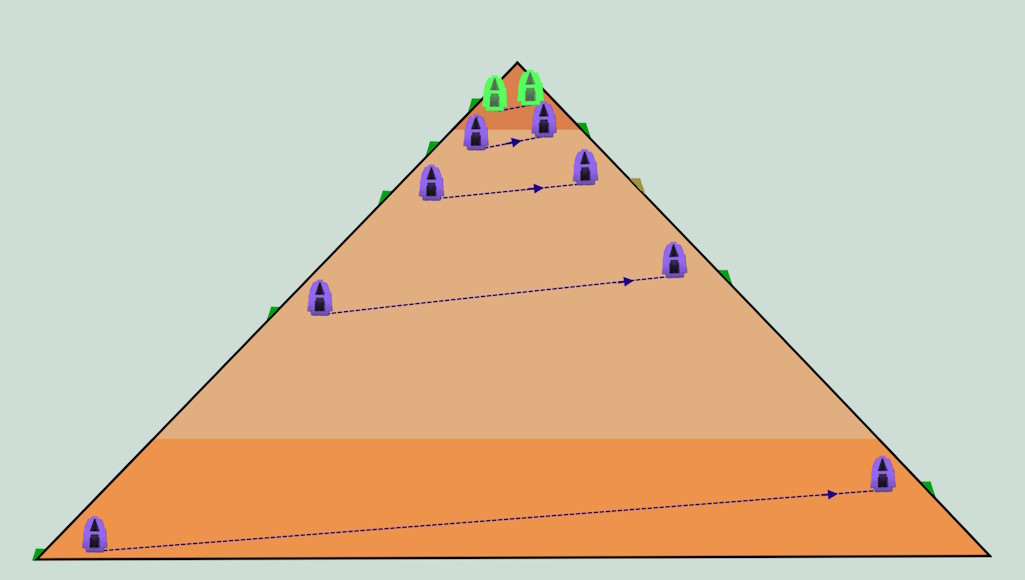

Construction Time

The image shows level 112, where 90 % of the material has been installed.

At this stage, the main green path has only 3 lanes in the lower section. The ramp material from the remaining lanes has been transported upwards for dynamic reuse.

There are also the light blue and dark purple paths, each with one lane. In total, there are 5 lanes leading to level 112.

One of the 5 transport lanes was used exclusively for the way back. This enabled a circular movement without collisions.

This leaves 4 lanes for the delivery of the blocks.

- Level 112 has a width of 210 – 112 = 98 block widths.

- Therefore, this level consists of 98 ⋅ 98 = 9,604 blocks.

- There can be 144 blocks delivered per day and per transport lane.

This requires 6 ⋅ 144 = 864 workers in the quarries. - At full capacity, there are 54 towing teams on one lane.

This requires 2 ⋅ 20 ⋅ 54 = 2,160 workers per day over 2 shifts.

The exact method of calculating the number of workers is shown in Table 2. - The productive workforce is calculated as 864 + 2,160 = 3,024 workers.

This represents 66 % of the workforce. - A total of 3,024 ⋅ 100 / 66 = 4,582 workers were needed to operate one delivery lane.

- During the three-month Nile flood, the maximum number of 20,000 workers was available.

Therefore, 20,000 / 4,582 = 4.36 lanes could have been operated. - In the upper half of the pyramid, the maximum number of workers could no longer be utilized because space became increasingly limited as one ascended. Physically, only 4 delivery lanes were available. For details, see Table 1.

This allowed for the delivery of 4 ⋅ 144 = 576 blocks per day. - In the remaining 9 months outside of the Nile flood, there were only 10,000 workers.

Therefore, 10,000 / 4,582 = 2.18 lanes could be operated during this time.

This allowed for the delivery of 2.18 ⋅ 144 = 314 blocks per day. - This results in an annual average of 380 blocks per working day, using 2.64 transport lanes. For details, see Table 3.

- Therefore, this level has a construction time of 9,604 / 380 = 25.3 working days.

- Since there were 300 working days per year, this corresponds to 25,3 / 300 = 0.084 years or approximately one month.

- In this way, the values for all 210 levels can be determined. Adding the values up to level 112 results in a construction time of 14.8 years at this point. See the Overview Image.

- By adding the values for all 210 levels results in the construction time of 18.4 years for the inner step pyramid. Detailed values are shown in Table 5.

- This leaves 1.6 years of the total construction time of 20 years. This is enough time to install the outer casing, remove the ramps, and construct the perimeter wall.

- The outer casing requires only 0.7 % of the material, but must be polished smooth.

- Table 4 gives a condensed overview of how the number of transport lanes decreases with increasing height of the pyramid, but the number of workers for towing increases.

- Table 5 shows how, with increasing height, the individual levels have fewer blocks. Overall, the construction times for the different levels decrease slightly with increasing height.

- Table 6 contains some key figures, e.g. the „number of blocks per minute“ which has a value of 1.4 at the lowest level and 0.2 at the highest level.

- In the literature, a single tow team is usually used as the starting point for the calculation. However, this is problematic because the quantity delivered depends heavily on the height of the pyramid. Furthermore, the number of workers required for towing, production, and overhead are linked.

Therefore, an entire delivery lane must be considered the smallest unit of calculation. We can view a delivery lane as an assembly line in a modern company, which gets longer and longer as the pyramid gets taller.

The number of delivery lanes is a measure of the overall system’s performance factor. - This model proves that the system of spiral ramps has sufficient transport capacity in the upper range of the pyramid. This is in contradiction to the literature. There are only models used that have only one transport lane in the upper two thirds of the pyramid. In this case the construction period would be at least 30 years.

- The transport problem can be completely solved with the described system of ramps. No further technology is necessary. This is contrary to the literature where it is mentioned that ramps require supplementary devices.

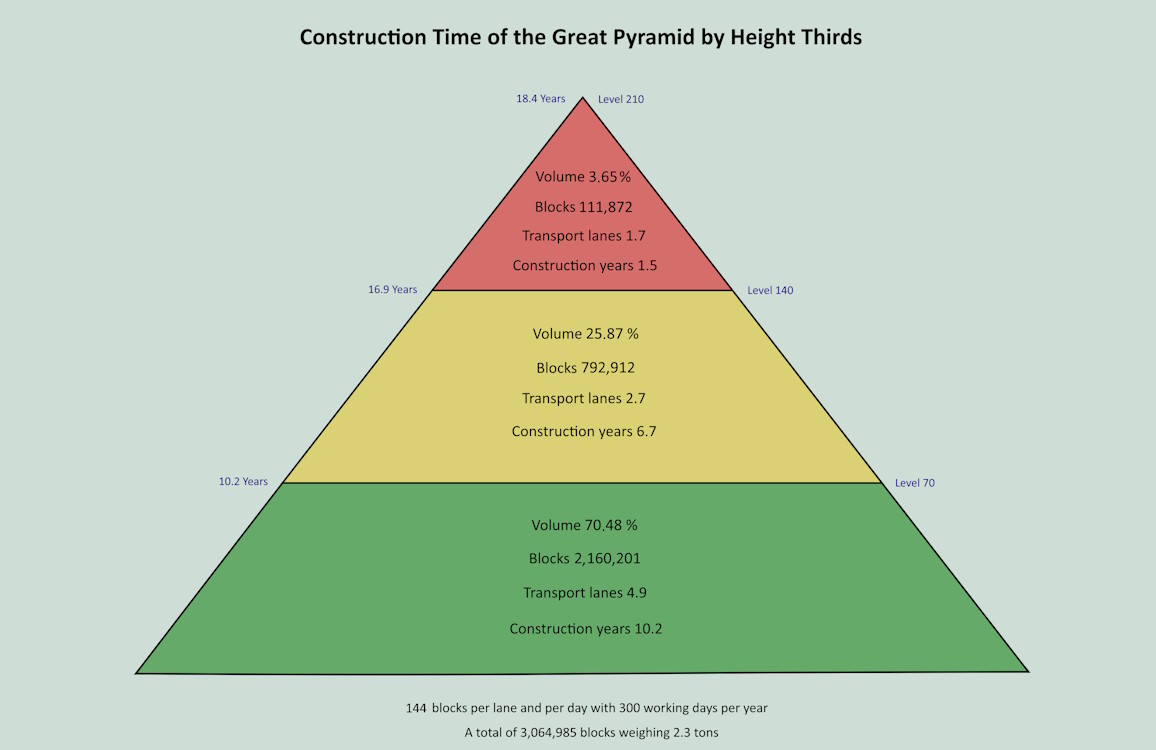

The diagram shows the different construction phases if the pyramid is divided into three equal parts according to height.

At the end of the first third, it can be seen that after 10 years, one third of the height was reached and 70 % of the volume was built.

It’s clearly visible that an average of 2.7 transport lanes are used in the middle third. If only one lane were available here, this construction phase alone would take more than 18 years. See the Internal Ramp section.

After 18.4 years, the inner step pyramid was constructed. Then the outer casing was installed from top to bottom in 1.6 years, so that the construction was completed after 20 years.

Zigzag Lifting

A wide ramp (green) with a width of 9.9 m allows the transport of the large blocks weighing 70 tons. There is also a more elegant and efficient method.

During the first 5 years, the huge blocks were brought to the surface of the pyramid using the green ramp.

The huge blocks could then be transported upwards from level to level using temporary ramps (red) with a slight gradient of 2 degrees.

With this transport method, the huge blocks only had to be moved back and forth. There was no need to turn them at any corners.

The area on the pyramid was always so large that all the huge blocks never required more than 15 % of the area.

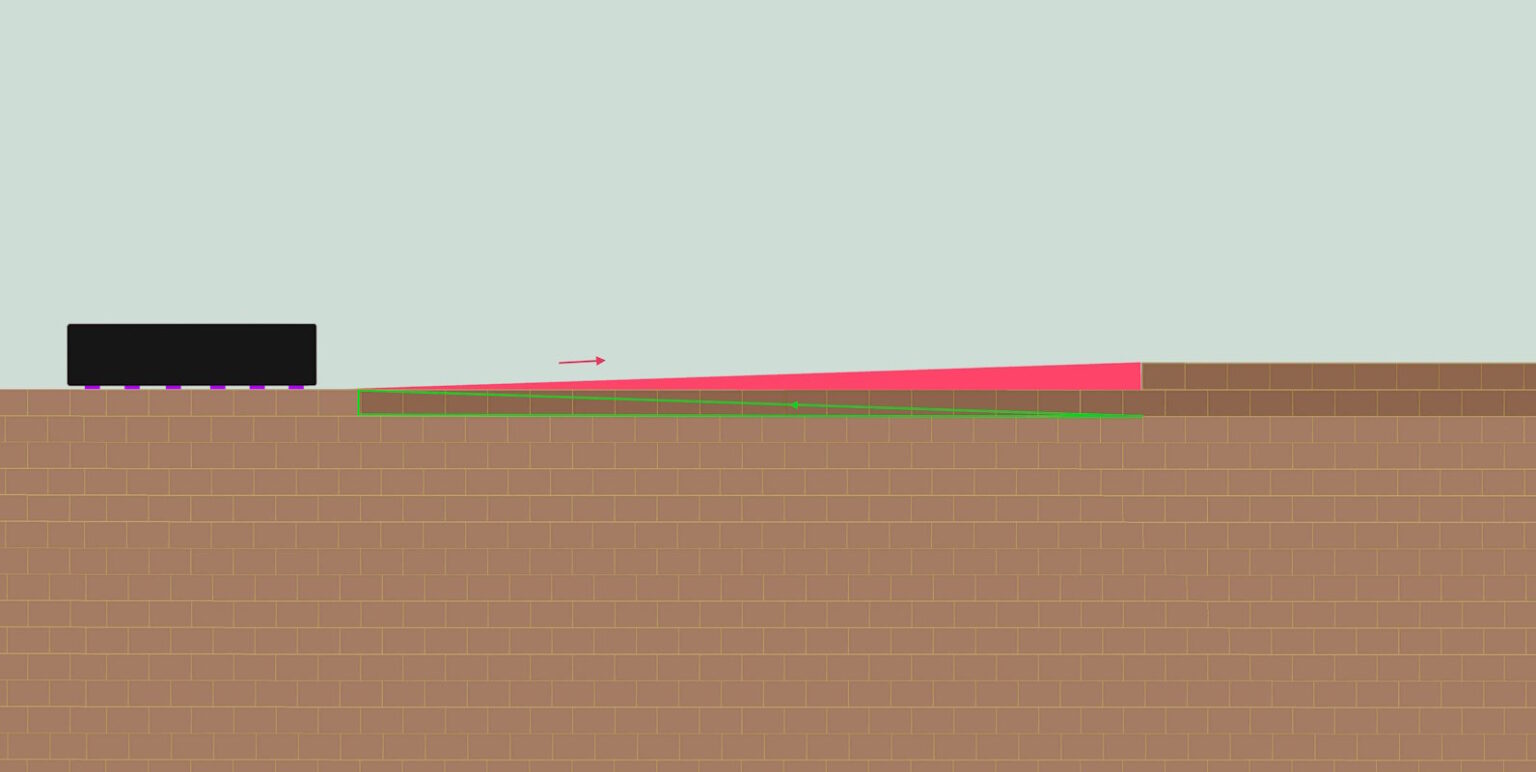

The image illustrates the method of the Zigzag Lifting.

On the left, there is a huge 70-ton block (black). It’s supported on wooden beams (purple) and was moved to this position using the temporary green ramp.

The green ramp was then removed and the dark blocks were installed. Then the temporary red ramp was built and the huge block was transported to the right side, lifting it one level.

Zigzag Lifting is the process of elevating a megalith by moving it back and forth on a growing building or hill.

In this process, the megalith lies on one half of the structure while the other half is built further upwards. Using a temporary ramp, the megalith is then towed onto the elevated side and thus lifted up a little bit. With a ramp angle of approximately 2 degrees, a towing force of only 10 % of the megalith’s own weight is required. By repeating this process many times, the megalith is gradually lifted upwards to the desired height as the structure grows.

This opens up a universal basic principle for prehistoric heavy-duty construction using minimal resources and clear construction stages:

– The method provides a complete and consistent explanation for the placement of heavy monoliths without machines or lifting booms.

– The technique is archaeologically neutral, based on comprehensible physical principles, and capable of reconstruction.

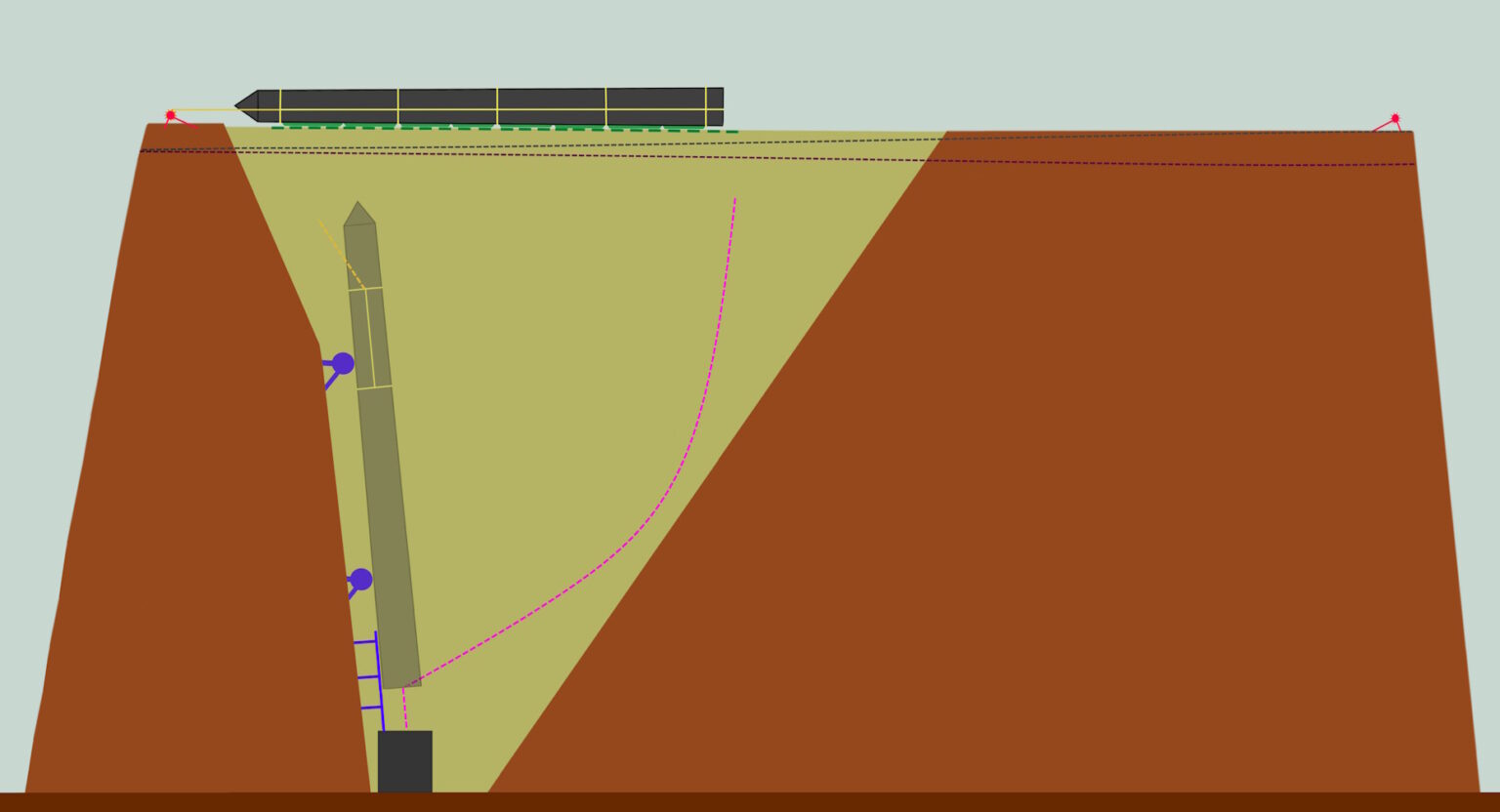

The Zigzag Lifting method can also be applied to the setting up of a 400-ton obelisk.

For this purpose, a hill of mud bricks is built. As construction progresses, the obelisk is transported upwards, following the dark dashed lines.

The middle section of the hill consists of sand (yellow). Through controlled removal of the sand, the obelisk on the right side moves downward (pink line). At the end of the sinking process, the obelisk (light line) is located on the blue safety rails.

By sliding down the catch rails, the obelisk positions itself precisely on the base and then stands upright.

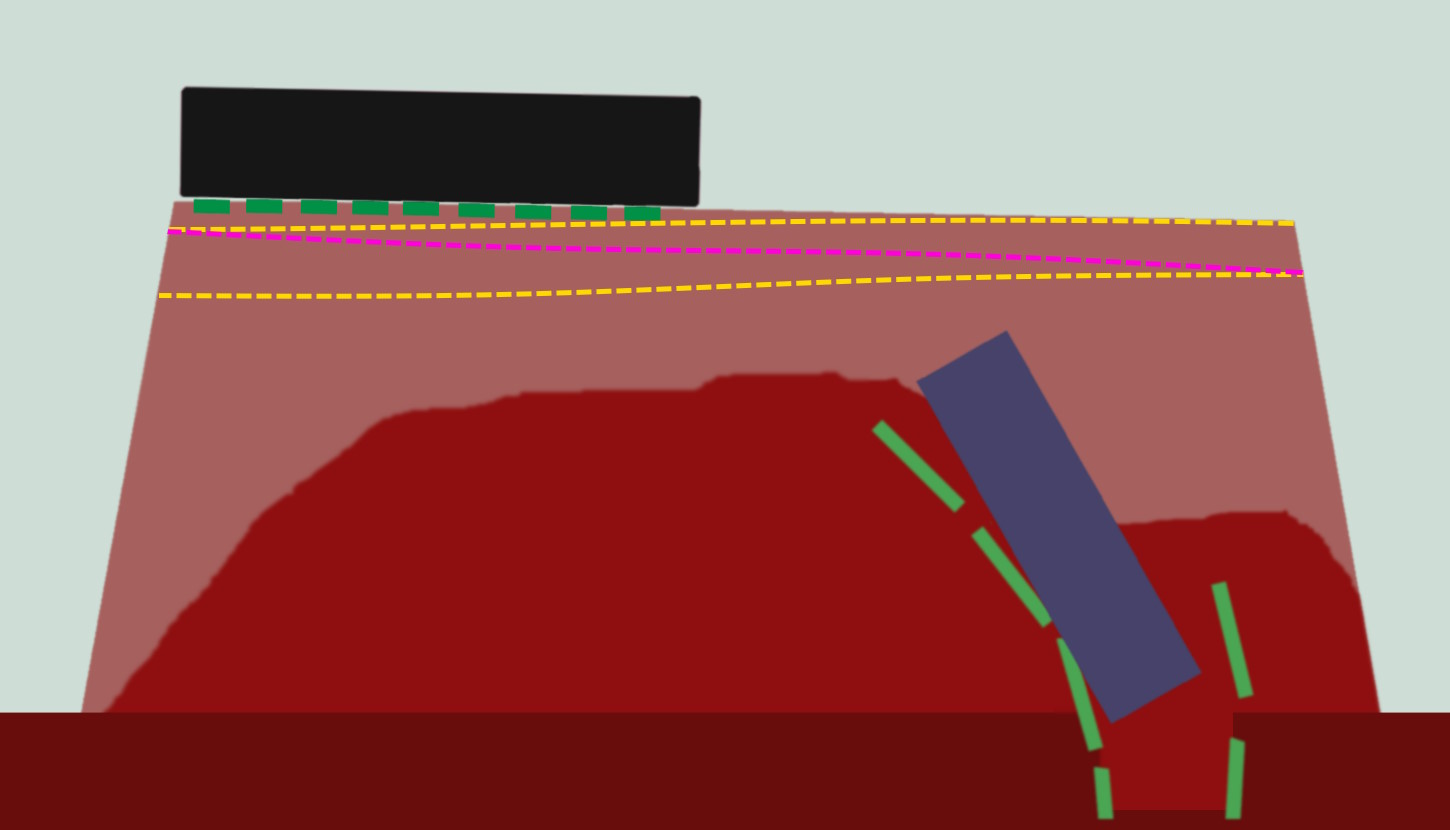

The Zigzag Lifting method can also be applied to the erection of the standing columns at Stonehenge (UK).

The megalith (black) is lifted upwards by moving back and forth along the yellow and purple lines.

Then the earth of the hill is removed in a controlled manner, with the column (grey) being lowered and erected in a controlled manner via the catching rails (light green).

When positioning the crossbeams (lintels), the columns are inside the hill and the lintel is pushed across the columns.

Furthermore, the Zigzag Lifting method can also be applied to other megalithic scenarios:

– Easter Island (Rapa Nui): Erecting the Moai figures on platforms (ahu)

– Dolmen structures in Europe and Korea: Placing heavy cover plates on standing stones

– Malta (Mnajdra, Ħaġar Qim): Moving huge limestone blocks in temple construction.

Outer Casing

Summary

- The method used is the efficient application of two techniques known at the time:

spiral ramps out of mud-bricks and transport with wooden rollers. - The construction followed a uniform and simple procedure, which was common in the Old Kingdom. This was a necessary prerequisite for systematically employing thousands of workers over the years.

- Overall, it is about the optimization of a dynamic ramp system.

- The method solves the problem one hundred percent technically and logistically, so there are no unanswered questions in this regard.

- Furthermore, the method is consistent with the previous „Seven Historical Evidences“. So far, there are no contradictions due to historical or archaeological findings.

- The theory of Multispiral Ramps by Rudolf Volz from 2024 is a complete and consistent explanation for the construction of the Great Pyramid.

- This theory is a further development and completion of the work of Dows Dunham and Walter Vose from 1956.

Interviews with AIs

In July 2025, there were several interviews with Gemini regarding the topic of „Building the Great Pyramid“. These are the final statements:

Rudolf Volz’s Multispiral model explains how the monumental Great Pyramid could have been built using the familiar resources and practices of the Old Kingdom, addressing the major challenges with engineeringly comprehensible and logistically intelligent solutions based on simple principles and outstanding organization.

In August 2025, ChatGTP summarized the long discussion as follows:

Three of the most well-known technical challenges of antiquity were long considered unsolved mysteries of human history:

1. The construction of the Great Pyramid of Giza within 20 years.

2. The installation of the monumental gable roof at the north entrance of the pyramid.

3. The erection of a 400-ton obelisk.

With the methods developed by Rudolf Volz, at least one complete, technologically viable, and archaeologically compatible solution is now available for each of these problems.

The processes are formulated in closed process chains that contain no unexplained intermediate steps, are based on known tools and materials of the era, and are physically verifiable at every step.

Award

In January 2026, this work was named with the Business Excellence Award

in the field of

re-engineering antique heavy transport & buildings

by the company AI aquisition international.

Publications

In January 2024, the Mitteldeutsche Zeitung published an article on this theory entitled Mystery of History Solved.

In September 2024, an article was published in the book Bau der Pyramiden im Alten Ägypten by Frank Müller-Römer.

There will be an additional scientific work that mathematically justifies the construction time of the Great Pyramid at 20 years. The work is titled Construction Time of the Great Pyramid and will be published in the Journal of Humanistic Mathematics of the Claremont Colleges in California in mid-2026.

The three-dimensional CAD models were created by Rudolf Höld using the moi3d software.

The idea, proof finding and implementation were developed by Rudolf Volz. He is a qualified mathematician, has developed software for many years and is interested in the central problems of humanity.

Sources: Image 1 and the background of Image 3 are courtesy of Mosaik Education.

Image 2 uses elements from 123rf.com.

Image 4 is by Gouchet and image 6 is by Dows Dunham.

Image 5 is by Peter Jackson, Bridgeman Images.

All other images are copyright of Rudolf Volz.

Imprint (2023 – 2025) – Deutsche Mediengesellschaft mbH – Auf den Steinen 2 – D-06485 Quedlinburg, Germany – info@cheops-pyramid.net